Mixing process production device for construction

A technology for production equipment and construction, which is applied in the field of production equipment in the construction mixing process, can solve problems such as incomplete mixing of building materials and damage to devices, and achieve the effects of avoiding blind spots in mixing, preventing impact damage, and increasing the mixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

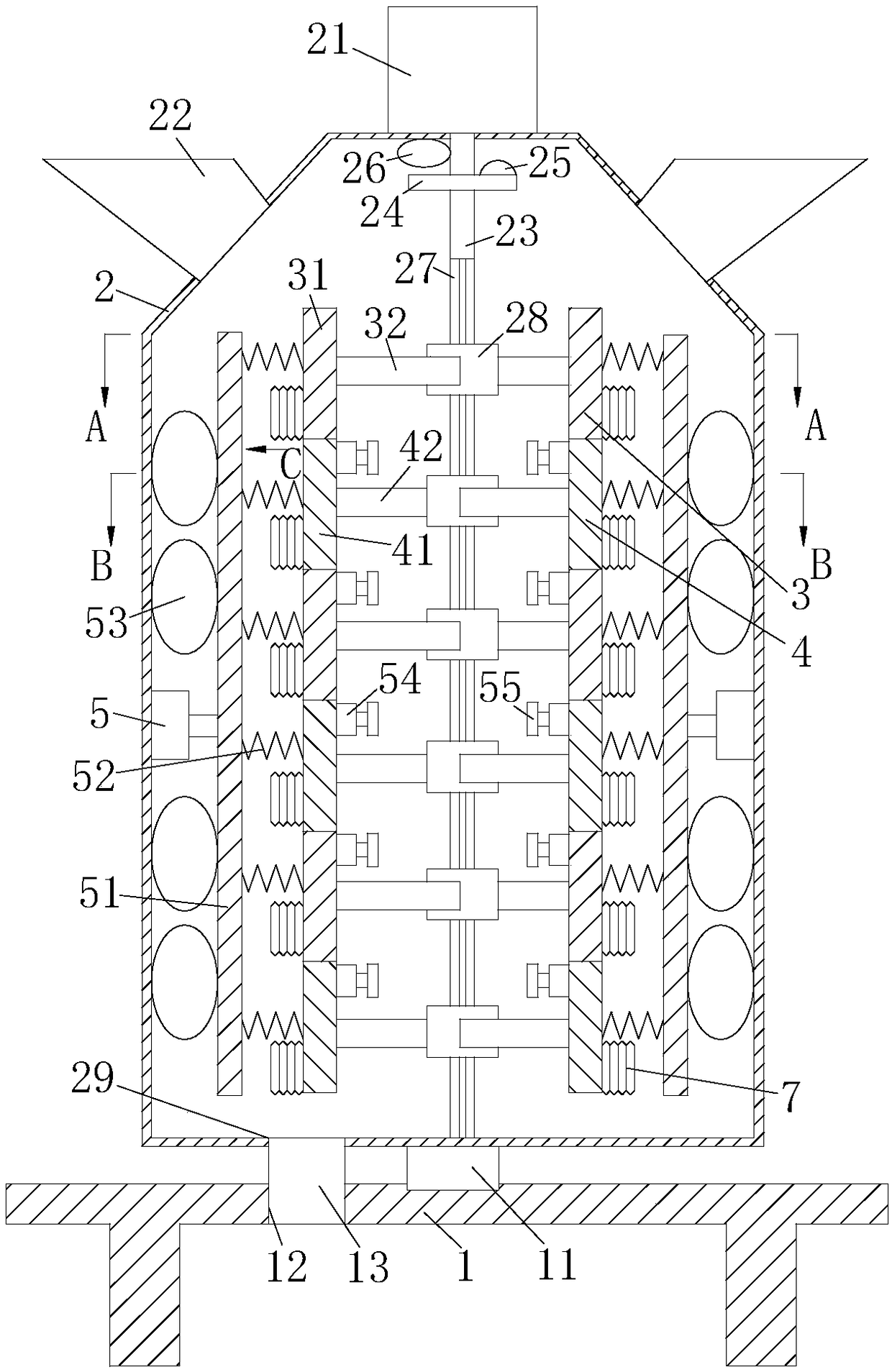

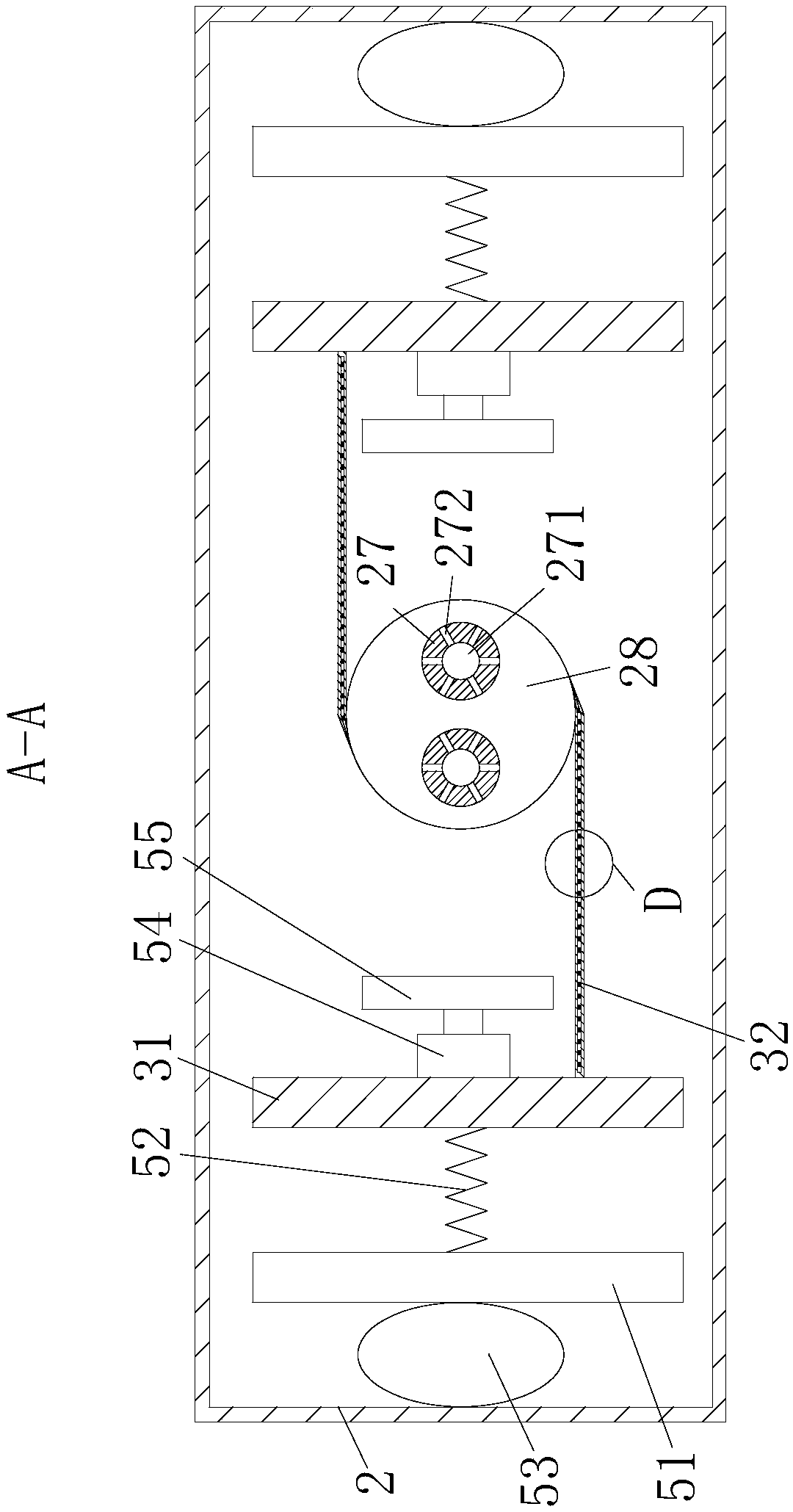

