A Piezoelectric Wind Energy Harvester with a Resonant Cavity

A collector and resonant cavity technology, applied in the field of micro energy recovery, can solve the problems of low energy conversion efficiency, narrow working wind speed range, high critical starting wind speed, etc., and achieve the effect of simple structure, wide working wind speed range and low critical starting wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described with reference to the drawings and specific embodiments below.

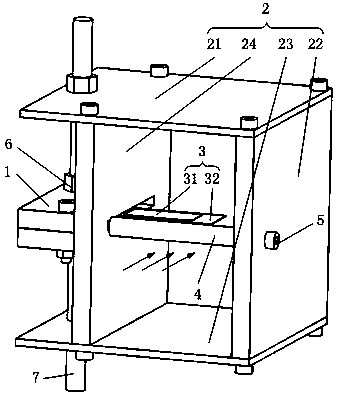

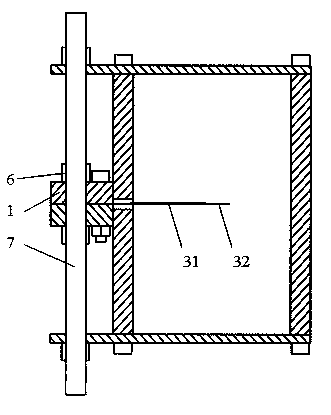

[0017] Such as Figure 1 to Figure 3 As shown, a piezoelectric wind energy collector with a resonant cavity includes a clamping plate 1, a rectangular cavity 2, a piezoelectric vibrator 3, and a column 4, and two clamping plates 1 fix one end of the piezoelectric vibrator 3 by bolts , the other end of the piezoelectric vibrator 3 extends into the rectangular cavity 2 in a free state; the column 4 is fixed on the rectangular cavity 2 by screws 5, and is located in front of the piezoelectric vibrator 3, close to the rectangular cavity 2 At one end of the tuyere, the rectangular cavity 2 is fixed on a long stud 7 through a nut 6 .

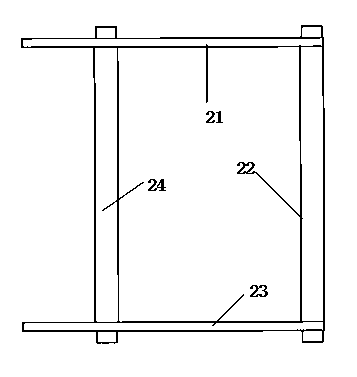

[0018] Described rectangular cavity 2 is formed by upper plate 21, lower plate 23, right side plate 22, and left side plate 24 is connected by hexagon socket head cap screw, and it has an air inlet and an air outlet, and described l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com