Battery negative electrode material mixing device with cyclic grinding equipment

A battery negative electrode, cyclic pulverization technology, applied in mixers with rotary stirring devices, mixers, transportation and packaging, etc., can solve problems to be improved, and achieve the effects of simple structure, improved production rate, and improved rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

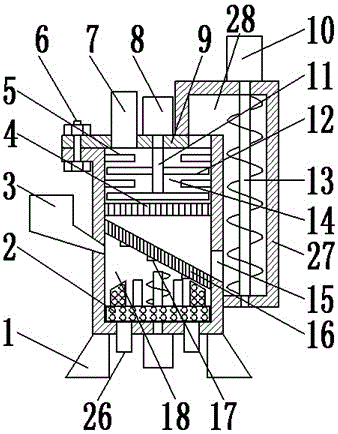

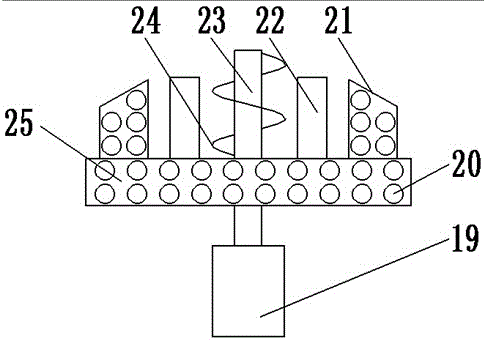

[0019] see Figure 1-2 , a battery negative electrode material mixing device with circulating crushing equipment, including a mixing chamber 18; a discharge pipe 26 is provided at the bottom of the mixing chamber 18; a stirring and mixing device 2 is provided inside the mixing chamber 18, and an inclined plate is provided at the top 16. The left side is provided with an additive inlet pipe 3, the right side is provided with a discharge port 15, and the bottom is provided with a base 1 for mixing materials; the base 1 is provided in multiples, and is evenly arranged in the mixing chamber 18 The bottom of the bottom is used to support the device, and can ensure the stability of the device; the discharge pipe 26 is provided with two, and is symmetrically arranged on the left and right sides of the stirring motor 19 at the bottom, and is used to discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com