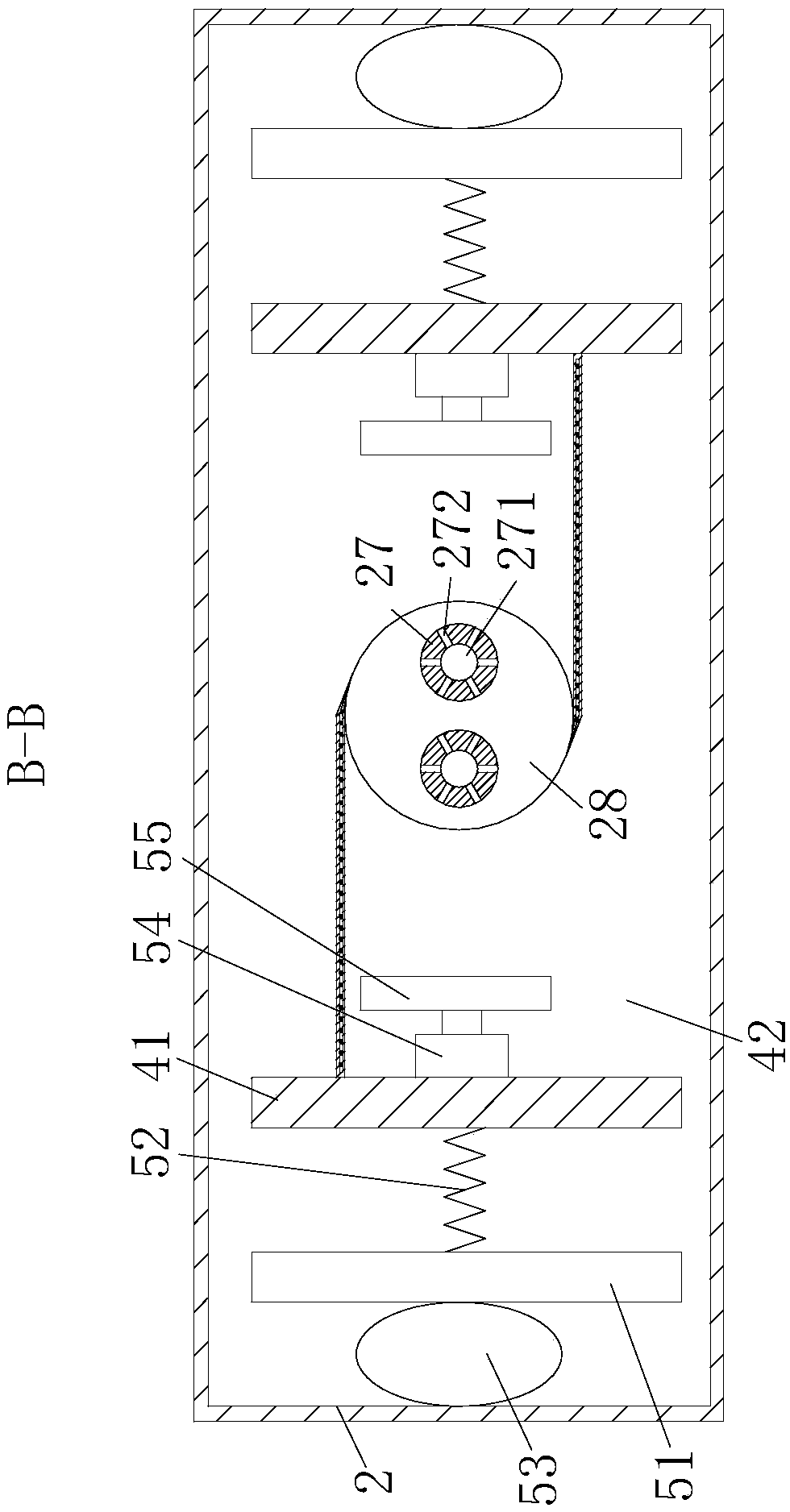

[0025] As an embodiment of the present invention, it is characterized in that: a second air bag 53 is evenly arranged between the third push plate 51 and the inner wall of the frame body 2; the first push plate 31 and the second push plate 41 are close to the elastic One side of bar 27 is all connected with second air cylinder 54; Said second air cylinder 54 is arranged horizontally, and second air cylinder 54 communicates with second air bag 53; Four push pedals 55; the length of the fourth push pedal 55 is less than the shortest distance between two adjacent discs 28; during work, the third push pedal 51 reciprocates left and right, extruding and relaxing the second air bag 53, so that The protruding end of the second cylinder 54 stretches out and shrinks, drives the fourth push plate 55 to reciprocate, and can mix the building materials between the discs 28, avoid mixing blind spots, and make the mixing more fully.

[0026] As an embodiment of the present invention, the ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com