Packing material combination plate element unsaturated evaporative radiator

A combined plate and radiator technology, applied in the field of unsaturated evaporative radiators, can solve the problems of unfavorable heat transfer of unsaturated evaporative heat transfer, reduced heat transfer efficiency, corrosion and damage of tube walls, etc., and achieves increased evaporation area, reduced wind resistance, and improved The effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

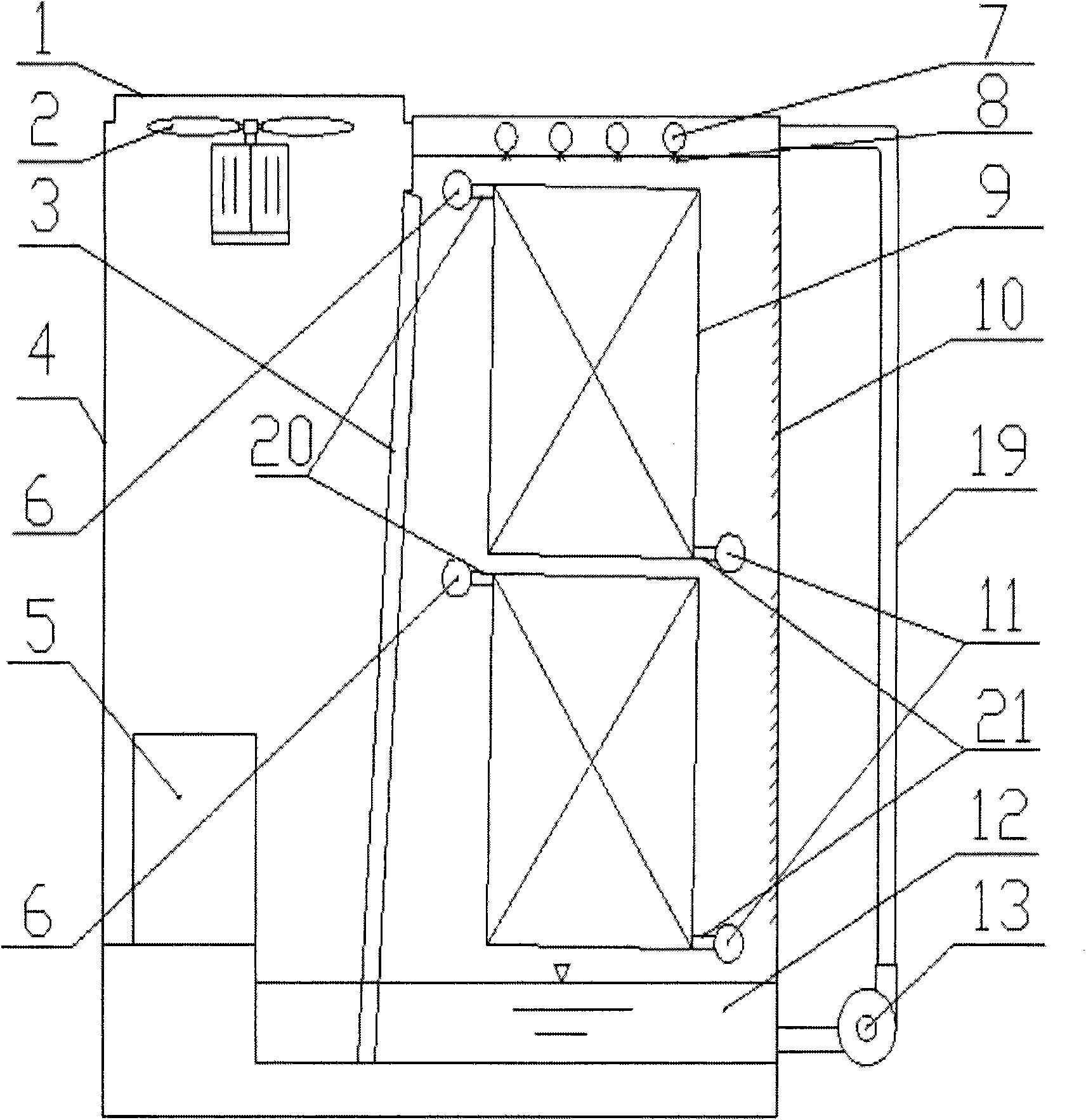

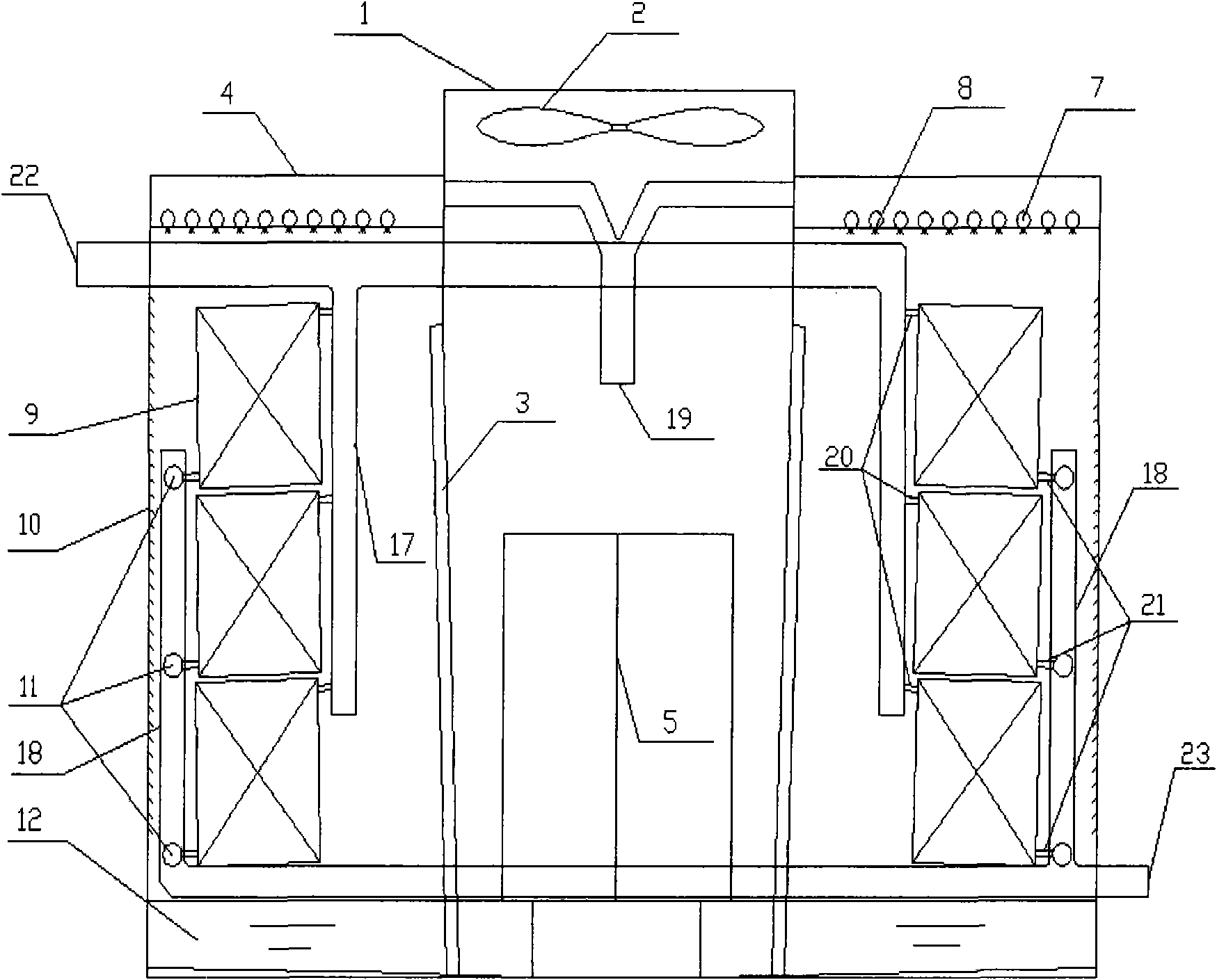

[0024] Embodiments of the present invention are as follows: for the condenser in the refrigeration system of a certain food freezing plant, the refrigerant is R22, the heat dissipation is 1335KW, and the structure is image 3 Form, the weight is about 3370kg in the non-operating state, and the length, width and height are 2400×3500×3000mm, which can save about 46.5% of the floor space compared with the same heat load tubular products.

