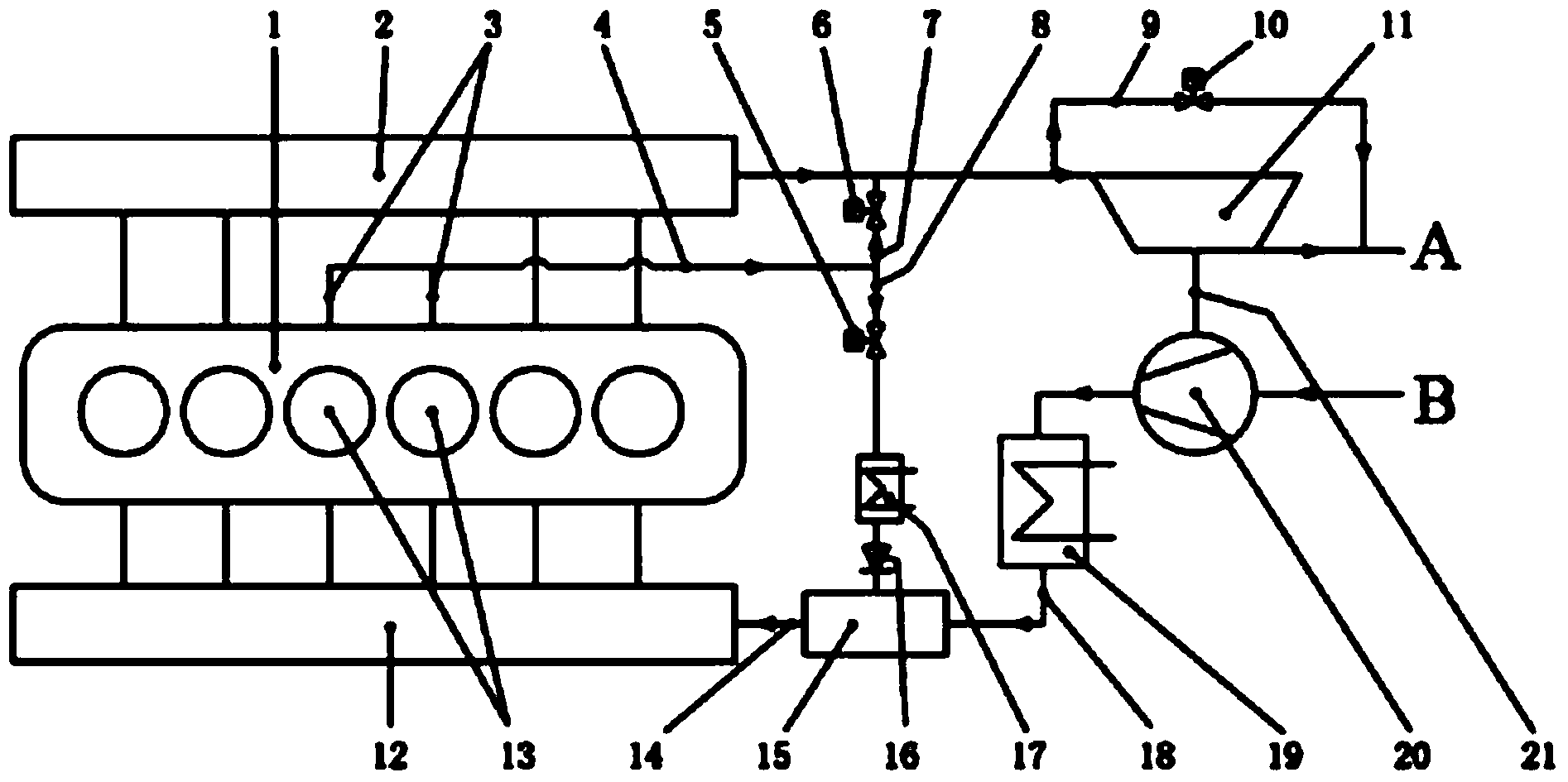

EGR (Exhaust Gas Recirculation) system used for marine medium-speed diesel engine

A diesel engine and medium-speed technology, applied in the field of EGR system, can solve the problems of high cost, complex pipeline design and control system, and no product can be found, and achieve the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment implements under the premise of the technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to the following the embodiment.

[0024] A kind of EGR system for marine medium-speed diesel engine of the present invention is specifically as follows figure 1 As shown, the individual cylinders 13 providing EGR are firstly provided in the diesel engine body 1 . The exhaust pipeline of the EGR system of the present invention is dedicated to individual cylinders 13 , and includes an exhaust branch pipe 3 and an exhaust pipe 4 . And other cylinders of diesel engine body 1 are connected with exhaust pipe 2, intake pipe 12 and turbocharger 21. Secondly the present invention also comprises EGR bypass pipeline 7 and EGR pipeline 8, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com