Method and device for separate oxidation and cyclone purification of organic waste gas

A technology of organic waste gas and purification device, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of difficult cultivation of microorganisms, large equipment investment, and limited processing capacity, so as to protect the ring-shaped ultraviolet lamp and improve the reaction rate. Speed, the effect of increasing the contact rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

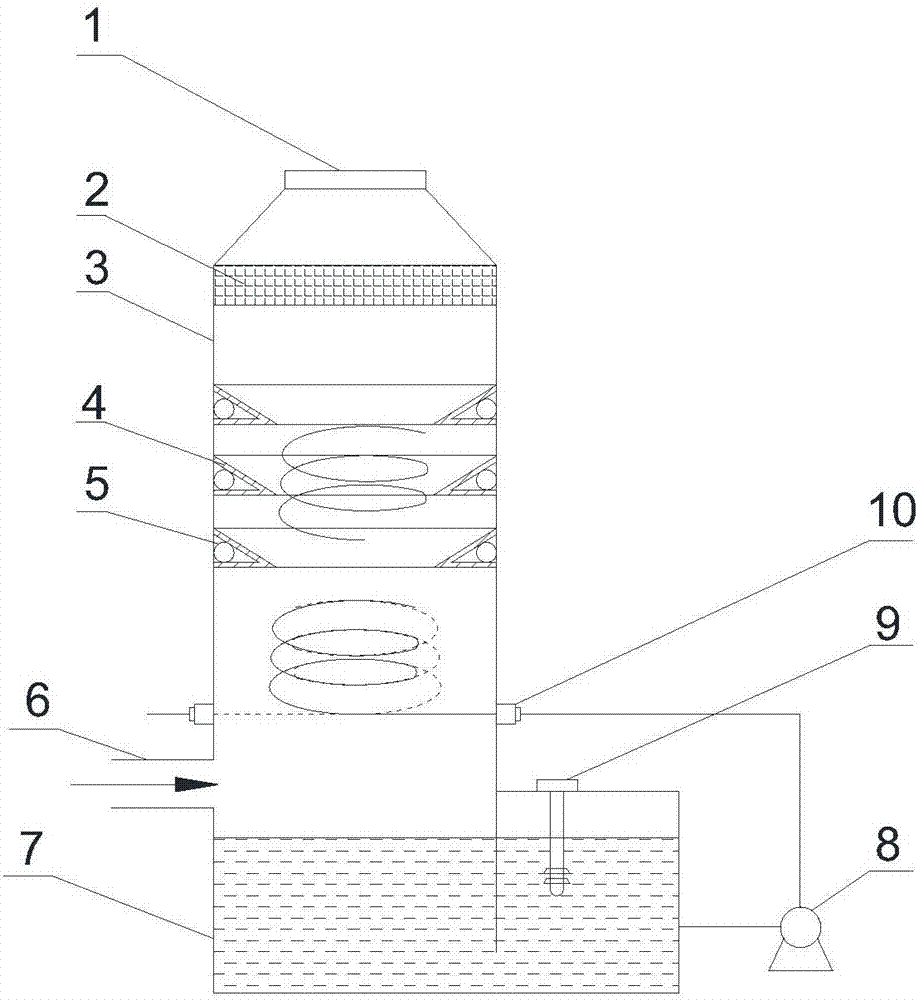

[0041] Such as Figures 1 to 3 shown. The invention discloses a swirl purification device for zonal oxidation of organic waste gas, which comprises a swirl purification tower 3 and a catalytic absorbent recirculation system arranged at the bottom of the swirl purification tower 3;

[0042] The swirling flow purification tower 3 is arranged sequentially from bottom to top: catalytic absorber swirl atomization layer, ultraviolet zonal oxidation layer, waste gas absorption and demisting layer;

[0043] The catalytic absorbent recirculation system is used to provide the nano-titanium dioxide atomization liquid required for atomization to the catalytic absorbent cyclone atomization layer, and recover the nano-titanium dioxide slurry that falls back to the catalytic absorbent recirculation system under the action of gravity.

