Method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water

A catalytic iron, refractory technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. and the effect of the impact of the water load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

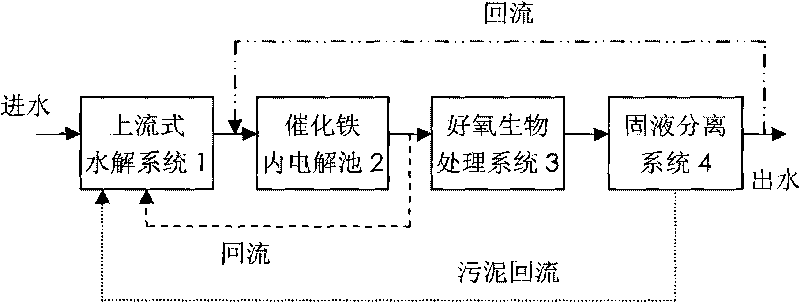

Image

Examples

Embodiment 1

[0023] 1. The chemical industrial park wastewater that has been preliminarily treated by grille and sand settling enters the upstream hydrolysis system 1 directly, and the residence time in this system is 5.5h. The hydrolysis system adopts the biofilm type. The hydrolysis tank requires a good water distribution system and Mud discharge system.

[0024] 2. Catalytic iron inner electrolytic cell 2 The catalytic iron filler is composed of iron shavings and copper shavings, the mass ratio of the two is 20:1, and the bulk specific gravity is 0.2. The contact time of the filling area is 1.5h, and it is required to be completely submerged in water. The catalytic iron is required to be upflow type, and a good water distribution system and slag discharge system are required. The reflux ratio of the effluent of the catalytic iron inner electrolytic cell 2 to the upflow hydrolysis system 1 is 100%.

[0025] 3. The aerobic biological treatment system 3 uses suspended biological carriers...

Embodiment 2

[0029] 1. The printing and dyeing wastewater treated by the grid directly enters the upstream hydrolysis system 1, and the residence time in this system is 9.0h. The hydrolysis system adopts the suspended sludge type, and a good water distribution system and sludge discharge system are required in the hydrolysis tank.

[0030] 2. Catalytic iron inner electrolytic cell 2 The catalytic iron filler is composed of iron shavings and copper shavings, the mass ratio of the two is 10:1, and the bulk specific gravity is 0.3. The contact time of the filling area is 0.5h, and it is required to be completely submerged in water. The catalytic iron is required to be upflow type, and a good water distribution system and slag discharge system are required. The reflux ratio of the effluent from the catalytic iron inner electrolytic cell 2 to the upflow hydrolysis system 1 is 40%.

[0031] 3. Aerobic biological treatment system 3 adopts elastic packing carrier. For the fluid state, the plug-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com