Printing ink hot-stirring device

A technology of mixing equipment and ink, which is applied to mixer accessories, mixers with rotating mixing devices, and dissolving directions, can solve the problems of poor ink mixing effect, slow material mixing speed, and ink coking, etc., to improve mixing efficiency and strong power. , the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

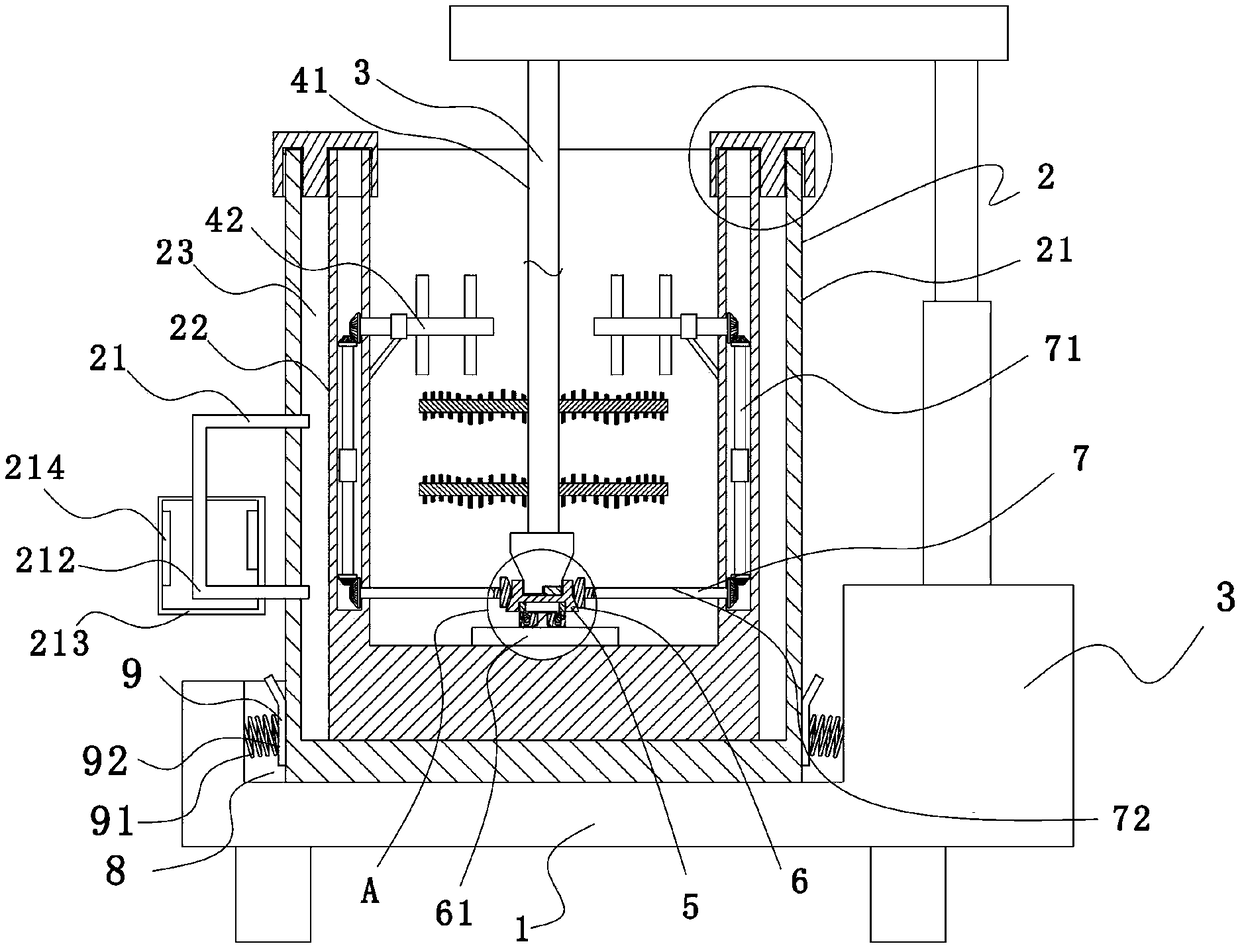

