Formula of special completely mixed pellet feed for fattening sheep and preparation method

A technology for pellet feed and fattening sheep, which is applied in animal feed, animal feed, application and other directions, can solve the problems of unbalanced ratio of nutrients and fine to coarse, unable to meet the nutritional needs of sheep, low feed conversion rate, etc., so as to improve reproductive performance. , good development prospects, the effect of excellent semen quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

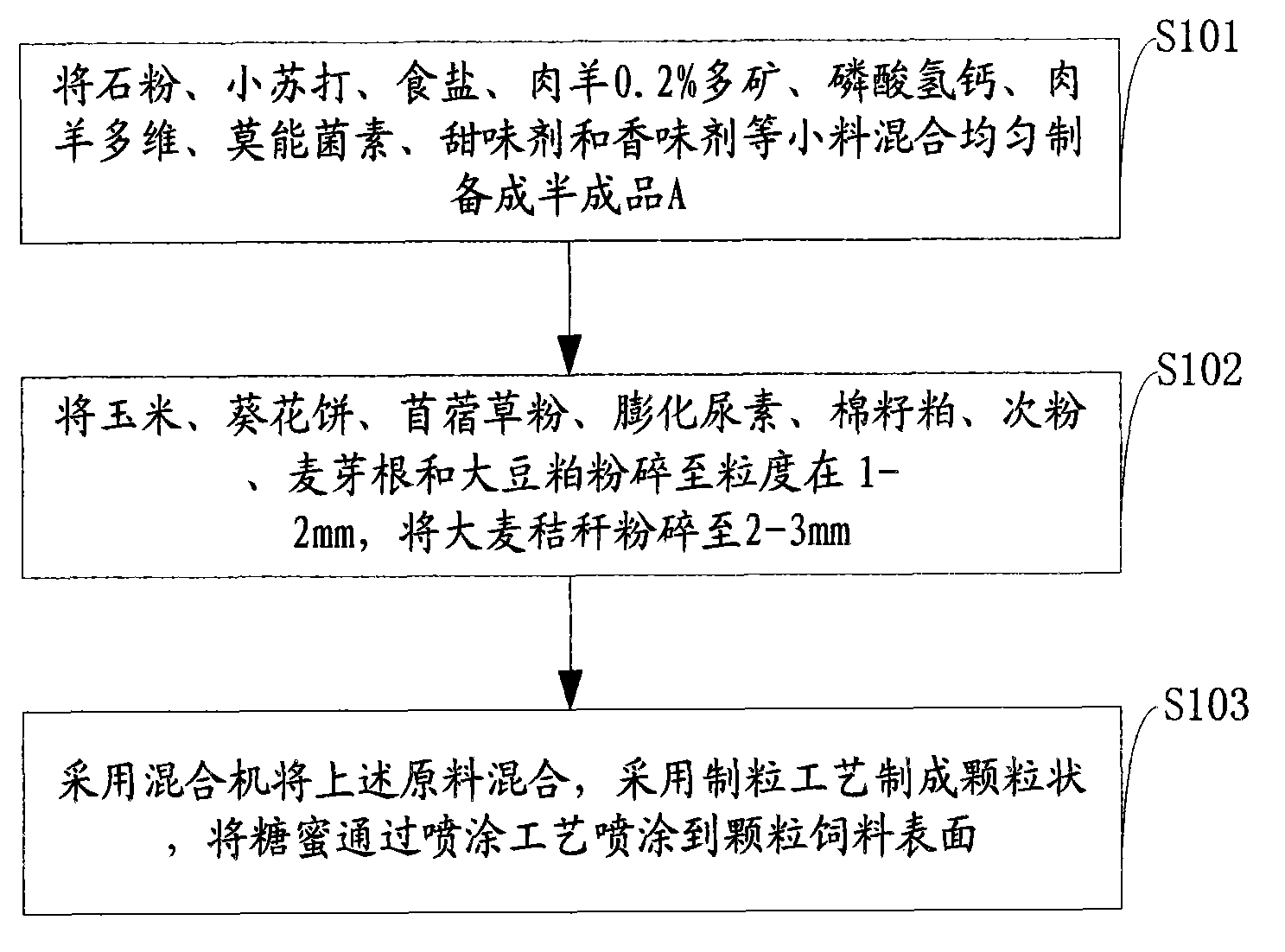

[0033] Such as figure 1 As shown, another object of the embodiments of the present invention is to provide a preparation method of the full mixed pellet feed for fattening sheep, the preparation method comprising the following steps:

[0034] Step 1. Mix small ingredients such as stone powder, baking soda, salt, mutton sheep 0.2% polymineral, calcium hydrogen phosphate, mutton multidimensional, monensin, sweetener and flavoring agent to prepare a semi-finished product A;

[0035] Step 2, crushing corn, sunflower cake, alfalfa powder, expanded urea, cottonseed meal, secondary meal, malt root and soybean meal to a particle size of 1-2 mm, and crushing barley straw to 2-3 mm;

[0036] Step 3, using a mixer to mix the above-mentioned raw materials, making them into granules through a granulation process, and spraying molasses onto the surface of the pellet feed through a spraying process.

[0037] As an optimization scheme of the embodiment of the present invention, the weight fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com