High-temperature stability catalyst used for three-effect catalysis

A high temperature stability, catalyst technology, applied in physical/chemical process catalysts, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that cerium zirconium solid solution cannot exist stably and the catalytic activity of catalyst decreases. , cerium zirconium solid solution phase separation and other problems, to achieve good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Ce 0.64 Zr 0.33 PD 0.03 o δ preparation

[0023] Weigh 13.90g Ce(NO 3 ) 3 ·6H 2 O, 4.40g ZrO(NO 3 ) 2 2H 2 O, 0.77ml Pd(NO 3 ) 2 The solution is mixed with 100mL deionized water, heated to make it fully dissolved to obtain solution (I); get 40ml polyoxyethylene glycol octylphenyl ether, 48ml n-hexanol and 216ml cyclohexane to prepare mixed solution (II); (I) dropwise into the solution (II), fully stirred until clear to obtain a microemulsion (III) containing metal salts; add 30% ammonia water dropwise to the microemulsion (III) until pH = 10.0, in a water bath at 30°C Stir for 4 hours and age overnight; filter, wash, and dry at 100°C to 120°C for 6 to 12 hours to obtain a precursor compound; roast at 550°C for 4 hours to obtain a fresh catalyst; roast the fresh catalyst at 1000°C for 4 hours to obtain an aged catalyst.

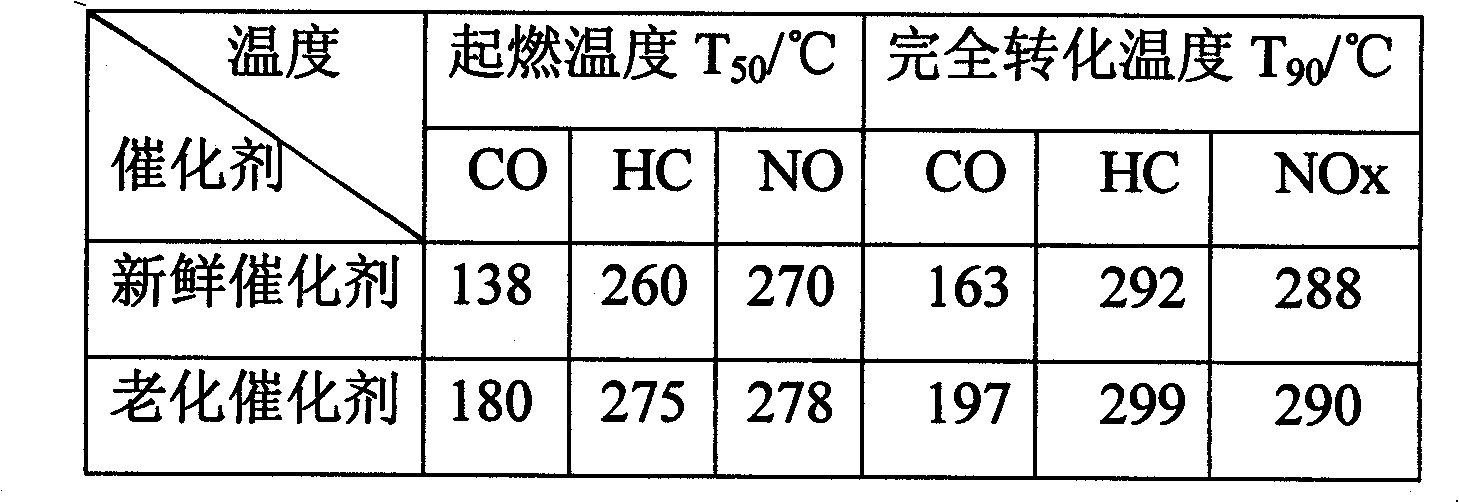

[0024] Catalyst three-way evaluation performance:

[0025]

Embodiment 2

[0026] Example 2: Ce 0.60 Zr 0.33 PD 0.03 La 0.04 o δ preparation

[0027] Weigh 13.03gCe(NO 3 ) 3 ·6H 2 O, 4.40gZrO(NO3 ) 2 2H 2 O, 1.48gLa(NO 3 ) 3 ·nH 2 O, 0.77mlPd(NO 3 ) 2 The solution was mixed with 100mL deionized water, heated to make it fully dissolved, and the following steps were the same as in Example 1.

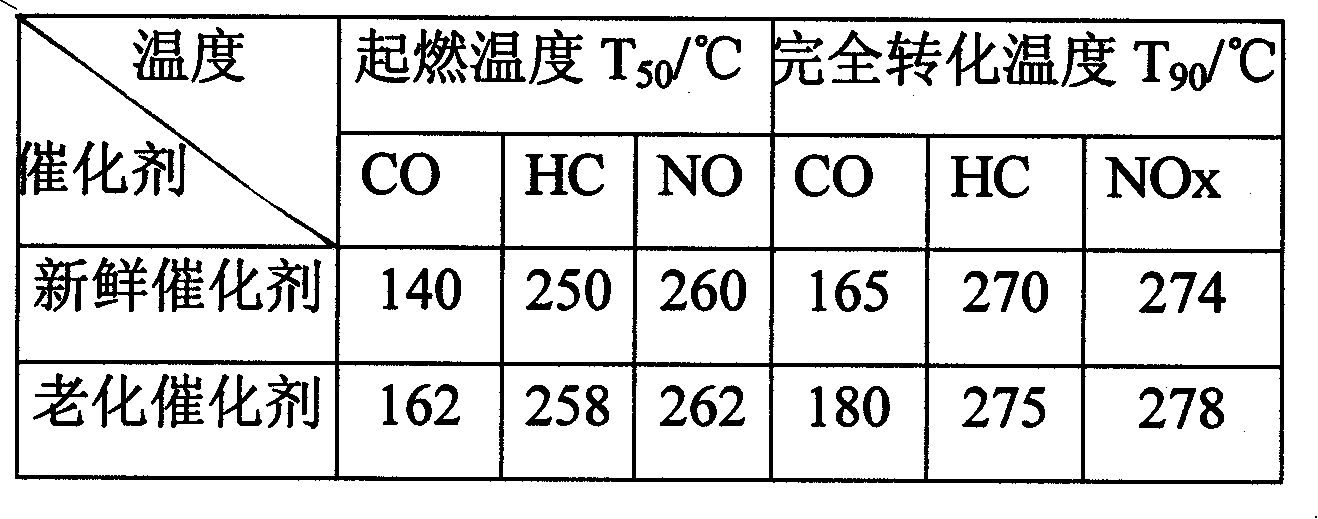

[0028] Catalyst three-way evaluation performance:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com