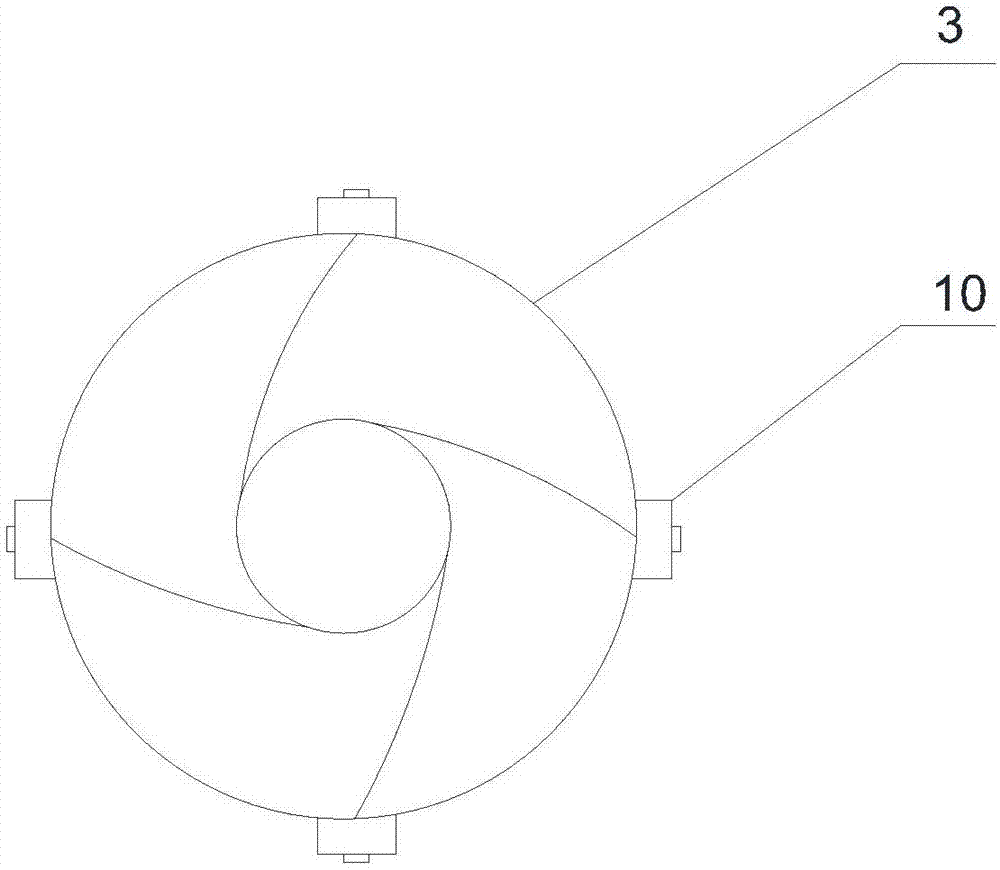

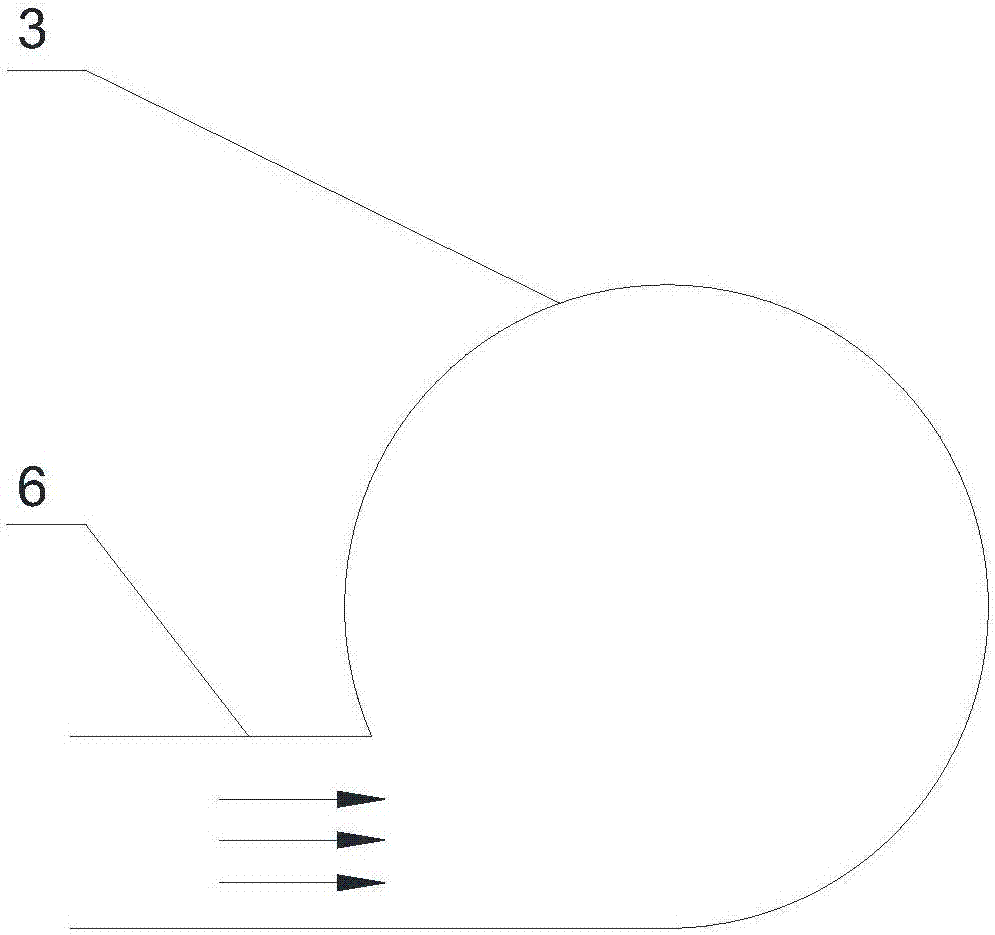

[0044] The swirl atomization layer of the catalytic absorber is: a swirl atomizer 10 arranged in an array and tangentially arranged above the organic waste g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com