Average power control method and system for multi-module fuel cell system

A technology of a fuel cell system and a control method, which is applied in the directions of electrical components, circuit devices, AC network circuits, etc., can solve the problems of low work efficiency and shortening the service life of fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

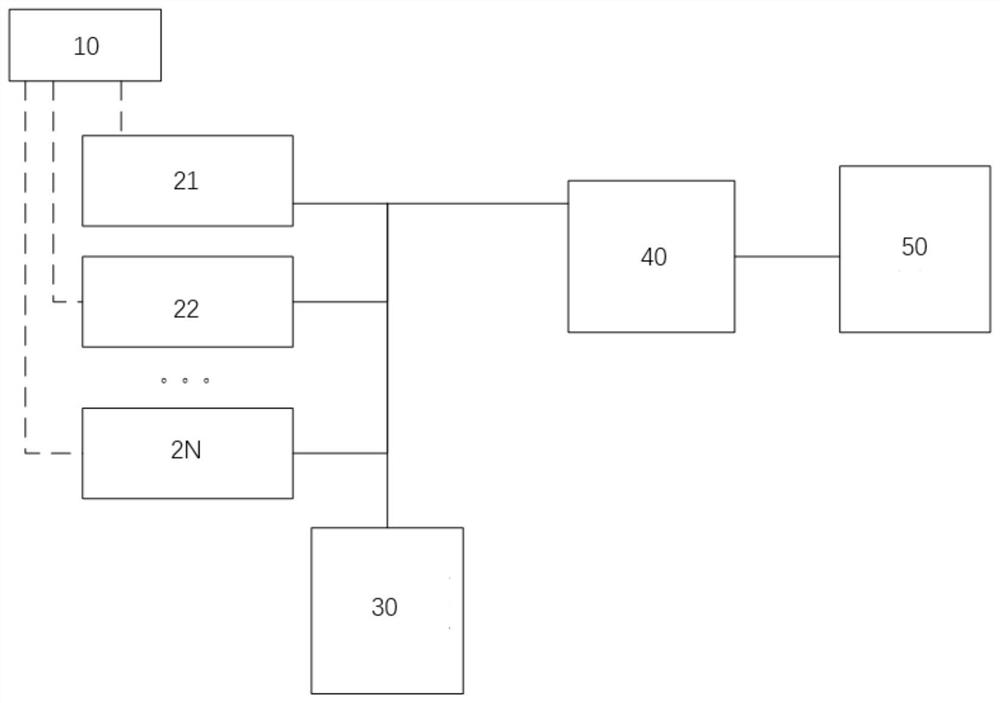

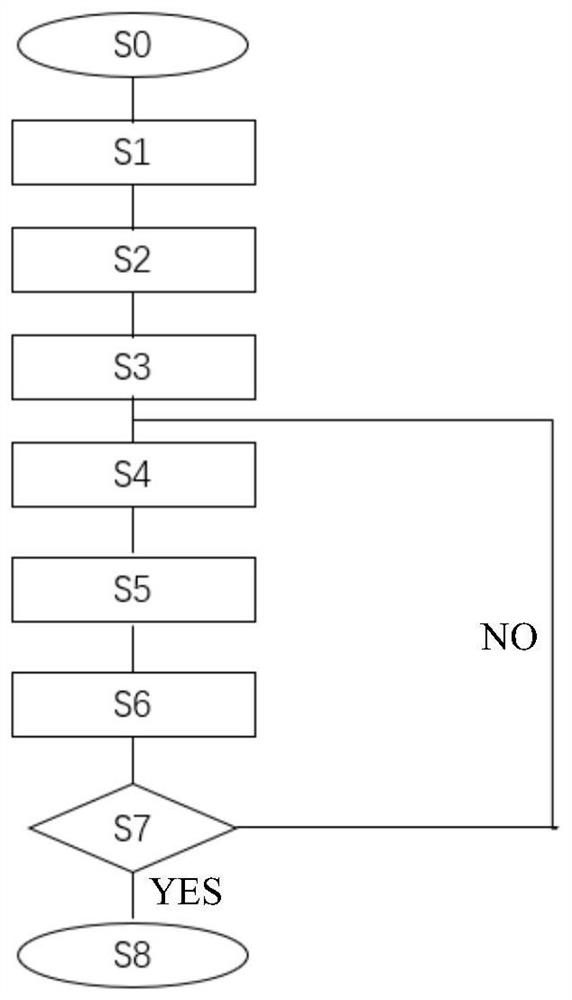

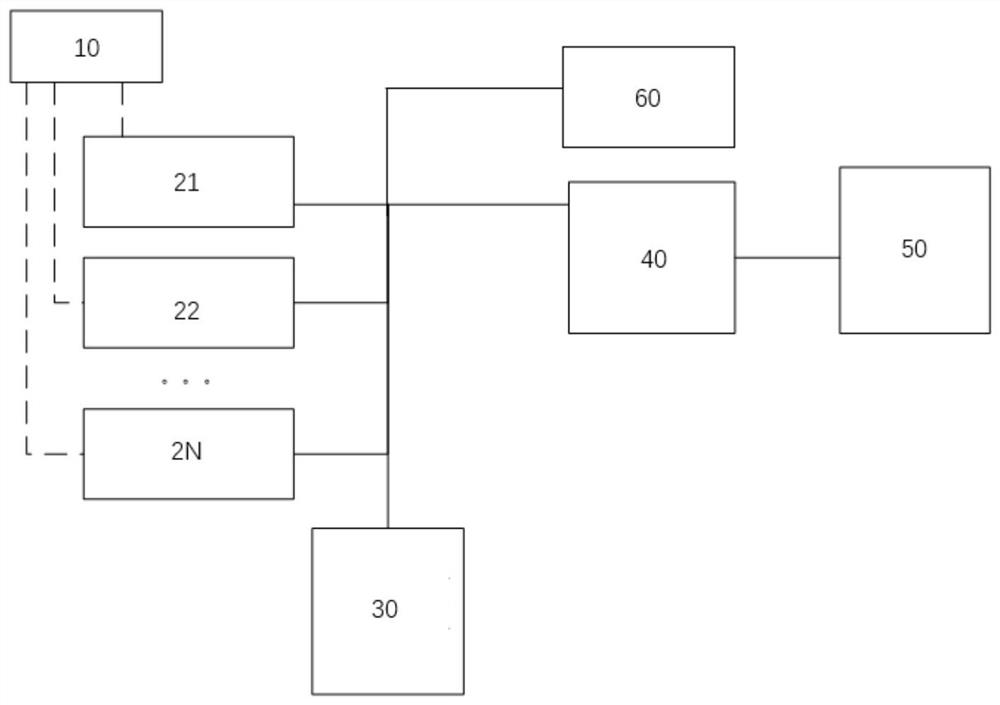

[0037] A detailed description will be given below in conjunction with the accompanying drawings.

[0038] Aiming at the deficiencies of the prior art, the present invention provides a multi-module fuel cell system average power control method and system, which can also be called a fuel cell power control method and system.

[0039] In the prior art, the best efficiency operating point of the fuel cell power generation module is 80% to 100% of the rated power. In actual use, the user's power consumption will vary due to changes in the number of load devices activated in different time periods, resulting in the real-time output power of the fuel cell may be 20%, 50% or 90%. The control module of the fuel cell system needs to manage the power and opening and closing status of the power generation module according to the real-time total power consumption, and increase or decrease the number of start-up modules of the invention in real time. In the prior art, when multiple modules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com