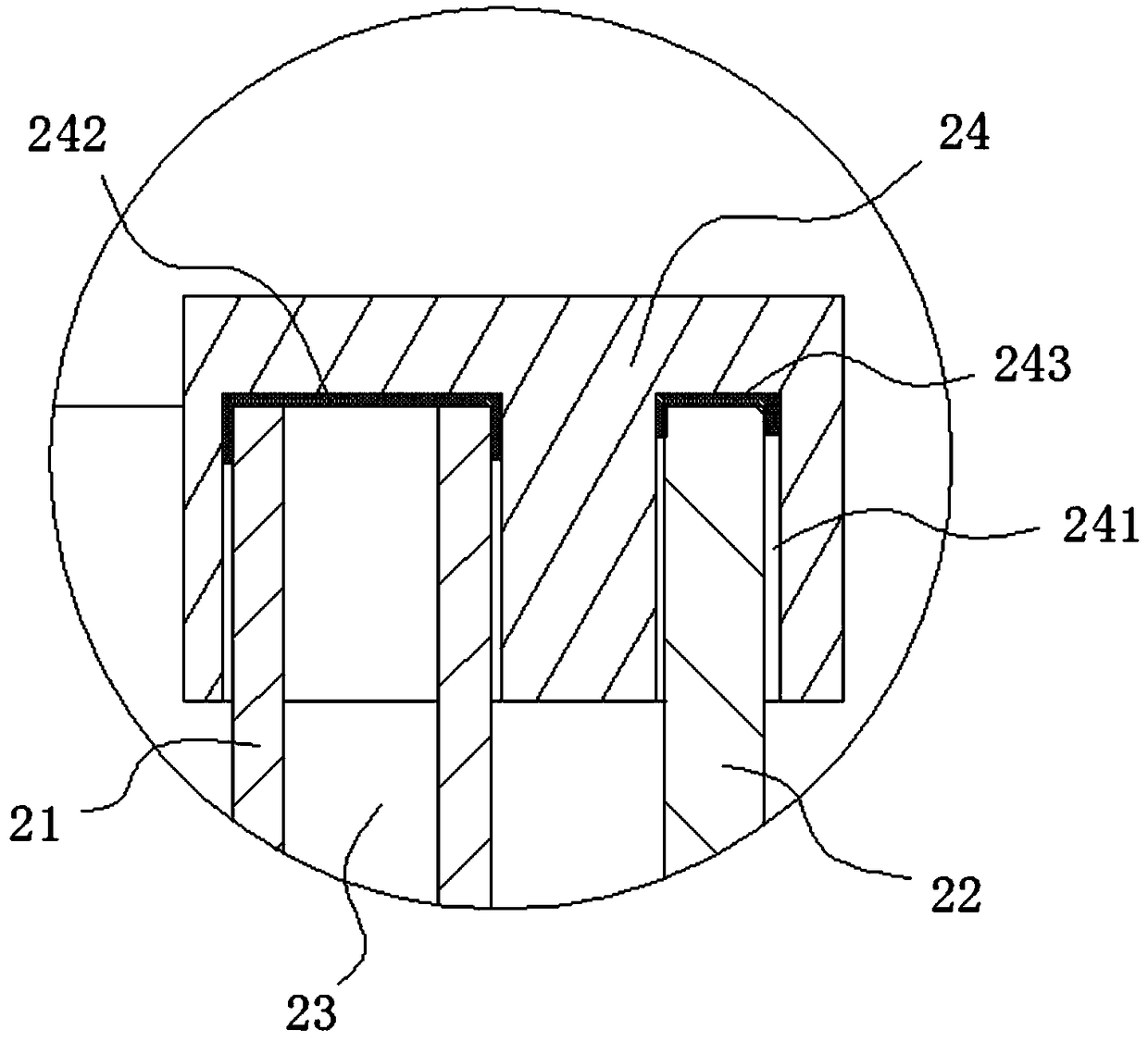

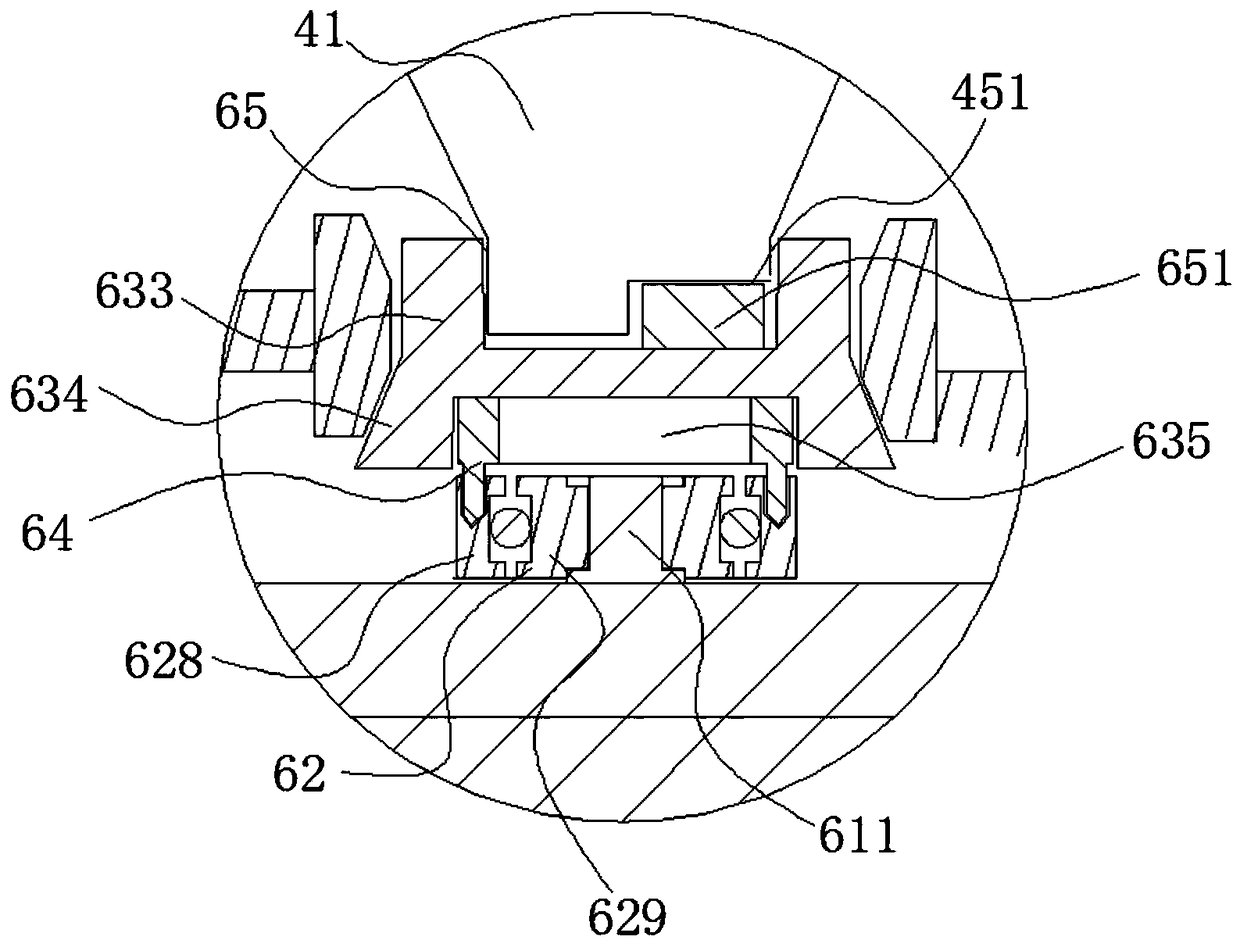

[0018] Such as Figure 1-4 As shown, an efficient ink processing device includes a base 1, a barrel body 2, a driving part 3 and a stirring part 4; the barrel body 2 includes an outer barrel 21 and an inner barrel 22 arranged in the outer barrel 21, and the There is a gap between the inner and outer barrels to form a circle of heating channels 23, which are filled with hot water; the outer barrel 21 is provided with a water inlet pipe 211 and a water outlet pipe 212, and the water inlet pipe 211 and the water outlet pipe 212 communicate with each other, and then realize the water circulation in the heating channel 23; the outlet pipe 212 is covered with a metal casing 213, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com