Hanger for porcelain shell

A spreader and porcelain sleeve technology, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of inclination, shaking, unsafe, and difficult hoisting process of the porcelain sleeve, and achieve the effect of reliable hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Existing porcelain sleeves such as Figure 6~7 As shown: the upper end of the porcelain sleeve 12 has a cylindrical connection cap 13, and two convex connection plates 16 are symmetrically arranged on the connection cap.

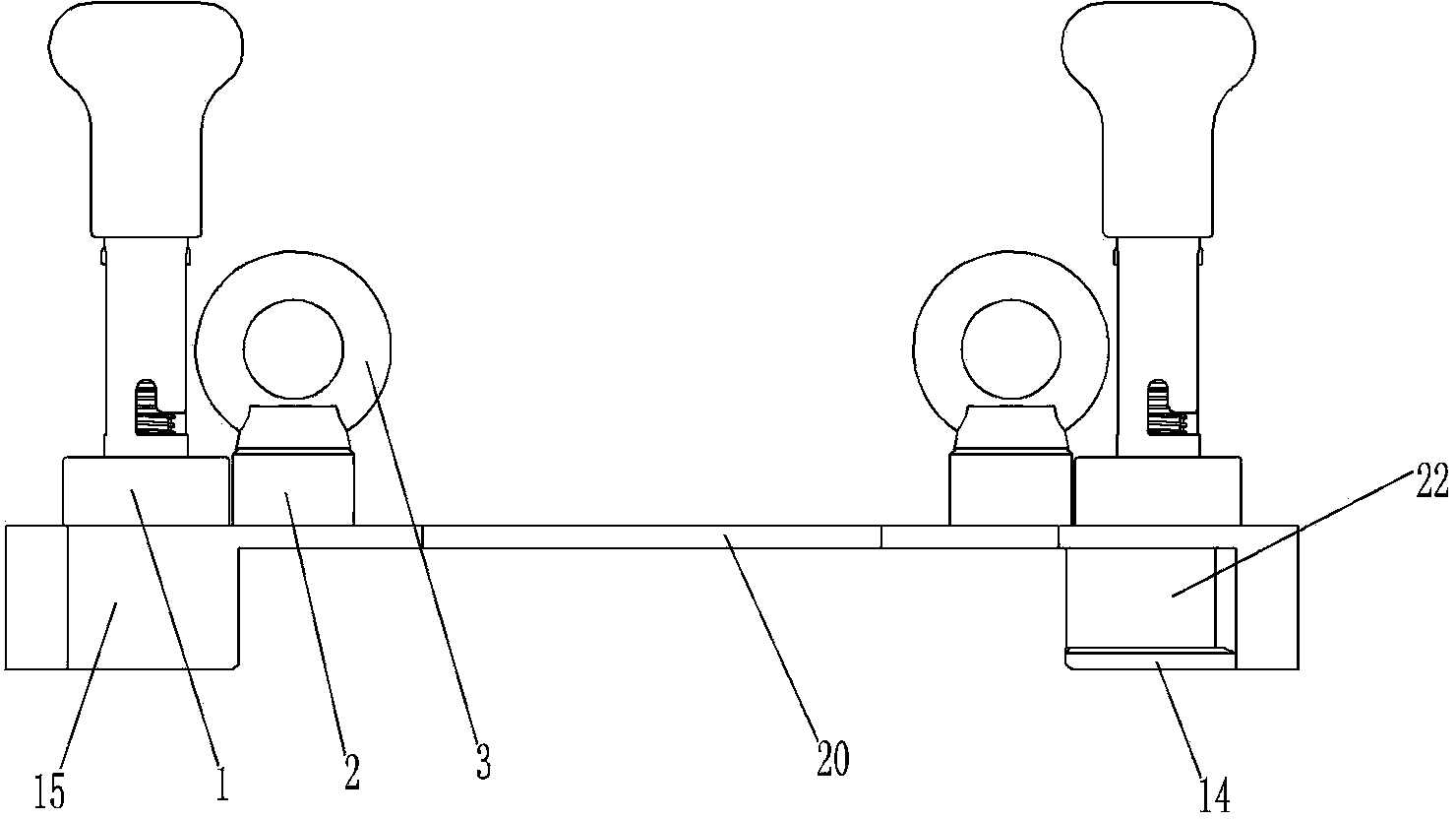

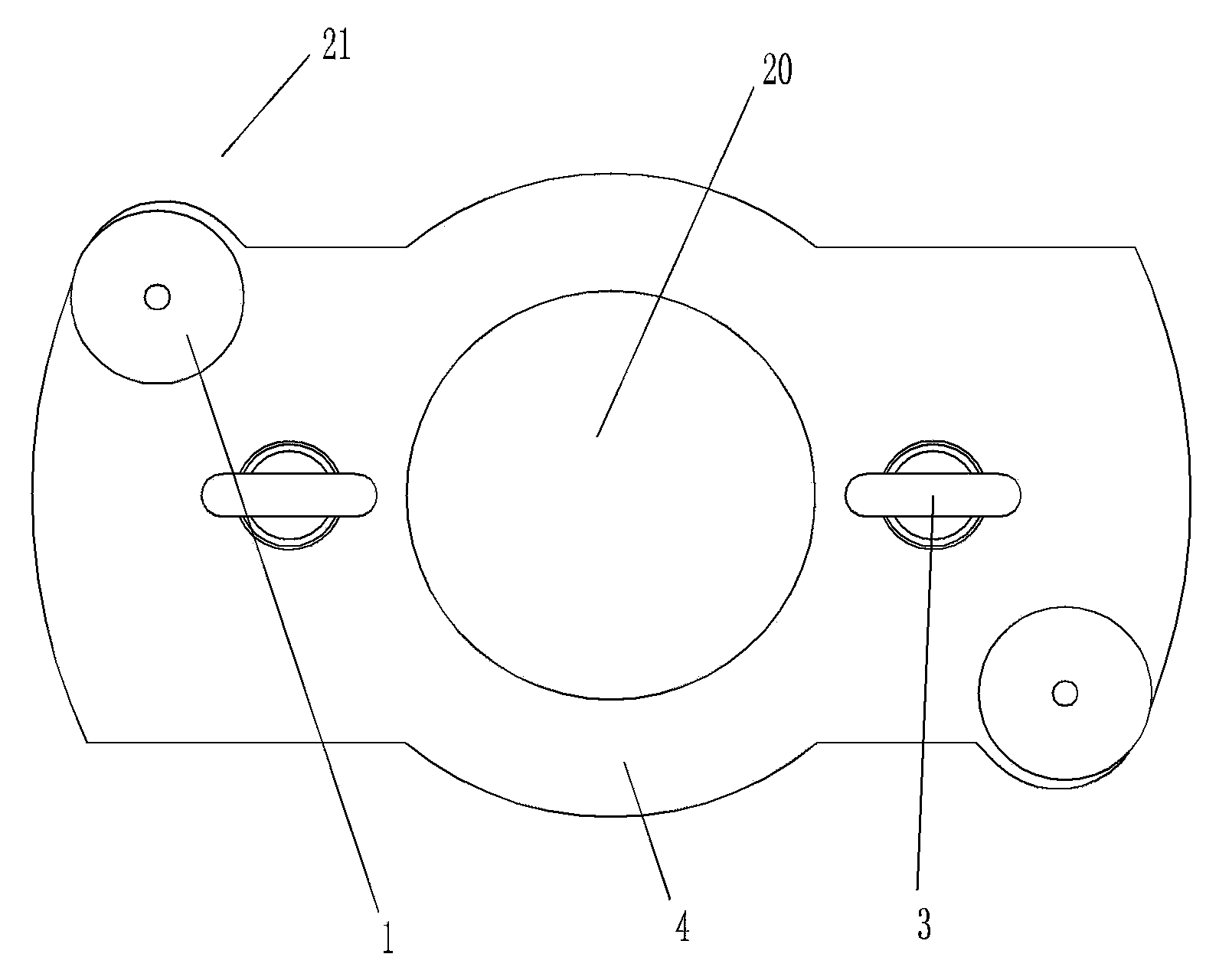

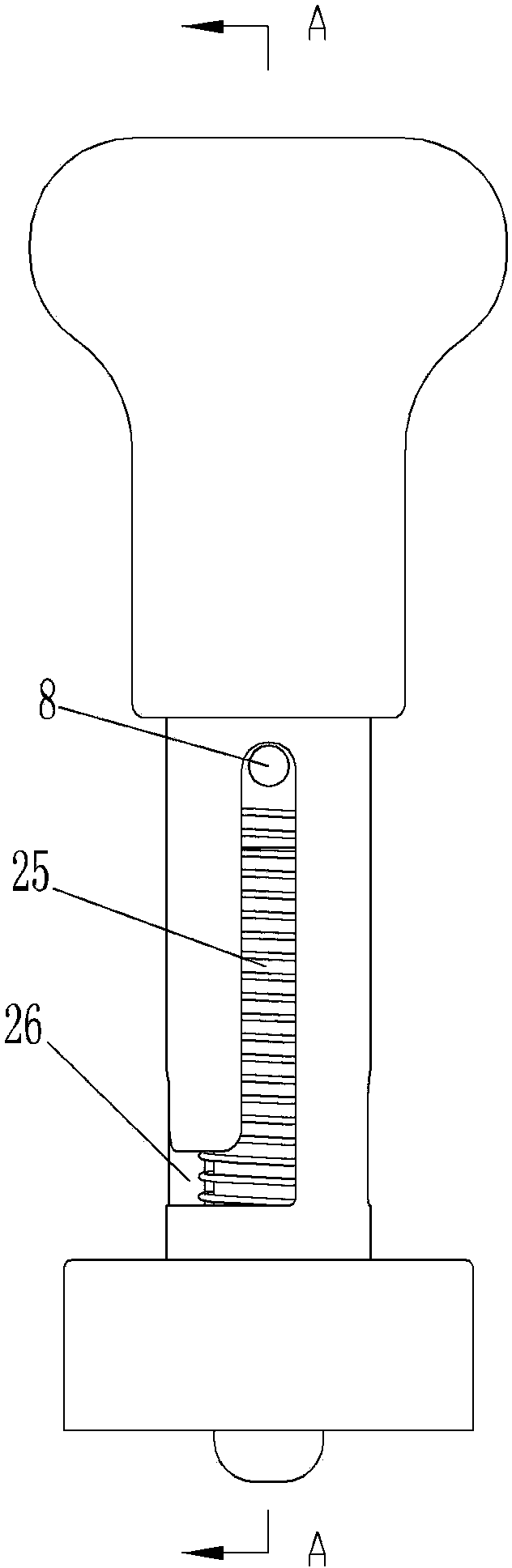

[0024] Examples of porcelain spreaders Figure 1~8 As shown: including the spreader body 4, the upper end of the spreader body is fixed with a lifting ring 3 for connecting with the corresponding lifting equipment, the lifting ring is fixed on the spreader body through a screw sleeve 2, and a positioning hole 20 is arranged on the spreader body. When the positioning hole is in use, it is rotated and positioned on the wiring cap on the upper end of the porcelain sleeve. Two support bodies 14 are fixed symmetrically under the spreader body, and the two support bodies are arranged around the circumference of the positioning hole on the periphery of the positioning hole. A circumferential gap 21 with a length greater than the axial length of the terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com