Novel 900-t/d high-heat-value domestic garbage incinerator

A domestic waste incineration and high calorific value technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as uneven temperature distribution on both sides of the flue, affecting the service life of the furnace wall, and overheating of the front arch wall. It is beneficial to the secondary combustion, improves the comprehensive heat utilization rate, and has the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

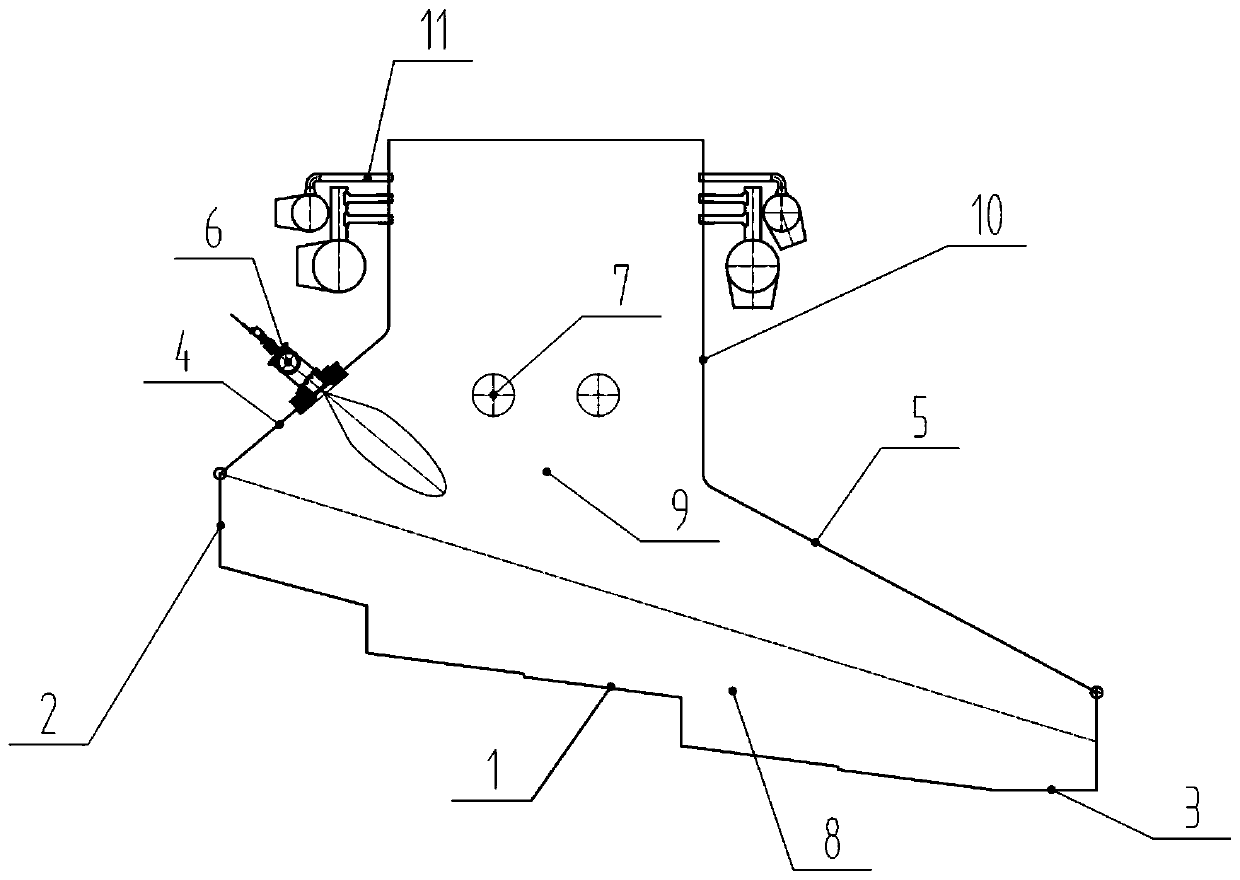

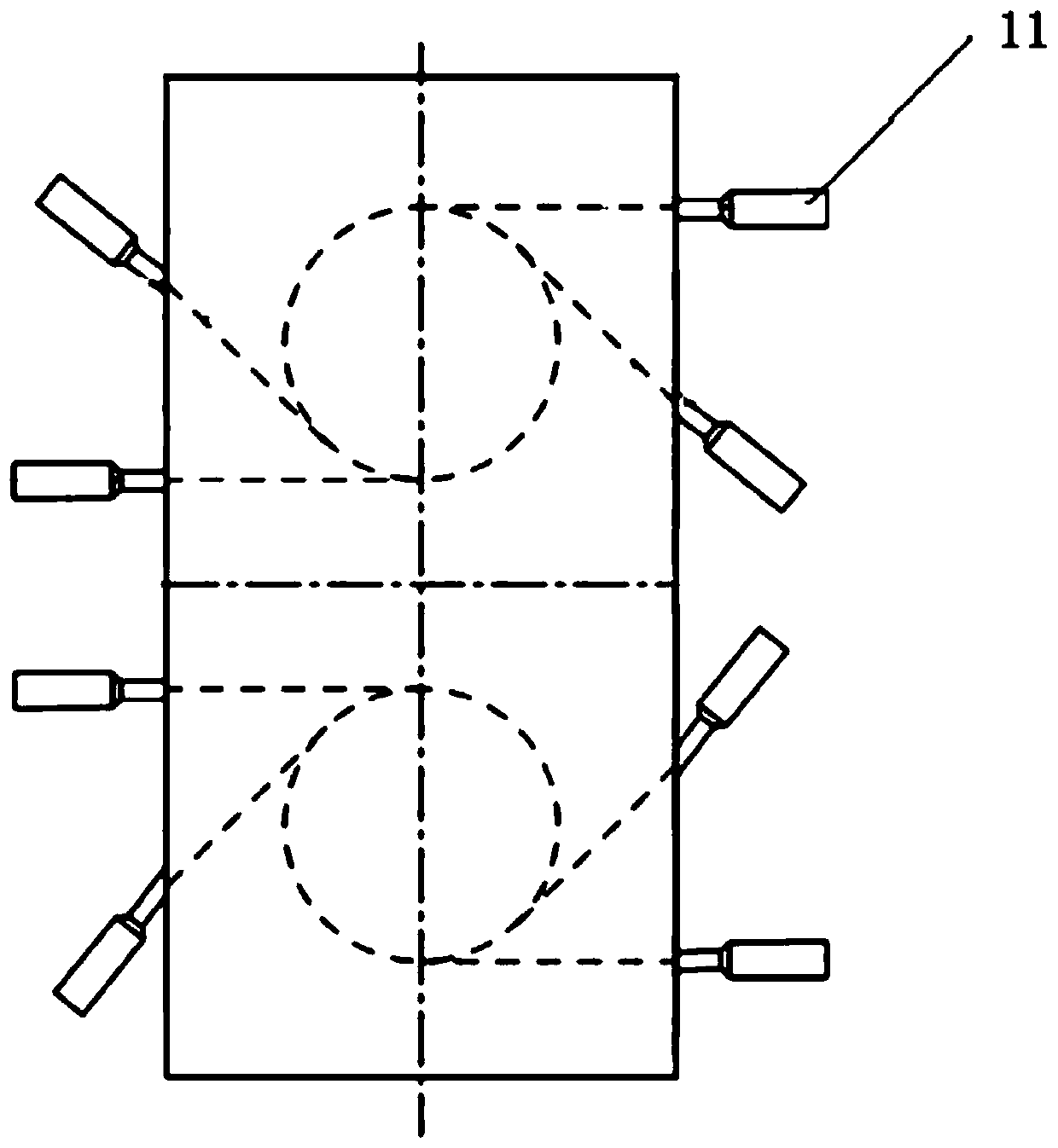

[0034] Furnace structure such as figure 1 As shown, the width of the hearth is 5.6 meters, the fire grate 1 is located at the bottom of the hearth, the front end is provided with a feed port 2, the tail end is provided with a slag discharge port 3, and both sides of the fire grate are refractory furnace walls 8. Two ignition burners 6 are arranged on the front arch 4 of the furnace wall on the upper part of the furnace, and an auxiliary burner 7 is respectively installed on the left and right side walls 9 . The entrance of the flue is located in the front middle of the furnace, the water wall is arranged around the flue 10, and extends to the middle of the furnace wall along with the front arch 4, the rear arch 5 and the side wall 9, and the lower part of the flue is provided with the entrance of the secondary air pipe 11, see figure 2 The diameter of the secondary wind shear circle is 3 meters. The angle α between the front buttress wall surface of the furnace and the horiz...

