Circular spout bed equipped with circular multi-nozzle ventilation mechanism

A multi-nozzle, spouted bed technology, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve the problems of difficult separate control of the air volume of the air supply pipe, uneven air supply in the bed, and practical operation difficulties, etc., to achieve Enhance gas-solid heat transfer and particle mixing rate, compact structure, and prolong the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

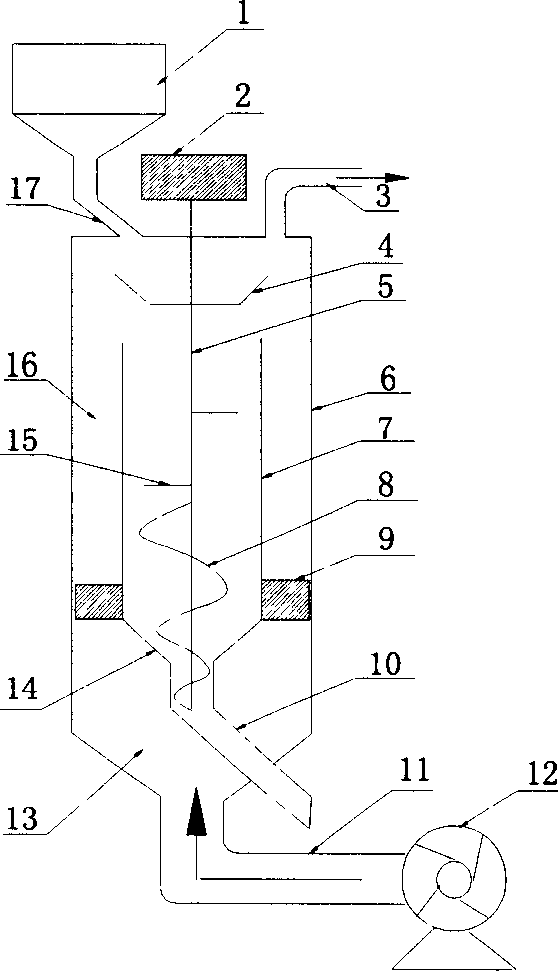

[0037] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

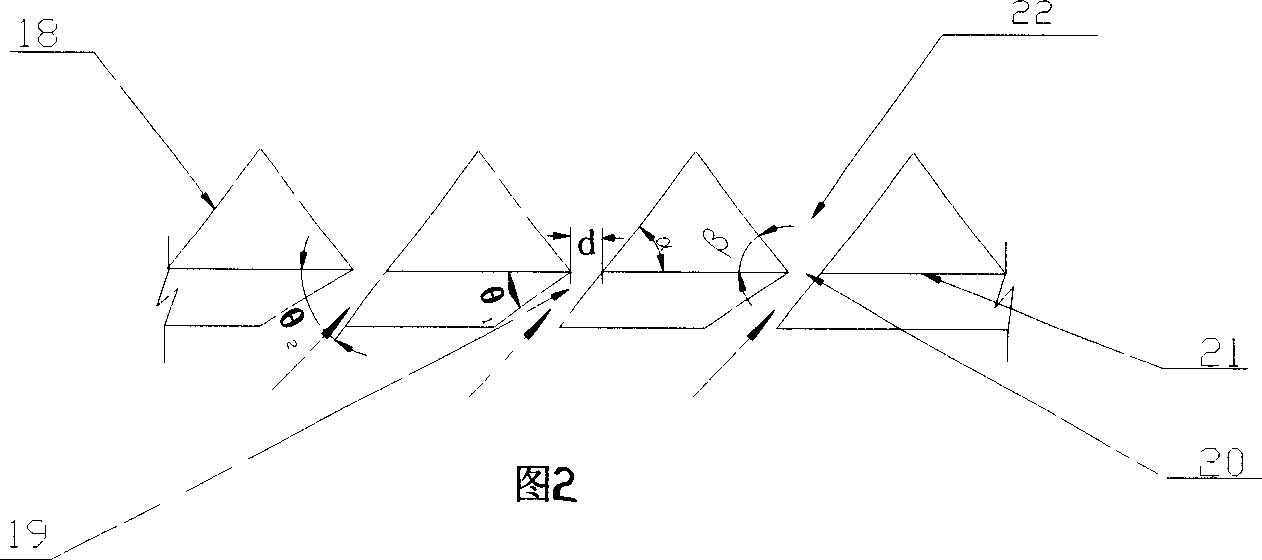

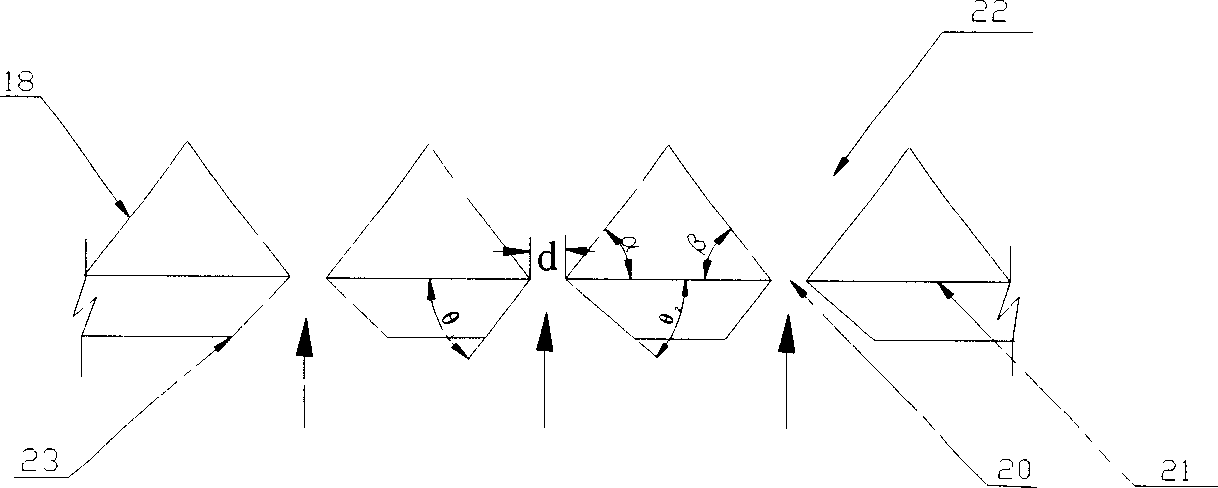

[0038] The annular spouted bed structure of the present invention is as follows figure 1 As shown, it is mainly composed of an annular space 16, an air distribution mechanism 9, a rotating cone distributor 4, a pressure stabilized air chamber 13, a screw discharger 8, a feeder 1, a discharge pipe 10, and the like. The outer cylinder 6 and the inner cylinder 7 are two concentric vertical cylinders centered on the rotating shaft 5, the diameter of the outer cylinder 6 is 200-2800 mm, and the diameter of the inner cylinder 7 is 100-2000 mm. A transition cone 14 is provided at the lower part of the inner cylinder 7 , and the bottom of the transition cone 14 is connected with the discharge pipe 10 . The outer cylinder 6 and the inner cylinder 7 form an annular space 16, a unique multi-spout air distribution mechanism 9 is arranged at the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com