Process method for preparing methyl tert-butyl ether by differential reaction rectification and equipment for same

A technology of methyl tert-butyl ether and differential reaction, which is used in the preparation of ether by addition of unsaturated compounds, ether preparation, organic chemistry, etc., which can solve the problems of inability to enter liquid in time, flooding of trays, and large bed resistance. , to achieve the effect of improving the reaction conversion rate and separation efficiency, improving the utilization rate of the tray area, and accelerating the mass transfer and liquid distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

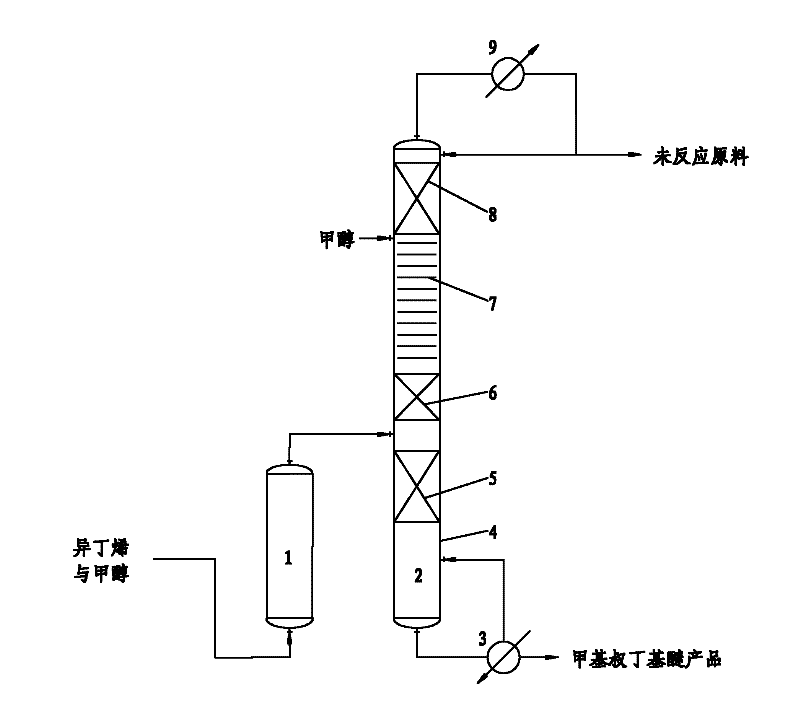

[0019] Embodiment 1: use above-mentioned equipment and process method to prepare methyl tert-butyl ether, wherein:

[0020] The ratio of methanol to isobutene: 1.1:1;

[0021] Fixed bed reaction conversion rate: 90%;

[0022] Catalytic reaction distillation column operating pressure: 0.3MPa;

[0023] Operating temperature: 10~70℃;

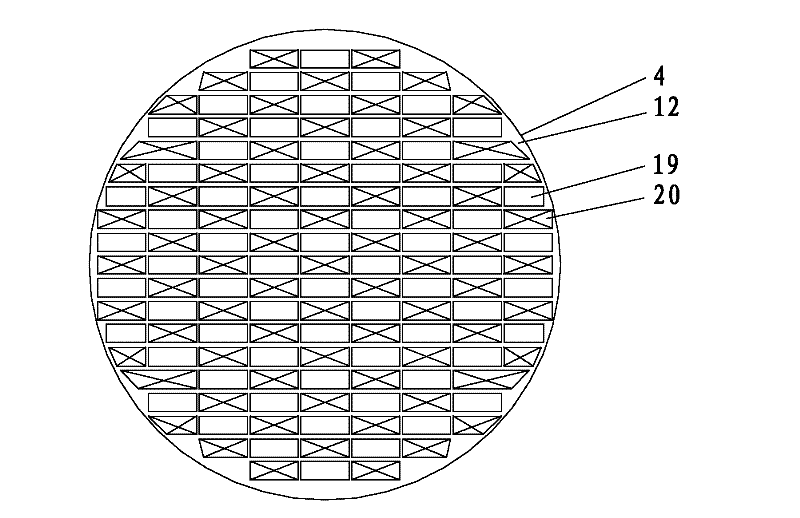

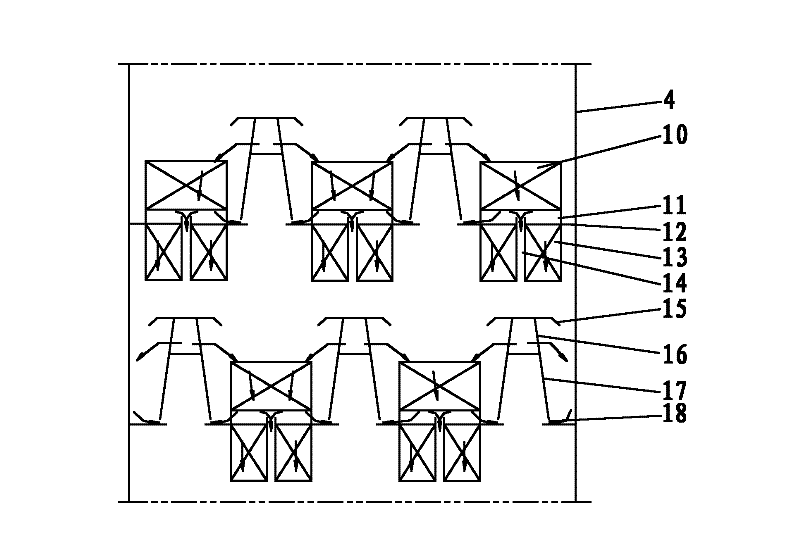

[0024] Structural type of catalytic reaction distillation tower (from top to bottom): 3m high-efficiency structured packing + 30 layers of differential catalytic reaction distillation trays + 3m high-efficiency structured packing + 5m high-efficiency structured packing;

[0025] Isobutene content (mol%) at the top of the tower: 0.1%;

[0026] Purity (mol%) of methyl tert-butyl ether at the bottom of the tower: 98%;

[0027] Isobutene conversion: 99%.

Embodiment 2

[0028] Embodiment 2: use above-mentioned equipment and process method to prepare methyl tert-butyl ether, wherein:

[0029] The ratio of methanol to isobutene: 1.1:1;

[0030] Fixed bed reaction conversion rate: 90%;

[0031] Catalytic reaction distillation column operating pressure: 2.0MPa;

[0032] Operating temperature: 50~180℃;

[0033] Structural type of catalytic reaction distillation tower (from top to bottom): 18 layers of valve trays + 30 layers of differential catalytic reaction distillation trays + 18 layers of valve trays + 30 layers of valve trays;

[0034] Isobutene content (mol%) at the top of the tower: 0.1%;

[0035] The purity of methyl tert-butyl ether at the bottom of the tower (mol%): 98.5%;

[0036] Isobutene conversion: 99.3%.

Embodiment 3

[0037] Embodiment 3: use above-mentioned equipment and process method to prepare methyl tert-butyl ether, wherein:

[0038] The ratio of methanol to isobutene: 1.1:1;

[0039] Fixed bed reaction conversion rate: 90%;

[0040] Catalytic reaction distillation column operating pressure: 0.8MPa;

[0041] Operating temperature: 40~130℃;

[0042] Structural type of catalytic reaction distillation tower (from top to bottom): 3m high-efficiency structured packing + 30 layers of differential catalytic reaction distillation trays + 3m high-efficiency structured packing + 30 layers of valve trays;

[0043] Isobutene content (mol%) at the top of the tower: 0.1%;

[0044] The purity of methyl tert-butyl ether at the bottom of the tower (mol%): 98.5%;

[0045] Isobutene conversion: 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com