Control method of combustion system, combustion system and diesel engine

A combustion system and control method technology, applied in fuel injection control, electrical control, engine control, etc., can solve the problems of limited diesel engine power output, poor oil-gas mixing effect, weakened entrainment effect, etc., to improve combustion speed and in-cylinder Optimum effects of air utilization, rate increase, and power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

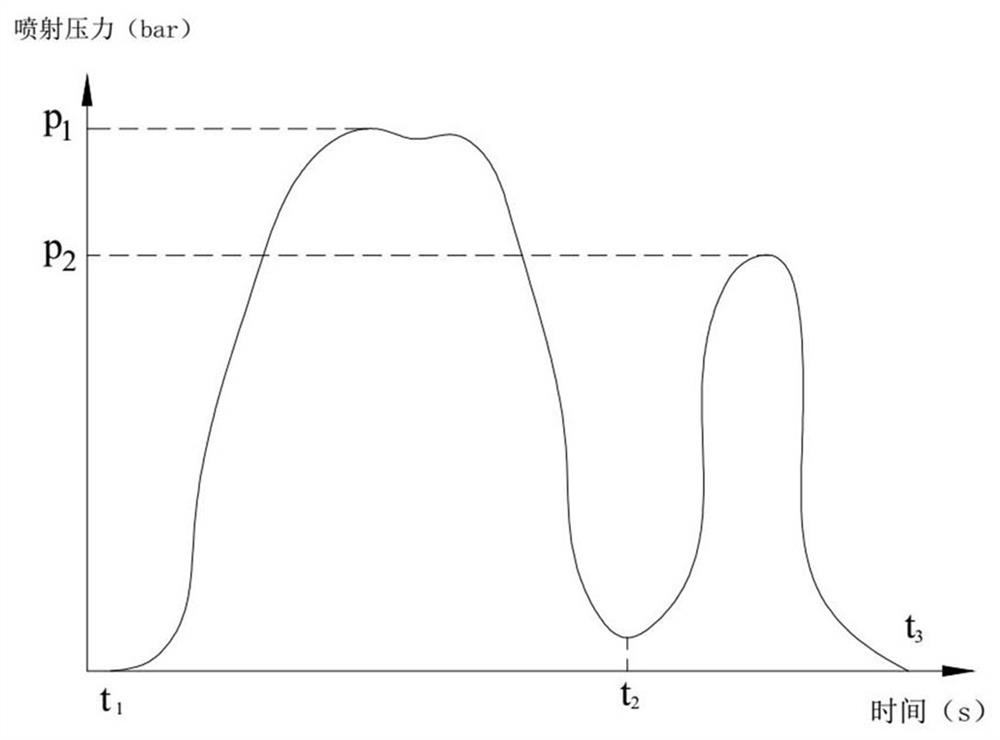

[0052] This embodiment provides a combustion control system, a combustion control system comprising a piston, injector, and a cylinder, wherein the piston can be moved up and down in the cylinder, and the injector is used to spray the fuel in the combustion chamber disposed of the piston. The combustion control system also includes a controller for controlling the injector at least the first main fuel injection and the second main fuel injection in each moving cycle of the piston, and the injector is injected in the first main fuel. In the process of the second main fuel injection, it continuously invested, and the rate of the fuel injected in the injector in the second main fuel injection and the injector is not less than the set value, the injector is in the first The rate of fuel injected between the main fuel injection and the second main fuel injection is smaller than the set value. Wherein, the controller can be connected to the control valve on the oil supply line provided ...

Embodiment 2

[0056] This embodiment provides a diesel engine, the diesel engine includes a combustion system in the first embodiment. And the diesel engine has the beneficial effect of the combustion system in the first embodiment.

