Micro-oil ignition system and method for w-type flame boiler

A micro-oil ignition and flame technology, which is applied in the combustion method, combustion type, burner for burning powder fuel, etc., can solve the problems of low fuel saving rate, system explosion, complicated operation, etc., to ensure safety and reliability. , The effect of improving fuel saving rate and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawings and examples.

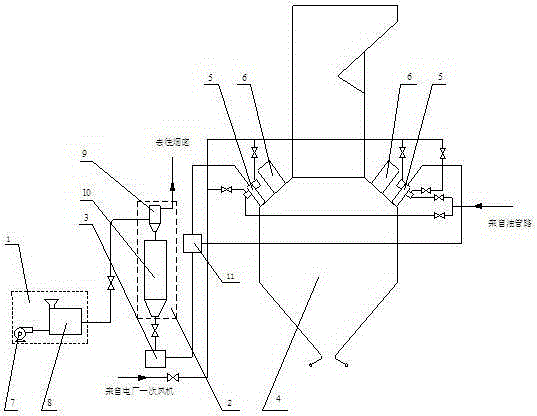

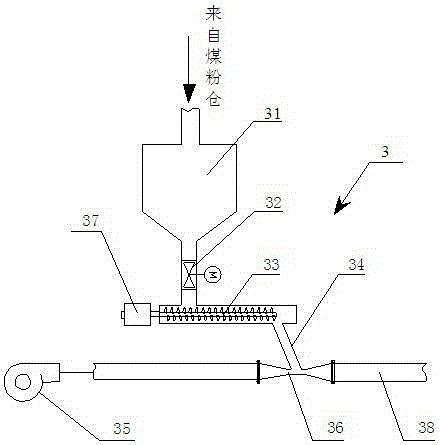

[0023] Such as figure 1 with figure 2 As shown, the micro-oil ignition system suitable for W-type flame boilers includes pulverized coal preparation system 1, pulverized coal storage system 2, pulverized coal delivery system 3, boiler body 4, pulverized coal burner for micro-oil ignition pulverized coal, and primary burner 6 , pulverized coal distributor 11, pulverized coal preparation system 1 includes blower 7 and coal mill 8, pulverized coal storage system 2 includes bag filter 9 and pulverized coal bin 10, pulverized coal conveying system 3 includes intermediate pulverized bin 31, Electric valve 32, powder conveying auger 33, blanking pipe 34, Roots blower 35, air powder mixer 36, powder conveying auger motor 37, primary air supply pipe 38, blower 7, coal mill 8, bag type Dust collector 9, pulverized coal bin 10, pulverized coal conveying system 3, pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com