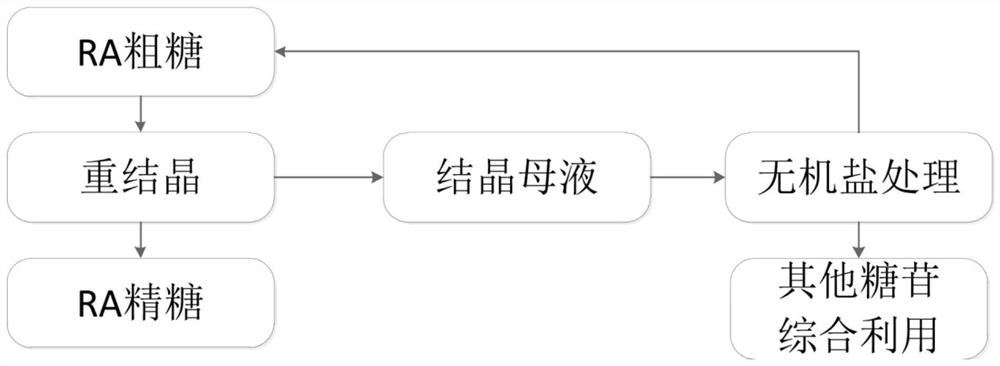

Method for recovering rebaudioside A from primary crystallization mother liquor of steviol glycosides (SGs)

A technology of crystalline mother liquor and stevioside, which is applied in the field of separation of natural high-intensity sweeteners, can solve the problems of difficult recovery of rebaudioside A, and achieve the effect of simple and efficient recovery process, low energy consumption and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

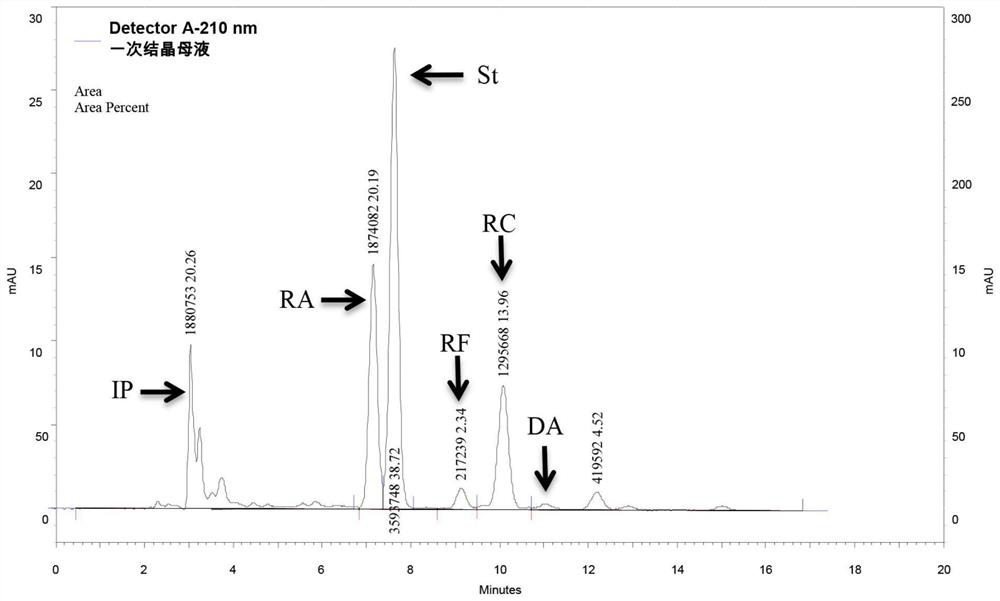

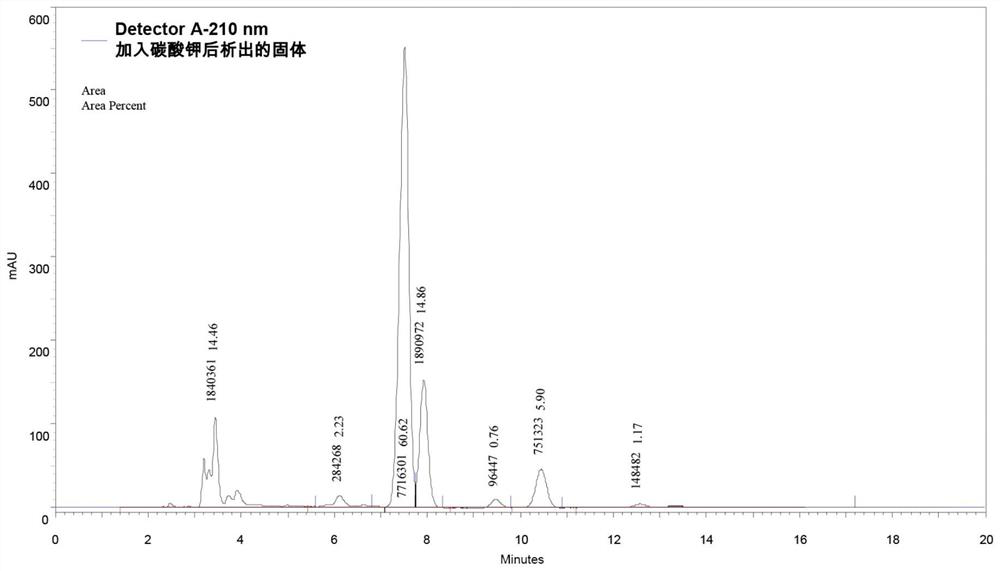

[0033] Use a pipette to accurately measure 50ml of the mother liquor for primary crystallization and dry at 105°C to a constant weight to obtain a solid 6.168g, of which m RA =1874.5mg, m St =2982.7mg, RA / St=0.6284, and the ratio of RA peak area is 20.19%. Take another 50ml of the mother liquor of stevia crystallization, add dropwise 0.2g / ml potassium carbonate aqueous solution 2.0ml under stirring conditions at 25°C, continue stirring (n=100rpm) for 30min, centrifuge and filter and dry at 60°C for 24h to obtain a solid 1.809 g, where m RA =1322.0mg, m St =291.2mg, RA / St=4.54, the ratio of RA peak area is 60.62%, the recovery rate of RA is 70.5%, and the impurity content drops from 20.3% in the mother liquor to 14.4% (see attached Figure 2~4 )

Embodiment 2

[0035] Take 50ml primary crystallization mother liquor, add dropwise an appropriate concentration of potassium carbonate aqueous solution at different temperatures, stir for 30 minutes, and measure the content of each substance in the remaining mother liquor as shown in the table below.

[0036]

[0037]

Embodiment 3

[0039] Take 50ml primary crystallization mother liquor, add dropwise an appropriate concentration of potassium carbonate aqueous solution at 25°C, stir for 60min, and measure the content of each substance in the remaining mother liquor as shown in the table below.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com