System for preparing biomass pellet fuel by taking straws and black liquor of paper mills as raw materials

A technology for the preparation of biomass particles and fuels, applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of single composition of biomass raw materials and difficult treatment of black liquor in paper mills, so as to reduce energy loss, heat consumption and metal waste. Energy consumption and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

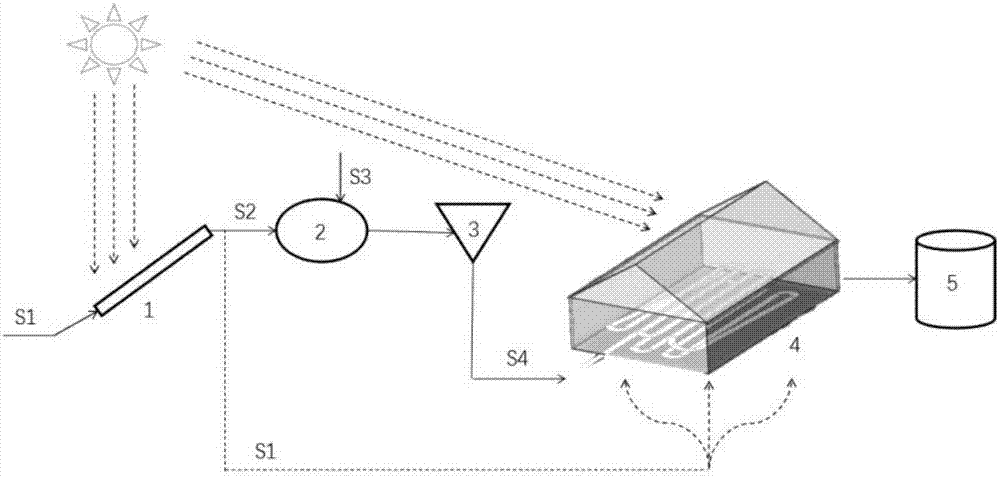

[0023] figure 1 It is a schematic structural diagram of a system for efficiently preparing biomass pellet fuel using straw and paper mill black liquor as raw materials provided by the present invention. The system includes a flat-plate solar collector 1, a straw-black liquor mixing dryer 2, and a pulverizer 3 , greenhouse-heat-collecting solar drying room 4, biomass molding machine 5, wherein the heat collected by the flat-plate solar collector 1 is used to increase the temperature of the air S1 entering the collector, so that the air S1 reaches the time when the biomass is dried In addition, the heated air S1 is divided into two parts, and one part uses the blower to carry the wheat straw into the straw-black liquor mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com