Embodiment 3

[0058] This embodiment provides a control method of a combustion system, and can be implemented by the combustion system in the first embodiment. The control method of the combustion system includes:

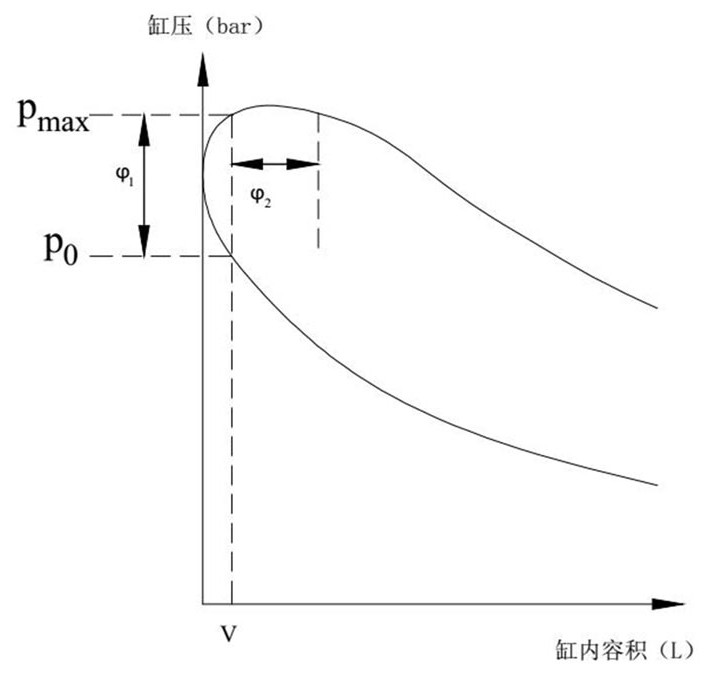

[0059] S100: Determines the continuous duration of the first main fuel injection and the first injection pressure to enable the cylinder pressure of at least part of the first main fuel injection to reach the cylinder pressure upper limit threshold.

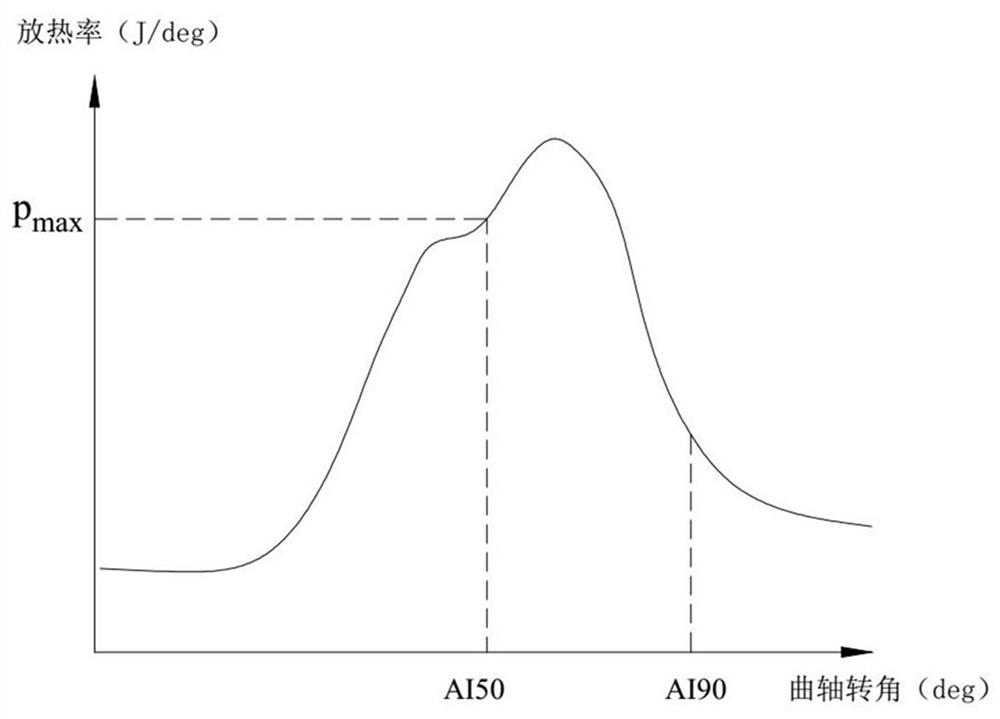

[0060] S200: Iteration Adjusts at least one of the continuous duration of the second main fuel injection and the second injection pressure to reduce the second main fuel injection, the cylinder pressure drops from the cylinder pressure to the time period set. Inside, the change rate of the curve slope of the cylinder pressure change in each time point is in the set slope change rate, and the cylinder pressure is lowered from the cylinder pressure to the crankshaft rotation of the cylinder pressure. The angle is not less than the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com