Combined type biological rotating disk treatment device and method using same to treat sewage

A biological turntable and treatment device technology, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of waste, low organic load, poor sanitary conditions, etc. Processing capacity, small installation space, good sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

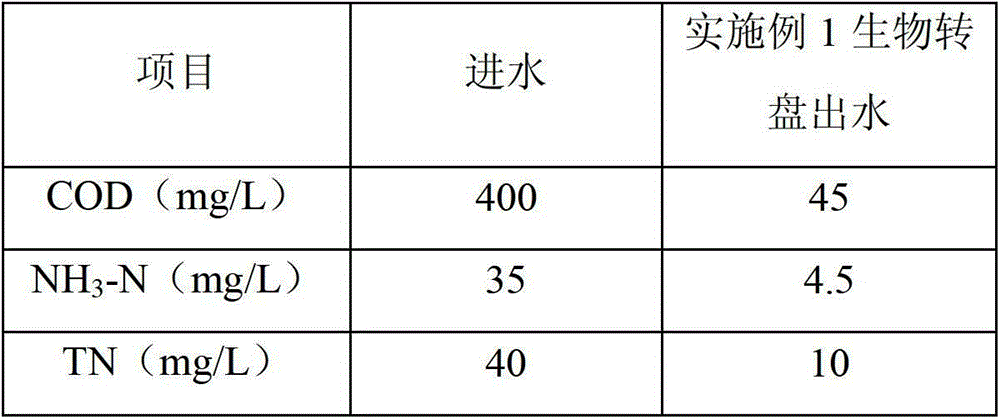

Embodiment 1

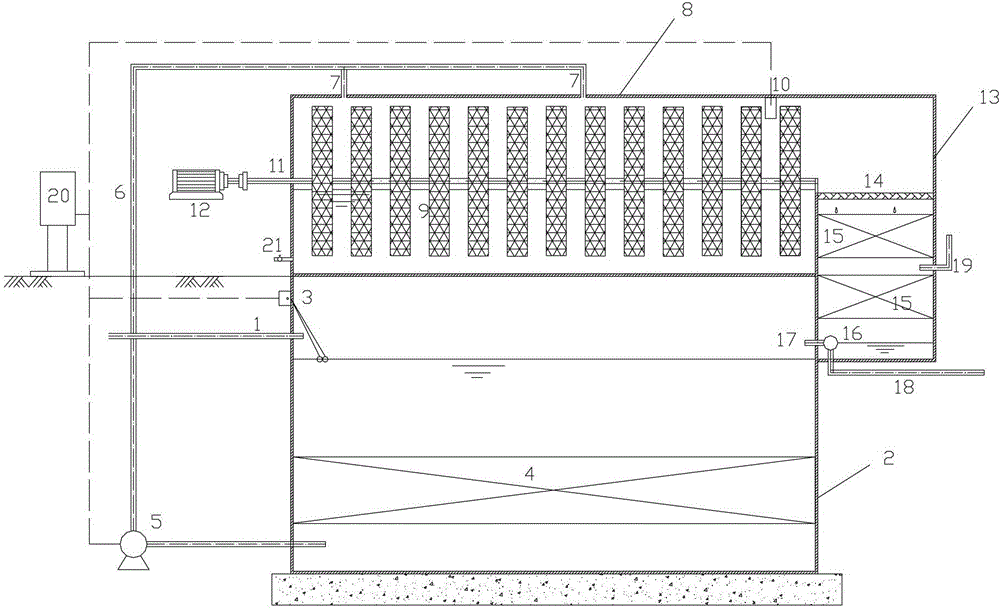

[0036] Depend on figure 1 It can be seen that the combined biological turntable treatment device of the present invention includes a water inlet pipe 1, a water inlet tank 2, a liquid level control device 3, a fixed packing 4, a jet pump 5, a pipeline 6, a shunt pipe 7, a biological turntable reactor 8, and a biological turntable reactor. Turntable disk 9, dissolved oxygen meter 10, transmission shaft 11, motor 12, biological trickling filter tank 13, water distribution plate 14, packing layer 15, outlet pipe 18, automatic control cabinet 20 and mud discharge pipe 21.

[0037] The lower part of the combined biological turntable treatment device is equipped with a water inlet tank 2; the top of the water inlet tank is equipped with a water inlet pipe 1, and the water inlet pipe 1 is connected to the external sewage source; in the water inlet tank 2, the upper layer is equipped with a liquid level control device 3, and the middle layer is equipped with a layer of fixed packing 4...

Embodiment 2

[0051] Utilize the combined type biological turntable treatment device of embodiment 1 to carry out the method for sewage treatment, sewage enters in the water inlet tank 2 from the water inlet pipe 1, and is hydrolyzed and denitrified by the microorganisms carried on the fixed filler 4 when passing through the fixed filler 4; the water inlet tank 2 The effluent is distributed to the top of the biological turntable reactor 8 through the jet pump 5 through the pipeline 6 and the shunt pipe 7; the motor 12 drives the rotation of the biological turntable disc 9 through the transmission shaft 11, and the sewage is under the action of microorganisms loaded on the biological turntable disc 9 , the organic matter is decomposed, the ammonia nitrogen is nitrified and partially denitrified simultaneously; the sludge accumulated at the bottom of the biological turntable reactor 8 is regularly discharged from the sludge discharge pipe 21; In the biological trickling filter tank 13, after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com