Direct-drive traction motor rotating shaft sleeving device and method

A technology for traction motors and shafts, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high cost, unsatisfactory, and failure to use hydraulic presses, etc., to achieve reduced damage, small press-fitting displacement, and packaging process Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

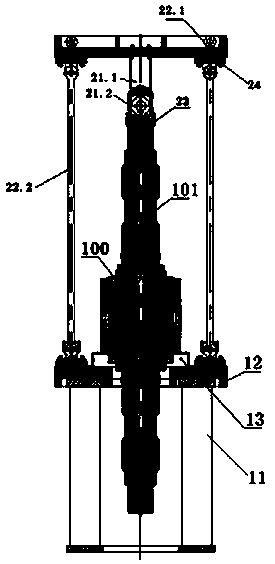

[0030] Combine below Figure 1 to Figure 6 Embodiments of the present invention are described in detail.

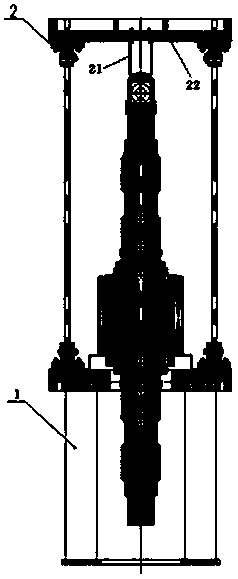

[0031] Direct drive traction motor rotating shaft assembly device, including supporting and positioning assembly 1 for supporting and positioning the rotor core 100 arranged vertically and press-fitting assembly 2 for pressing the rotating shaft 101 into the rotor core 100, the rotor core 100 is vertically arranged Positioned on the supporting positioning assembly 1, the rotating shaft 101 is lowered into the rotor core and one end extends into the supporting positioning assembly 1, the press-fit assembly 2 is coaxially connected above the supporting positioning assembly 1, and the rotating shaft 101 is aligned along the central axis of the rotating shaft 101. Press down.

[0032] The direct drive traction motor rotating shaft assembly device described above includes a support positioning assembly 1 and a press-fit assembly 2, the support positioning assembly 1 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com