Incinerator grate with transversely and longitudinally staggered head bosses

A dislocation arrangement, incinerator technology, applied in incinerators, combustion methods, combustion types and other directions, can solve the problem of insignificant garbage dispersing effect, and achieve the effect of being conducive to rapid combustion, shortening drying time, and aggravating instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

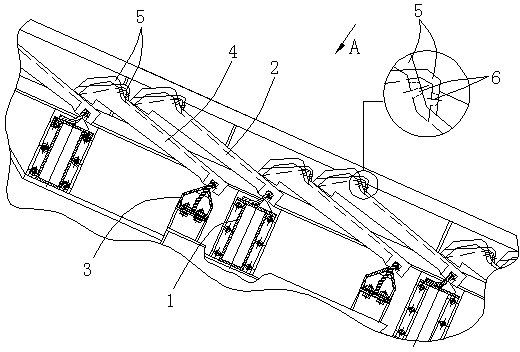

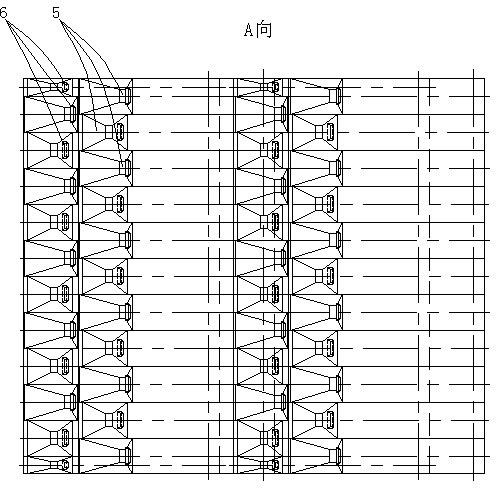

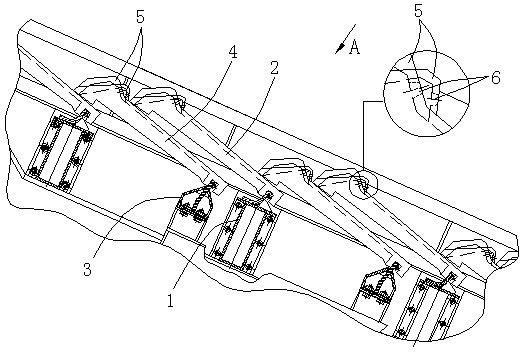

[0022] Such as figure 1 , figure 2 As shown, the fixed beam 1 installed on the side beam passes through the slot at the end of the same row of fixed grate pieces 2 to form a fixed fire grate plate, and the movable beam 3 installed on the pull rod passes through the slot at the end of the same row of movable grate pieces 4 grooves to form a movable grate plate, and the layout of the side beams and tie rods is the same as that of the prior art, and will not be repeated here. The movable grate boards overlap with the fixed grate boards front and back, and are arranged alternately to form a fire grate.

[0023] From figure 1 , figure 2 It can be seen from the figure that a head boss 5 is integrally formed on the front end of the upper surface of each grate piece, and the head boss 5 is in the shape of a forward wedge-shaped quadrangular truss, and the heads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com