Method of preparing anatase structured highlight catalytic active nano-TiO2

A catalytic activity, anatase technology, applied in the field of photocatalysts and solar cells, can solve the problems of small specific surface area and achieve the effect of high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 7ml of tetrabutyl titanate (TEOT) and 4.6ml of glacial acetic acid into a four-necked flask, and at the same time add 10ml of absolute ethanol as a solvent, and stir to obtain a clear light yellow solution 1;

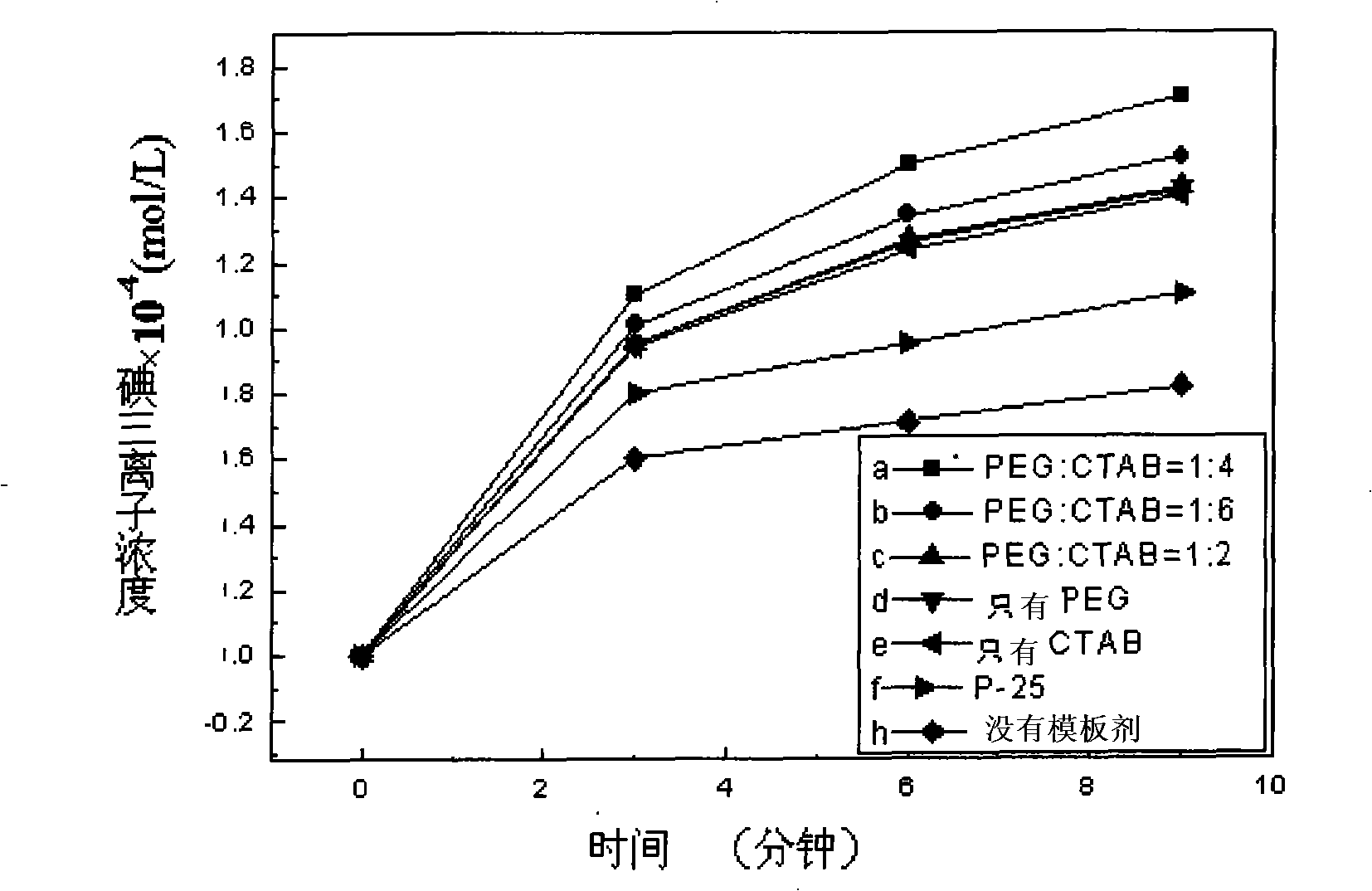

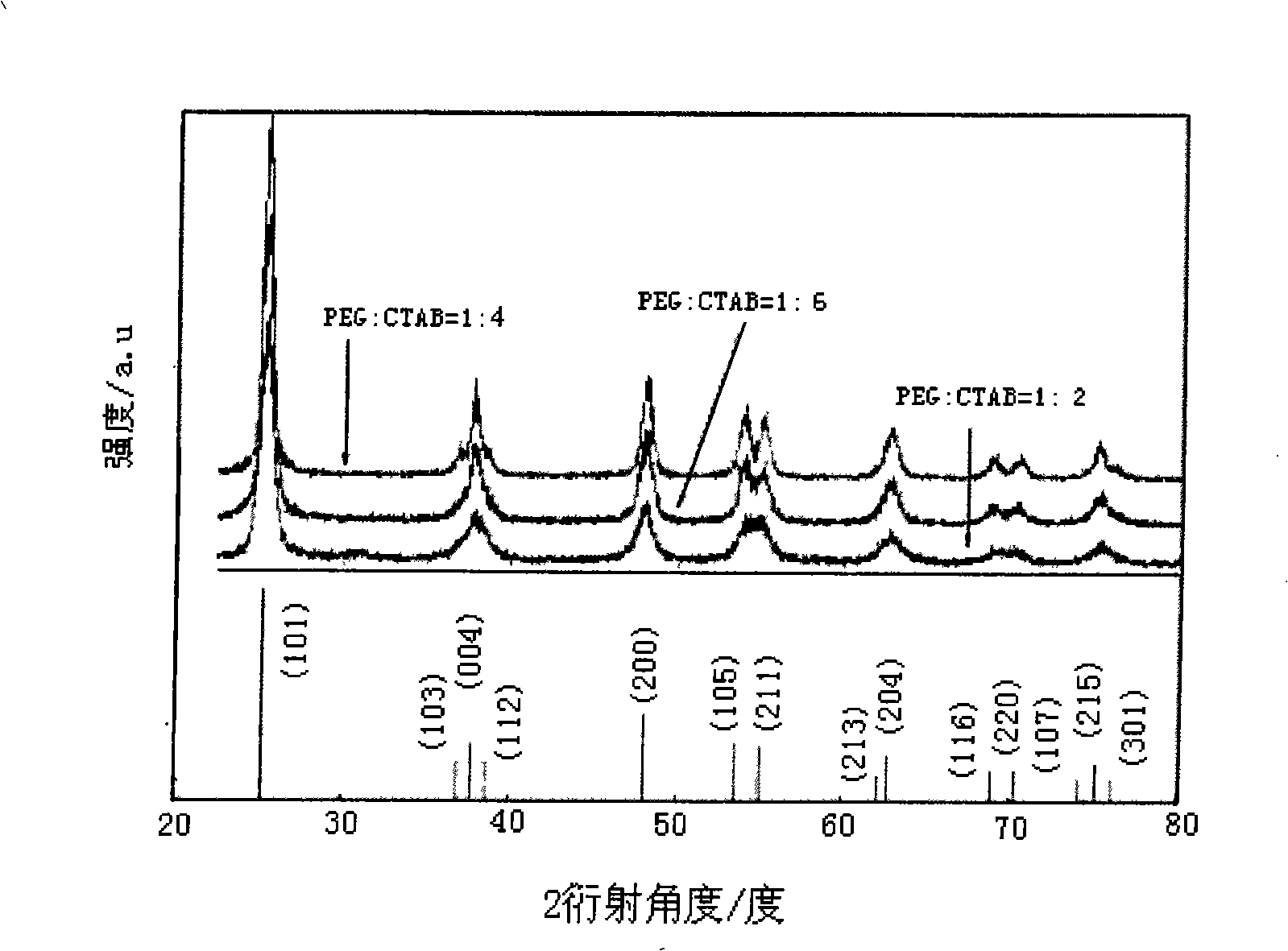

[0025] (2) Weigh polyethylene glycol (PEG4000) and cetyltrimethylammonium bromide (CTAB) as a double-template agent so that the molar ratio is 1:4 respectively; add 15ml of absolute ethanol solvent (template agent The mass ratio with absolute ethanol is 1:10), stirring to dissolve the template agent to obtain solution 2;

