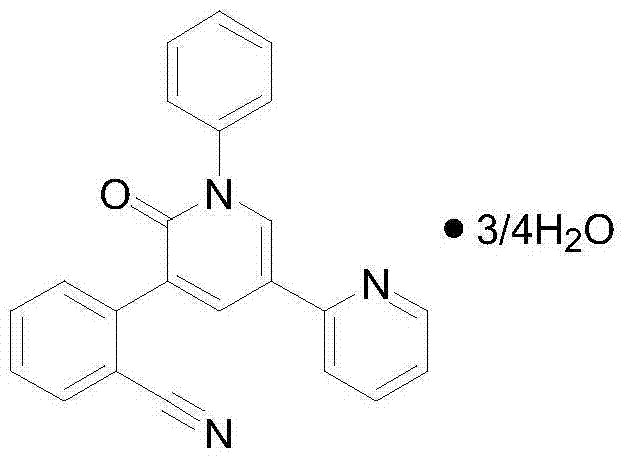

Perampanel freeze-dried oral disintegrating tablet and preparation method thereof

An orally disintegrating tablet and freeze-drying technology, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems affecting patients' emotions, esophageal discomfort, and difficulties in taking coated tablets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

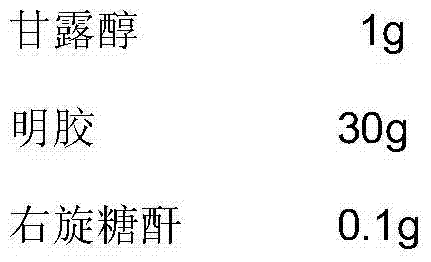

[0047] The dosage of each component in the preparation:

[0048]

[0049]

[0050] Add the skeleton proppant mannitol, binder gelatin, and freeze-drying protective agent dextran into water to fully dissolve, add perampanel, stir evenly, and dissolve to 0.2L;

[0051] Draw the liquid medicine and inject 0.2ml into each blister model;

[0052] Place the mold in a -50°C environment for quick freezing;

[0053] Put the solid liquid medicine into the freeze-drying box, vacuumize at -30℃ low temperature environment, and keep the vacuum for 3 hours at a vacuum degree of 10-20Pa;

[0054] Raise the temperature to -10℃~-15℃ and keep it for 3 hours;

[0055] Raise the temperature to 5°C-15°C and keep it for 1 hour;

[0056] Raise the temperature to 20°C-30°C and keep it for 1 hour;

[0057] Out of the box, laminating, cutting, and printing the batch number.

Embodiment 2

[0059] The dosage of each component in the preparation:

[0060]

[0061] Add the skeleton proppant mannitol, binder gelatin, freeze-drying protective agent dextran, and flavoring agent aspartame into water to fully dissolve, add perampanel, stir well, and dissolve to 0.2L;

[0062] Draw the liquid medicine and inject 0.2ml into each blister model;

[0063] Place the mold in a -40°C environment for quick freezing;

[0064] Put the solid liquid medicine into the freeze-drying box, vacuumize at -20 ℃ low temperature environment, vacuum degree 10-20Pa, keep for 3 hours;

[0065] Raise the temperature to -10℃~-15℃ and keep it for 4 hours;

[0066] Raise the temperature to 5°C-15°C and keep it for 2 hours;

[0067] Raise the temperature to 20°C-30°C and keep it for 2 hours;

[0068] Out of the box, laminating, cutting, and printing the batch number.

Embodiment 3

[0070] The dosage of each component in the preparation:

[0071]

[0072] Add the skeleton proppant mannitol, binder hydrolyzed gelatin, freeze-drying protective agent dextran, and flavoring agent sucralose into water to fully dissolve, add perampanel, stir evenly, and settle to 0.2L;

[0073] Draw the liquid medicine and inject 0.2ml into each blister model;

[0074] Place the mold in a -60°C environment for quick freezing;

[0075] Put the solid liquid medicine into the freeze-drying box, vacuumize at -50℃ low temperature environment, the vacuum degree is 10-20Pa, keep for 3 hours;

[0076] Raise the temperature to -10℃~-15℃ and keep it for 4 hours;

[0077] Raise the temperature to 5°C-15°C and keep it for 1 hour;

[0078] Raise the temperature to 20°C-30°C and keep it for 2 hours;

[0079] Out of the box, laminating, cutting, and printing the batch number.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com