Method for preparing Fenton-like reaction catalyst and application thereof

A Fenton reaction and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as substandard discharge water, improve COD removal rate, reduce pollution, and meet wastewater discharge requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

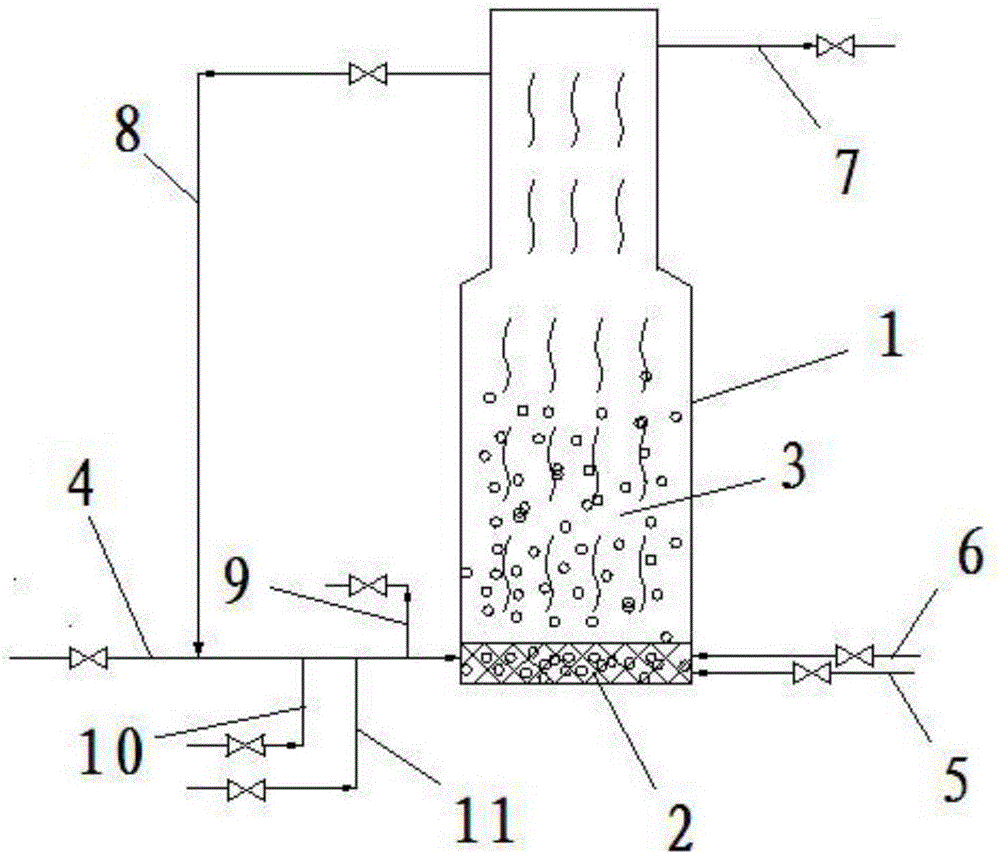

Image

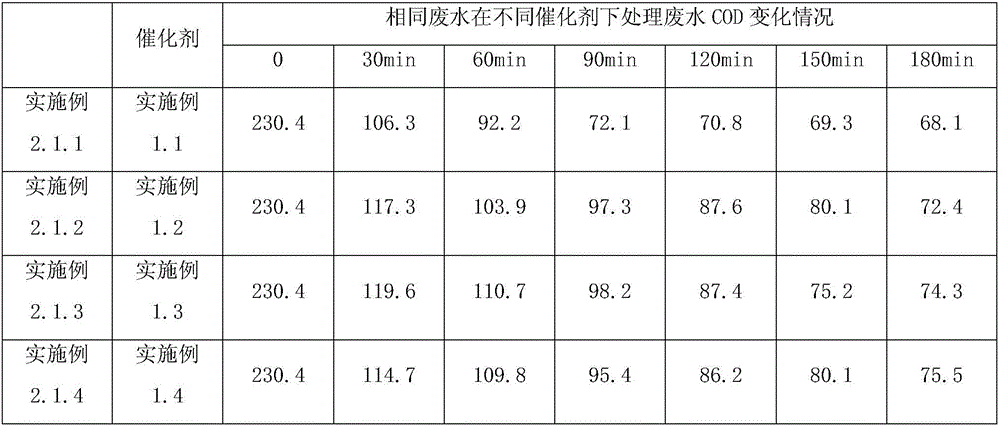

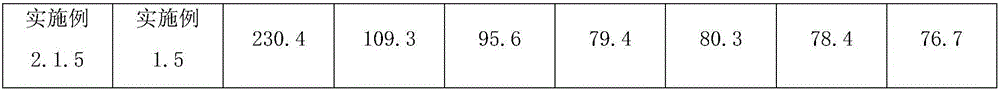

Examples

Embodiment 1

[0029] This embodiment relates to a Fenton-like reaction catalyst and a preparation method thereof.

Embodiment 11

[0031] The present embodiment adopts the following method to prepare the Fenton-like reaction catalyst:

[0032] Fe with nanoscale particle size less than 500nm 3 o 4 Powder and Pseudoboehmite powder by Fe 3 o 4 :Al 2 o 3 Mass ratio 7:3 mixed, adding about Fe 3 o 4 Powder and pseudo-boehmite powder total mass 1% surfactant ethylenediaminetetraacetic acid, stir evenly, then add about Fe 3 o 4 Powder and pseudo-boehmite powder with 3% binder sodium carboxymethyl cellulose, shaped into spherical or cylindrical or clover-shaped particles, and finally calcined at 230°C to obtain a particle size of 10 to 40 mesh Fenton reaction catalyst.

Embodiment 12

[0034] The present embodiment adopts the following method to prepare the Fenton-like reaction catalyst:

[0035] α-Fe with nanoscale particle size less than 500nm 2 o 3 Powder and γ-Al 2 o 3 Carrier powder according to α-Fe 2 o 3 :γ-Al 2 o 3 Mass ratio 2:1 mixed, adding about α-Fe 2 o 3 Powder and γ-Al 2 o 3 Surfactant polyethylene glycol (polyethylene glycol molecular weight below 1000) of powder gross mass 3%, stir evenly, then add about Fe 3 o 4 Powder and pseudo-boehmite powder with 2% binder carboxymethyl cellulose, shaped into spherical or cylindrical or clover-shaped particles, and finally calcined at 350°C to obtain phenoids with a particle size of 10-40 mesh Catalyst for the Ton reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com