A medium frequency ultrasonic nebulizer

An ultrasonic nebulizer and intermediate frequency technology, which is applied in the field of ultrasonic atomization technology, can solve the problems of increasing the working frequency, small atomization volume, and short life, and achieve the effects of increasing atomization volume, increasing reliability, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

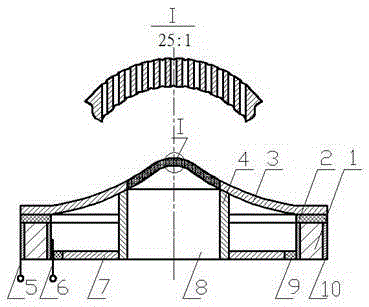

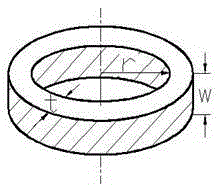

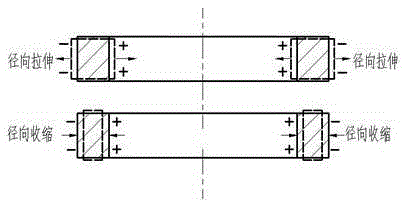

[0024] Such as figure 1 with figure 2 As shown, the piezoelectric ceramic 1 is a thin-walled metal ring whose radial thickness t is smaller than its axial thickness w and the inner circle radius r of the ring. The inner and outer walls of the piezoelectric ceramic 1 are both coated with a silver layer 10. The upper end surface of the upper insulating ring 2 is pasted together with the lower end surface of the horizontal annular part of the metal end cap 3, and the lower end surface is pasted together with the upper end surface of the piezoelectric ceramic 1. The shape of the metal end cap 3 is a spiral line, and the center of the metal end cap 3 has a laser through hole made by laser. The position corresponding to the laser through hole area on the lower end surface of the metal end cap 3 is connected to the central metal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com