Central cavity stable fire tangential combustion chamber

A combustion chamber and cavity technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problem of affecting combustion efficiency and outlet temperature distribution, the tangential momentum of the compressor outlet airflow is not well utilized, and the length is shortened, etc. problem, to achieve the effect of long residence time, compact structure and reduced length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

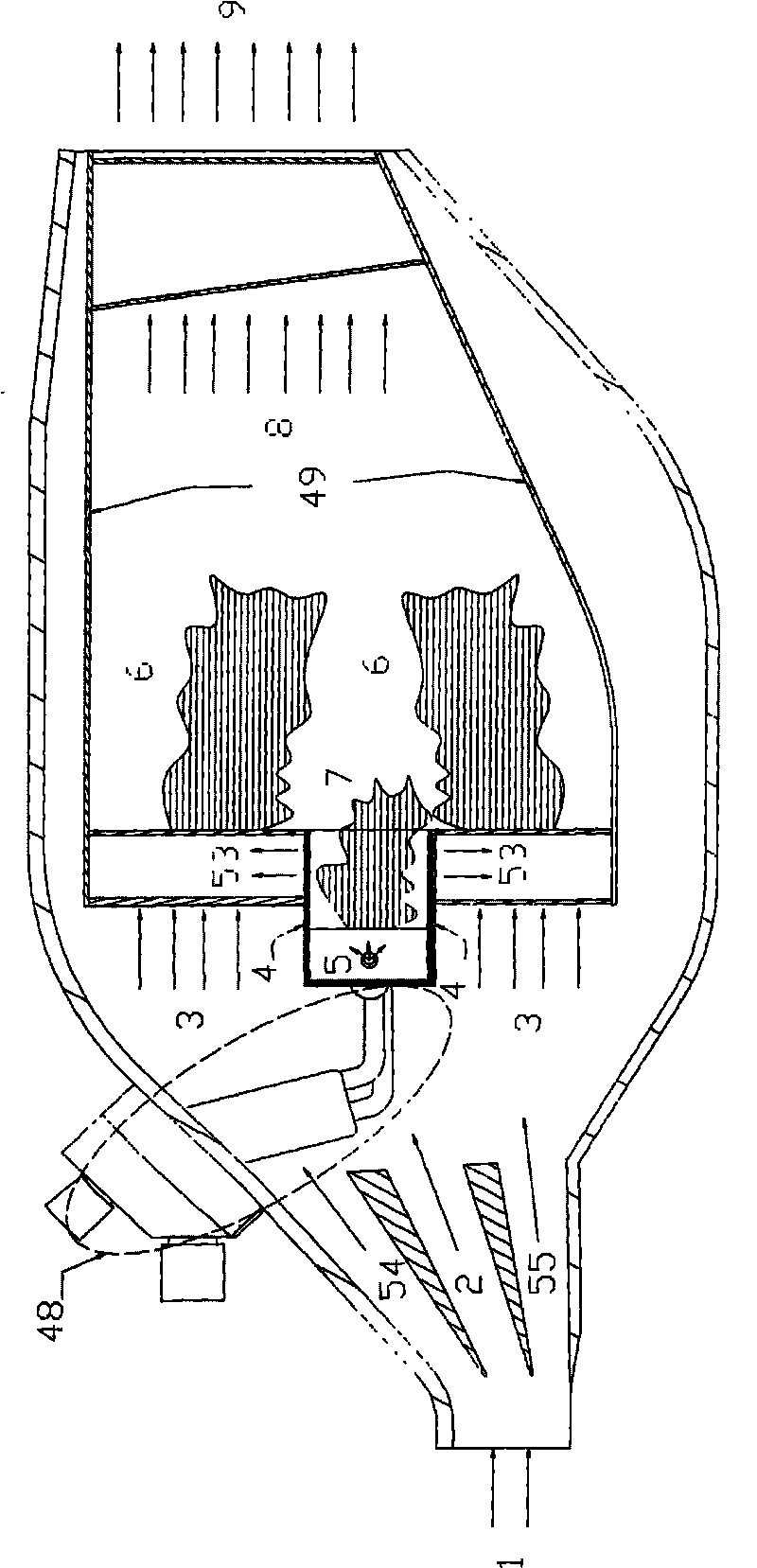

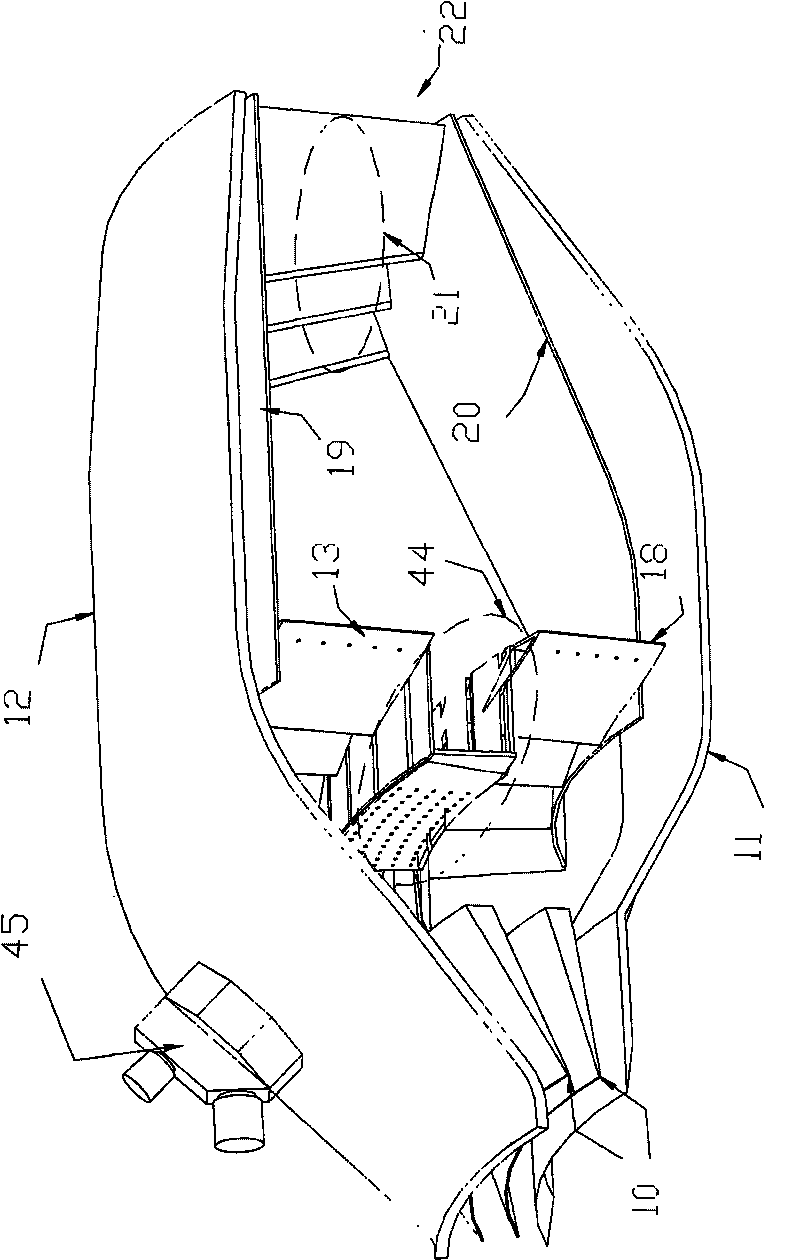

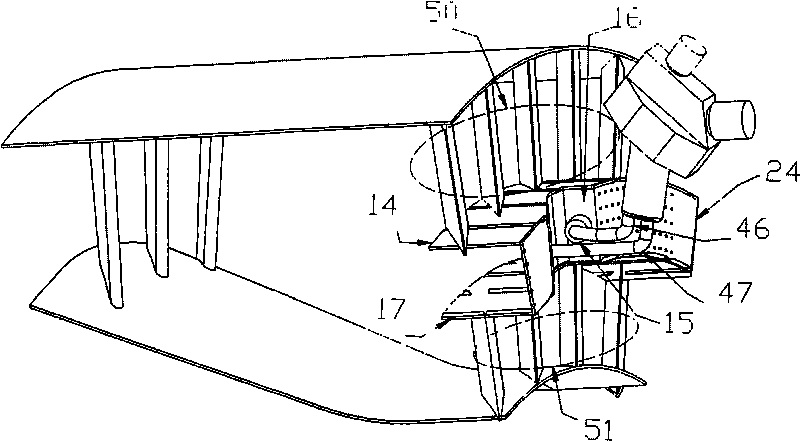

[0038] Such as figure 1 , 2 3, the combustion chamber of the present invention consists of a split diffuser 10, a combustion outdoor casing 12, a combustion chamber casing 11, a central cavity rear step pre-combustion stage 44, and an outer ring bluff body flame stabilizer main combustion stage 50. The main combustion stage 51 of the inner ring bluff body flame stabilizer, the fuel supply system 48, the inner flame tube 19, the outer flame tube 20, and the outlet support plate 21 are composed.

[0039] The combustion chamber designed by the present invention adopts the concept of staged combustion. The combustion gas is all pre-burned from the central cavity to the back step to the pre-combustion stage 44, the outer ring bluff body flame stabilizer main combustion stage 50 and the inner ring bluff body flame stabilizer main combustion stage 51 Supply, do not use traditional mixing holes. The central cavity rear step pre-combustion stage 44 adopts the central cavity rear step annu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com