Filter device for laboratory

A filtration device and laboratory technology, applied in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of slow filtration, low efficiency, time-consuming filtration, etc., to speed up the filtration rate , the effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

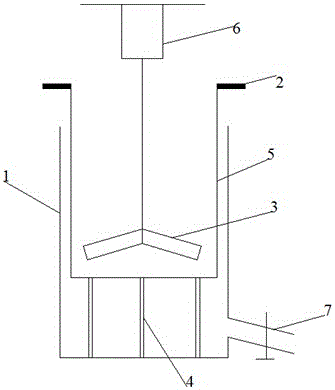

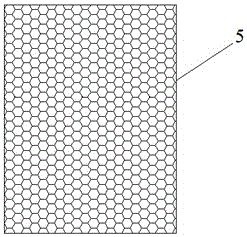

[0017] In this example, if figure 1 with figure 2 As shown, a filter device for laboratory use includes a filter tank 5 with an open top, and the side and bottom surfaces of the filter tank 5 are evenly provided with filter holes, and the top of the filter tank 5 opening is provided with a shaft vertically The lower motor 6 is connected to the agitator 3 with a rotating shaft, and the stirring paddle of the agitator 3 is in the filter tank 5 .

[0018] The working process of the present invention is: earlier the bottom of filter pool 5 is wetted, and filter paper is placed on the bottom of filter pool 5 and fully covers the bottom of filter pool 5, and is placed a container for containing filtrate directly below filter pool 5. Containers, solutions often have corrosiveness, according to the difference of the solution, use containers of different materials to hold the filtered solution, then pour the fully reacted solution into the filter pool 5, start the motor 6, in order t...

Embodiment 2

[0020] In this embodiment, a liquid holding pool 1 is further added on the basis of the above-described embodiments. The outside of the filter pool 5 is provided with a liquid holding pool 1 for adorning filtrate. In the present invention, adding a liquid holding pool 1 can eliminate the need to The liquid holding pool 1 is placed separately, which reduces labor and saves time. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0022] In this embodiment, a support column 4 is further added on the basis of the above-mentioned embodiment. A support column 4 for supporting the filter tank 5 is provided between the bottom of the filter tank 5 and the bottom of the liquid holding tank 1. The function of the support column 4 is It is not to allow the filter tank 5 to be soaked in the solution of the liquid holding tank 1, which will cause difficulty in filtration. If there is no supporting column 4 after the filtration is completed, there will be negative pressure between the filter tank 5 and the liquid holding tank 1, which is difficult to separate. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com