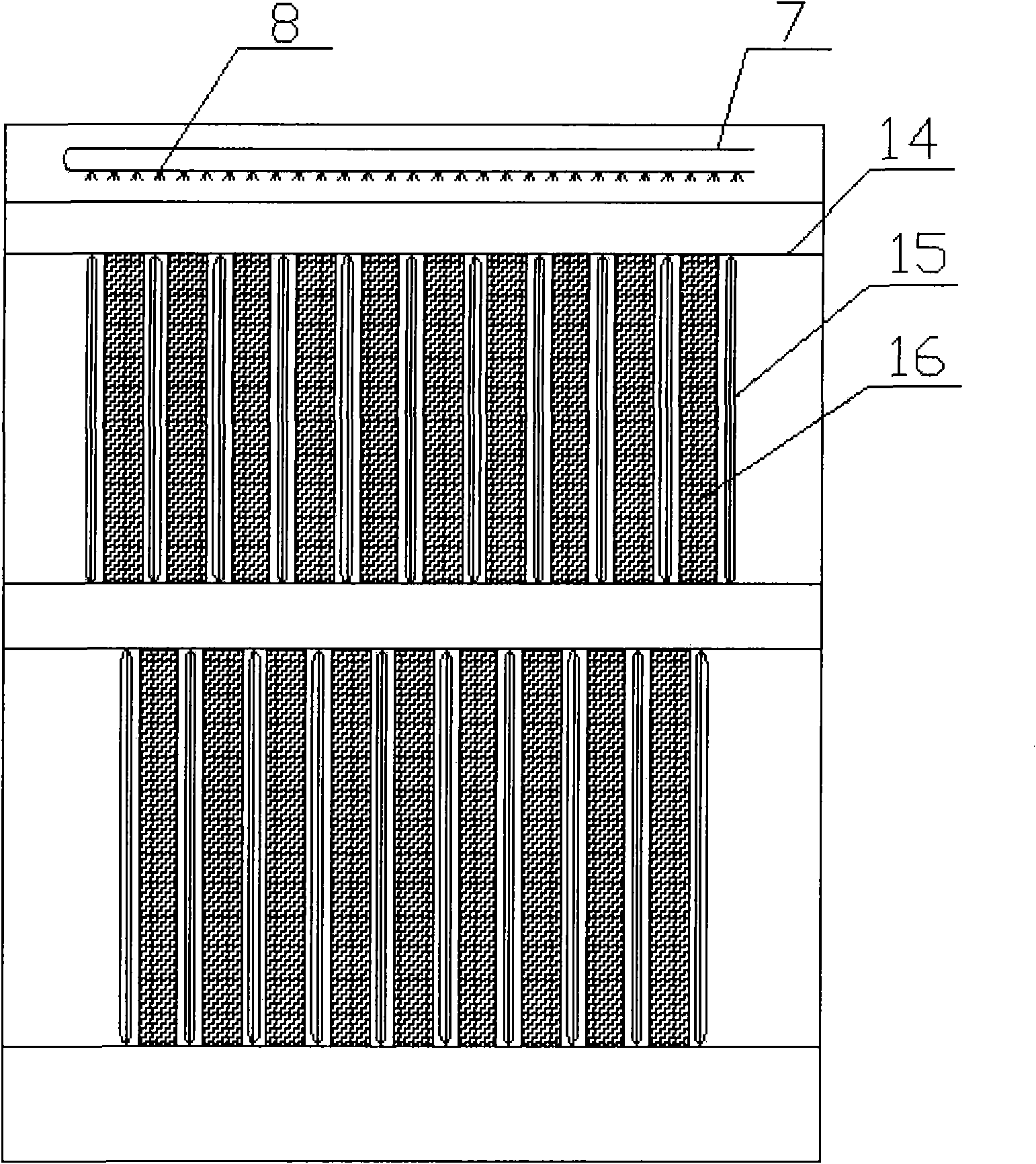

[0025] The heat exchange plate tube 15 of the condenser is made of hot-dip galvanized carbon steel plate, and 3 pieces of PPEC packing 16 are installed between two adjacent plates. There are 72 pieces of plate tubes 15 included in the combined plate unit 9, and the weight of the product is reduced by about 53% compared with the tube type products with the same heat load.

[0026] When the product is running, the refrigerant enters the medium inlet main pipe 17 through the medium inlet main pipe connection pipe 22, and then enters the medium inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com