Embodiment 2

[0036] Same as embodiment 1, only the furnace width is 4.5 meters, the secondary wind cut circle diameter is 2.5 meters, the angle α between the wall of the front arch (4) of the furnace and the horizontal plane is 30 °, the angle between the wall of the rear arch of the furnace 5 and the horizontal plane β is 20°, the fire grate (1) is divided into four levels, and there is no water cooling wall at the front arch (4), rear arch (5) and side wall (9).

Embodiment 3

[0038] Same as embodiment 1, only the width of the hearth is set to 8 meters, the diameter of the secondary wind shear circle is 3.5 meters, the angle α between the 4 walls of the front arch of the hearth and the horizontal plane is 60°, and the angle β between the walls of the back arch 5 of the fire hearth and the horizontal plane is 50°, and there are three ignition burners (6).

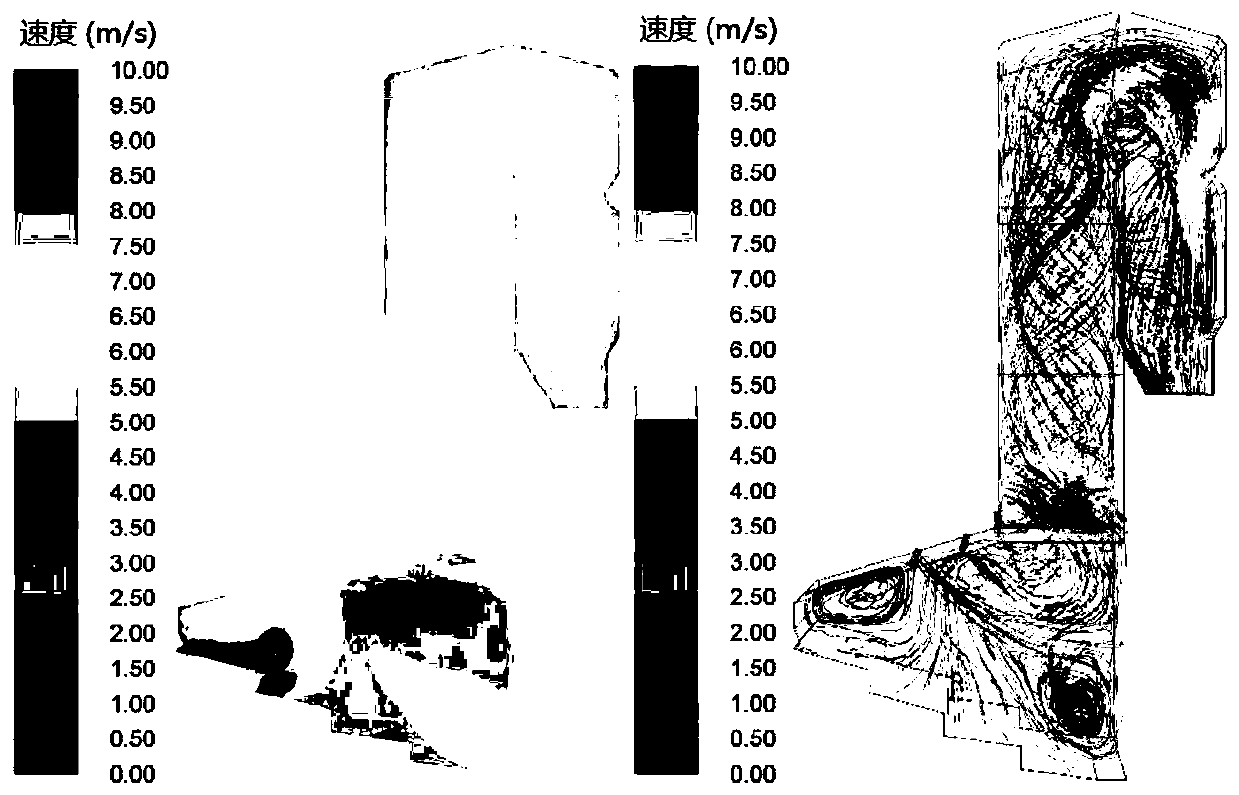

[0039] There is a 750t / d furnace type as attached image 3 As shown, the high temperature area generated by its combustion extends from the grate to the front arch of the furnace, and moves with the airflow to the direction of the flue. The secondary combustion occurs at the junction of the furnace and the flue, the temperature in the flue is low, and the combustion-supporting effect of the secondary air is limited. The temperature near the slag outlet is high, and the heat loss of slag discharge is relatively large. The overall flow velocity and disturbance degree of flue gas in the flue are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com