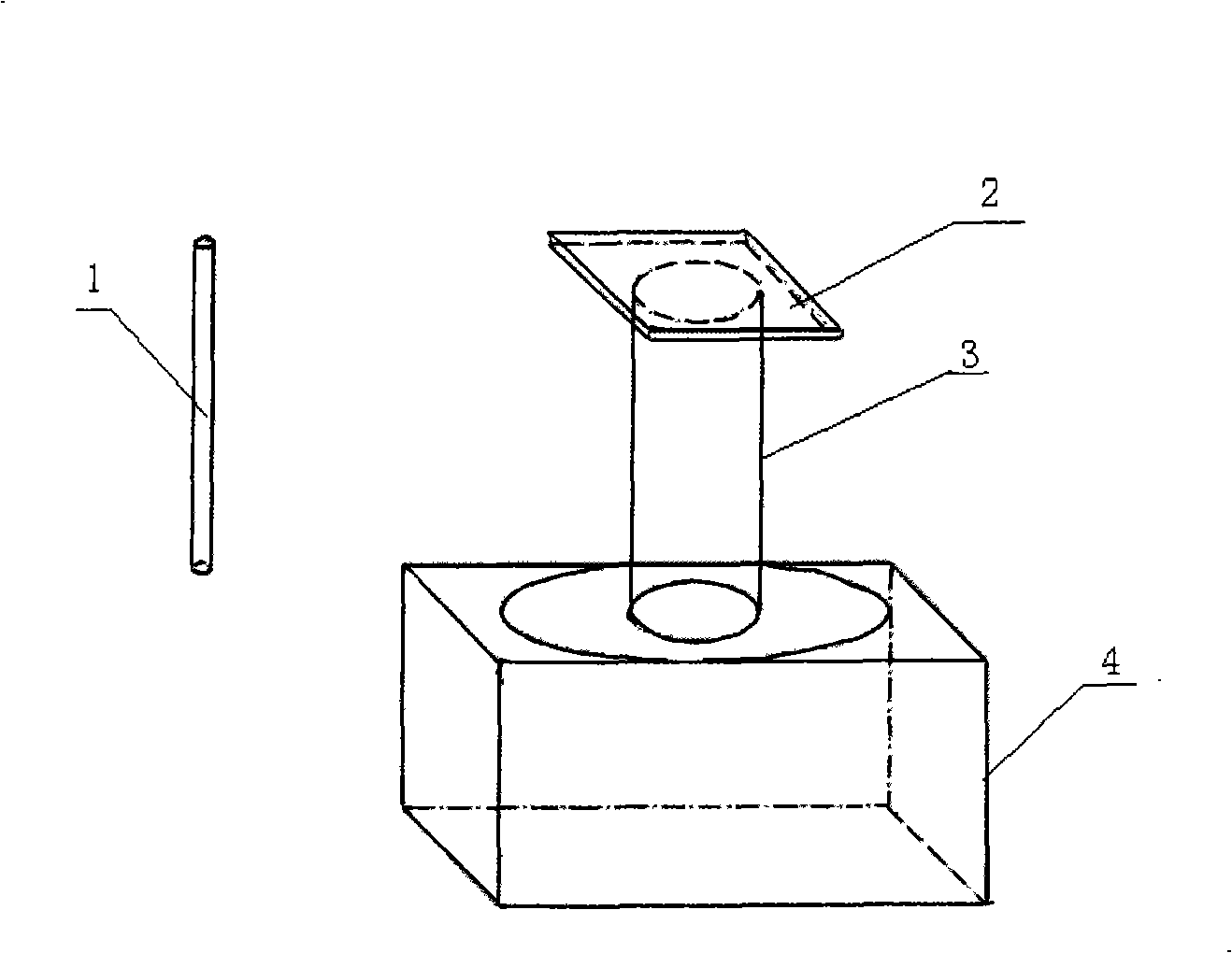

[0026] (3) Mix solution 2 with solution 1 in the four-necked flask, add 1.44ml of water, and carry out the whole reaction at room temperature. After stirring for 10 hours to clarify, transfer the solution to a crystallization tank and place it in a constant temperature box at 60°C. Let stand for 3 days to form a gel, and dry at 80°C for 24 hours;

[0027] (4) The dry powder was roasted in a muffle furnace at 450° C. for 3 hours, and fi...

Embodiment 2

[0030] Titanium dioxide powder was obtained in the same manner as described in Example 1, except that the molar ratio of template agent polyethylene glycol (PEG4000) to cetyltrimethylammonium bromide (CTAB) was changed to 1:6.

[0031] The properties of this powder were measured and shown in Table 1.

Embodiment 3

[0033] Titanium dioxide particles were obtained in the same manner as described in Example 1, except that the molar ratio of template agent polyethylene glycol (PEG4000) to cetyltrimethylammonium bromide (CTAB) was changed to 1:2.

[0034] The properties of this powder were measured and shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com