Combined paddle stirring device

A stirring device and combined paddle technology, which is applied in the field of combined paddle stirring devices, can solve the problems of poor axial and radial mixing ability, increase axial displacement, increase mixing rate, and solve problems of poor axial mixing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

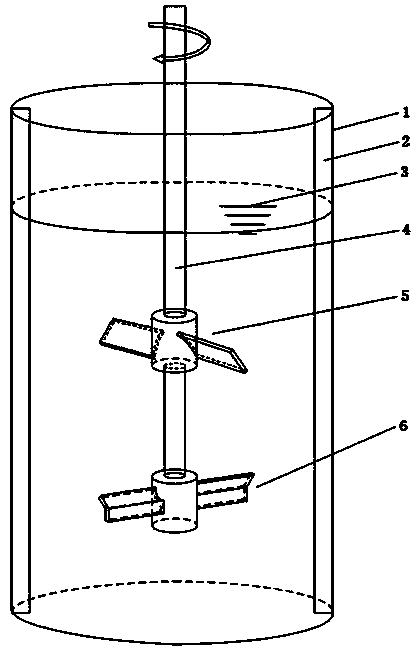

[0038] Be that 240mm, height be in the flat-bottomed cylindrical stirring tank 1 of 400mm in groove diameter, investigate the combined paddle stirring device provided by the present invention (as figure 1 Shown) and double-deck Rushton paddle stirring device in the prior art (as Figure 4 Shown) power consumption per unit volume. Four baffle plates 2 are installed vertically and evenly on the inner wall of the stirring tank 1, and the width of the baffle plates 2 is 24mm. The tap water liquid level height in the tank is 288mm, the bottom height of the lower Rushton paddles 7 is 60mm, and the paddle pitch of the upper and lower Rushton paddles 7 is 140mm.

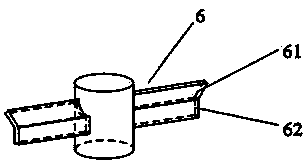

[0039] see figure 1 , the upper paddle is a slanted paddle 5 with two blades pressed down by 45°, the paddle diameter of the slanted paddle 5 is 94mm, and the blade width is 24mm; 94mm, wherein: the width of the inclined folding paddle 61 and the vertical folding paddle 62 is 12mm, and the angle between the inclined foldi...

Embodiment 2

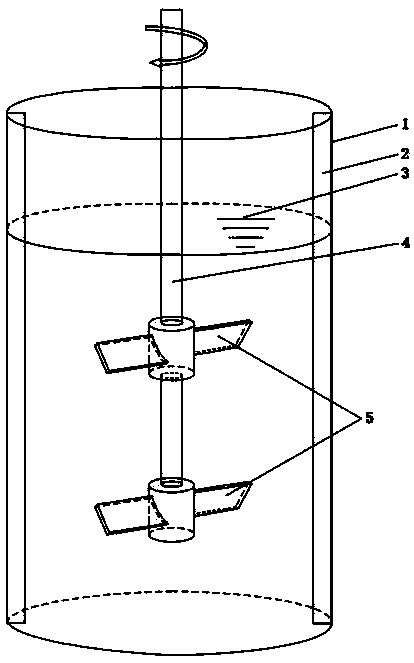

[0044] For the liquid-solid two-phase system, the structure and size of the stirring tank 1 of the present embodiment are the same as those in Embodiment 1, the liquid phase still selects tap water, and the solid phase is glass beads with a particle diameter of 2.0 ± 0.1 mm (density 2.817g / cm 3 ), the range of solid phase volume fraction is 0.1%~5%, investigate respectively the combined paddle stirring device provided by the present invention, the double-layer pitched paddle stirring device in the prior art (such as image 3 Shown) and the corresponding critical off-bottom suspension stirring speed of solid particles in the double-layer Rushton paddle stirring device in the prior art under different solid holdups. see figure 2, the upper and lower floor paddles are the oblique blade paddle 5 that the two blades press down 45°, and the paddle diameter of the oblique blade paddle 5 is 94mm, and the blade width is 24mm. The critical off-bottom suspension stirring speed is the m...

Embodiment 3

[0048] The structure and size of the stirring tank 1 of the present embodiment are the same as in the second embodiment, and the mixing time of the single-phase liquid phase system of the combined paddle stirring device provided by the present invention and the double-layer pitched blade stirring device in the prior art is measured by the conductivity method . The sodium chloride solution with a concentration of 15% is used as a tracer, and it is added to the vicinity of the liquid surface of the stirring tank 1 in an instant, and at the same time, the data acquisition card is used to convert the conductivity value of the monitoring point measured by the conductivity meter into an electrical signal, and the signal is recorded by the computer Variation curve over time. In the experiment, the monitoring point and the feeding point are located on the same plane, but on both sides of the stirring shaft 4. The mixing time characterizes the mixing efficiency of the reactor scale in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com