Hydrophobic white carbon production fluidized bed reactor capable of recycling materials

A fluidized bed reactor, hydrophobic technology, applied in the field of fluidized bed, can solve the problems of limited heat removal, inconvenient installation and maintenance, and unstable reaction, so as to improve the effect and stability, facilitate installation and maintenance, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

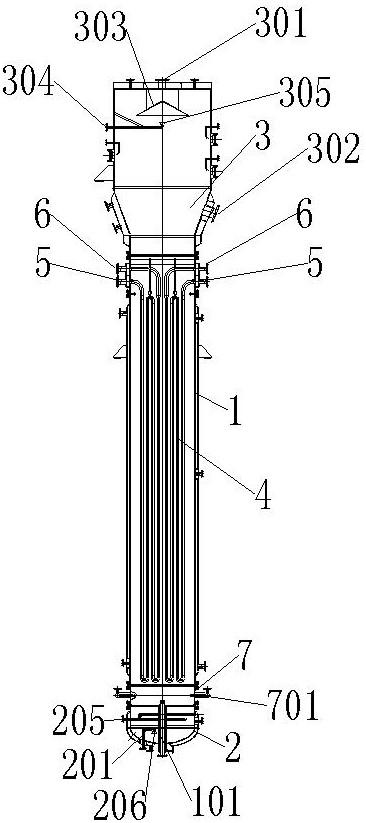

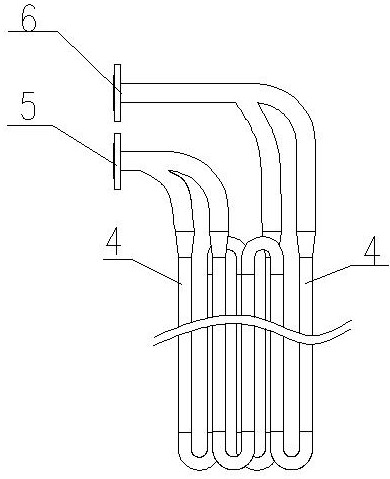

[0030] This embodiment provides a fluidized bed reactor for the production of hydrophobic silica with recyclable materials, such as Figures 1 to 3As shown, it mainly includes a bed body 1, a gas distribution chamber 2 is installed at the bottom of the bed body 1, an upper head 3 is installed at the top, and six sets of heat exchange tube assemblies are installed inside the bed body 1, and each set of heat exchange tube assemblies has at least It includes two U-shaped heat exchange tube groups 4, and each U-shaped heat exchange tube group 4 is composed of at least three U-shaped heat exchange tubes connected in series. The two U-shaped heat exchange tube groups 4 share the same heat transfer oil inlet 5 and the same heat transfer oil outlet 6 . A feed pipe 101, a distribution plate 202, and several gas distribution heads 203 are installed in the gas distribution chamber 2, the feed pipe 101 is arranged concentrically with the gas distribution chamber 2, and is fixedly installe...

Embodiment approach 2

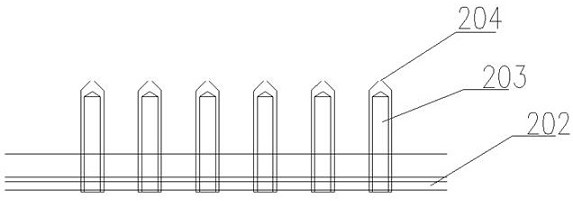

[0039] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, the gas outlet 204 of the gas distribution head 203 is set on the top of the gas distribution head 203. It is more preferred for large solid materials, but when it is necessary to pass into the bed body 1 with solid materials such as white carbon black, since the gas outlet 204 is blowing upward, it will result in smaller quality solid materials. Blown to the upper part of the bed body 1 quickly with the airflow, it is easy to cause uneven dispersion of solid materials and uneven contact with the gas in the lower part, which affects the uniformity and stability of the reaction and the content of active ingredients in the reaction product.

[0040] In this embodiment, the gas outlet 204 of the gas distribution head 203 is set on the side wall of the gas distribution head 203, and the gas outlet 204 is an inclined outlet with an angle α1 of 45° to the central axis of the...

Embodiment approach 3

[0044] This embodiment is a further improvement of Embodiment 2, the main improvement is that in this embodiment, as Image 6 , the distribution plate 202 in the gas distribution chamber 2 is a V-shaped structure with an included angle α2 of 140°. Compared with the distribution plate with a planar structure, the design of the distribution plate 202 with a V-shaped structure can increase the number of gas distribution heads 203 installed on it, so that the gas is distributed more densely, and the dispersed materials are also dispersed more uniformly.

[0045] Apart from this, this embodiment is completely the same as Embodiment 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com