Film type heat insulation box for liquefied natural gas ship and construction method thereof

A liquefied natural gas, film-based technology, applied in ship construction, ship components, ship design, etc., can solve the problems of high water absorption of glass wool, long construction and installation period, high water vapor passing rate, and achieve overall light weight and reduce transportation. cost, the effect of reducing the cost of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

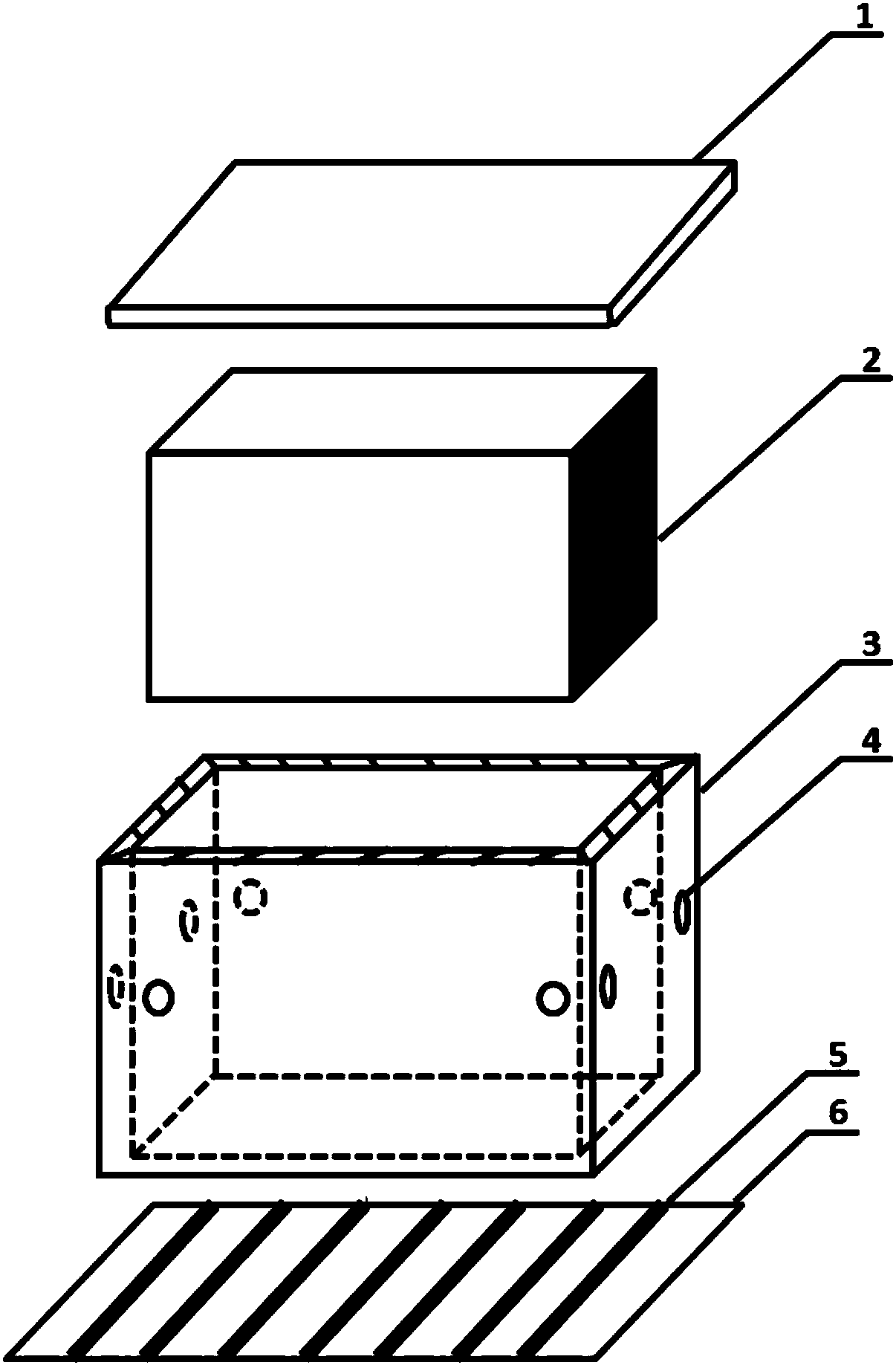

[0063] Such as figure 1 As shown, the composition of the film-type liquefied natural gas marine insulation box of this embodiment includes a plywood panel 1, a rigid polyurethane foam board 2, and a plywood assembly box 3; Holes 4; the assembled heat insulation box is fixedly bonded with the inner hull 6 of the ship through the viscous resin rope 5;

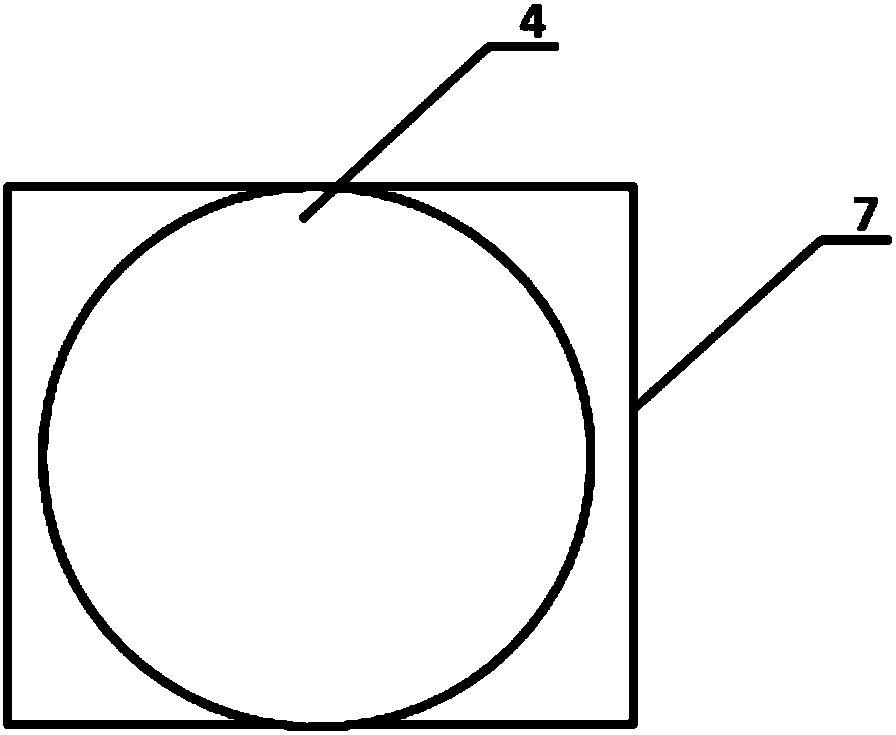

[0064] Such as figure 2 As shown, paste with glass cloth 7 on the drilled hole 4;

[0065] The surface of the plywood panel on the heat insulation box is covered with a dense metal film welded by invar steel or 9% nickel steel; the size of the heat insulation box is 1200mm×1000mm×530mm (length×width×thickness).

[0066] The construction method includes the following steps:

[0067] Take the unnoded part of the trunk center of birch in the frigid zone and cut it into single pieces, and then heat-press through steps such as gluing and billeting to obtain plywood, with a thickness of 12mm;

[0068] Rigid polyurethane foam board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com