Vortex broken flow type hydrogen cold box

A technology of fragmented flow and cold hydrogen, which is applied in the petroleum industry, chemical instruments and methods, and hydrocarbon oil treatment, etc., can solve the problems of short residence time, uneven cooling, and insufficient mixing, so as to achieve small kinetic energy loss and increase the contact area. , the effect of reducing the height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

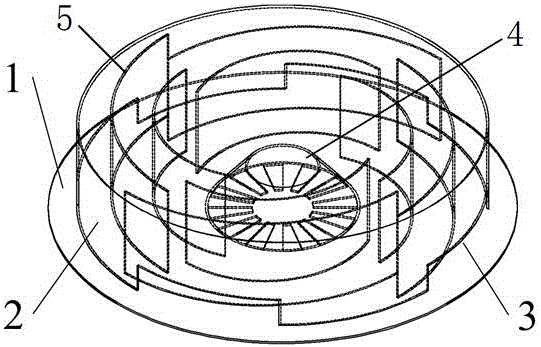

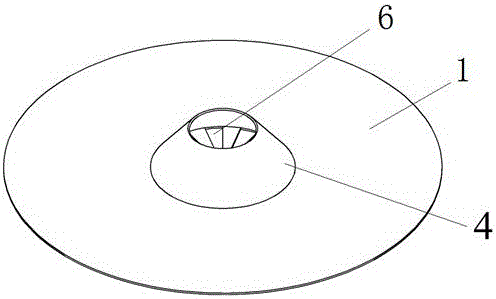

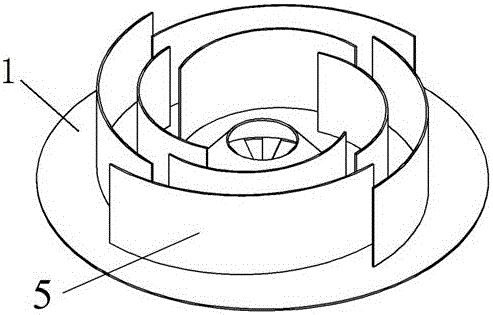

[0029] Such as Figure 1 to Figure 4 The shown one kind of swirling broken flow type cold hydrogen tank is installed in the hydrogenation reactor and is located under the cold hydrogen pipe. An annular gap is formed between the barrels of the mixer, and several rectangular feed inlets 3 are evenly provided on the bottom of the outer wall of the mixing box 2, and a circular platform-shaped overflow tube 4 is installed on the outlet of the gas-liquid mixture in the center of the mixing box 2, and the overflow tube 4 The height of the center is higher than the height of the upper edge of the feed inlet 3, the top of the overflow tube 4 is provided with a gas-liquid inlet, the area of the gas-liquid inlet is smaller than the area of the gas-liquid outlet at the bottom, and the gas-liquid inlet at the top of the overflow tube 4 The area is smaller than the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com