Collision shunt combustion chamber of diesel engine

A combustion chamber and diesel engine technology, which is applied in combustion engines, mechanical equipment, machines/engines, etc., can solve the problems of low utilization rate of the headspace space of combustion chambers, reduce NOx emissions, increase mixing rate and space area, and improve economy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

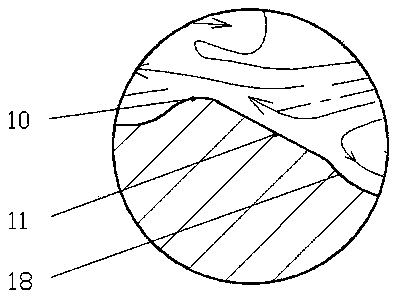

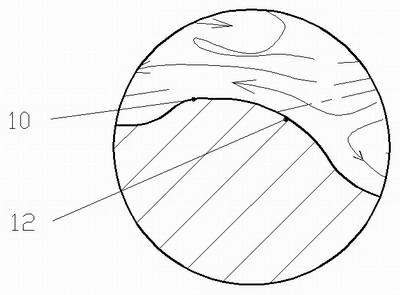

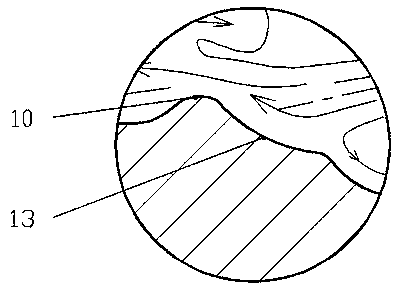

[0034] figure 1 A schematic diagram of the structure of the collision-split combustor of a diesel engine is shown. In the figure, the fuel injector 5 of the diesel engine colliding with the split combustion chamber sprays the high-pressure fuel into the combustion chamber 4 composed of the cylinder head 1, the cylinder liner 2 and the piston 3 in the form of multiple oil beams. Gap height H, adjust throat diameter D 1 And set the collision ring zone, the combustion chamber 4 is divided into two sections of the combustion chamber head gap 7 and the combustion chamber central part 8, the diameter D of the combustion chamber head gap 7 2 is the cylinder diameter. The mist oil beam 6 sprayed from the injector 5 is sprayed onto the collision zone 9, a part of the oil beam is rebounded for secondary atomization, and a part of the oil beam flows along the spray collision zone 9 to the top clearance part 7 and the combustion chamber respectively. The central part of the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com