Method for preparing rebaudioside C

A technology of recrystallization and ethanol, which is applied in the field of medicine, can solve problems such as low sweetness, heavy bitterness and astringent taste, and great influence on product quality, and achieve the effect of simple and easy method and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 3Kg of stevioside (RC content is 3.5%, RA content is 38%, ST content is 33.58%), add 30L methanol to dissolve, heat and dissolve at 40°C, after cooling down to room temperature, put it in a water bath at 4°C and stir for crystallization for 24 hours , filtered, the crystallization mother liquor was decompressed and the solvent was recovered to obtain 1.52Kg of concentrate, which was set aside;

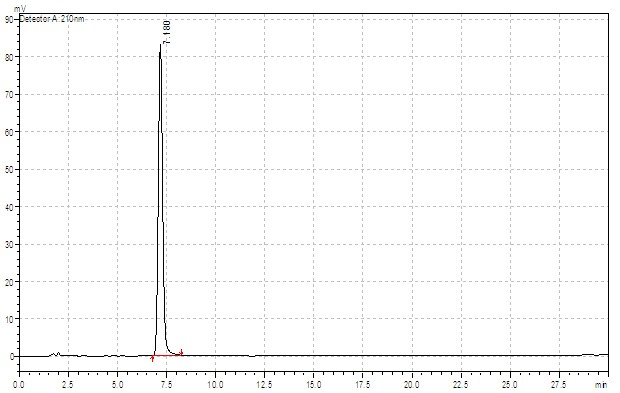

[0026] Take 20Kg of silica gel (200-300 mesh), add chloroform-92% ethanol (4:1) mixed solvent, fully remove air bubbles, put it into a chromatography column with a diameter of 273mm and a height of 1.5m; take another 1.0Kg of concentrate , add an appropriate amount of ethanol to dissolve, mix in 2.5Kg 200-300 mesh silica gel, and dry in an oven at 45°C for 24 hours; put the mixed silica gel into the chromatography column, and mix it with chloroform-92% ethanol (4:1) Solvent for elution, 10L / part of eluent collected, using TLC monitoring, TLC conditions: developer is n-butan...

Embodiment 2

[0028] Take 3Kg of stevioside ((RC content is 3.5%, RA content is 38%, ST content is 33.58%), add 24L methanol to dissolve, heat and dissolve at 40°C, after cooling down to room temperature, place it in a water bath at 4°C and stir to crystallize for 36 hour, filtered, and the crystallization mother liquor was decompressed and recovered solvent to obtain concentrate 1.56Kg, for subsequent use;

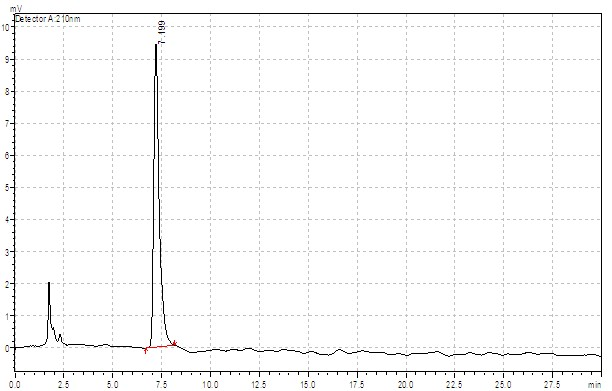

[0029] Take 25Kg of silica gel (200-300 mesh), add chloroform-92% ethanol (4:1) mixed solvent, fully remove the air bubbles, put it into a chromatography column with a diameter of 273mm and a height of 1.5m; take another 1.0Kg of concentrate , add an appropriate amount of ethanol to dissolve, mix in 2.5Kg 200-300 mesh silica gel, and dry in an oven at 45°C for 24 hours; put the mixed silica gel into the chromatography column, and mix it with chloroform-92% ethanol (4:1) Solvent for elution, 10L / part of eluent collected, using TLC monitoring, TLC conditions: developer is n-butanol-glaci...

Embodiment 3

[0031] Take 3Kg of stevioside (RC content is 10.80%, RA content is 37.14%, ST content is 35.53%), add 36L methanol to dissolve, heat and dissolve at 40°C, after cooling down to room temperature, put it in a water bath at 4°C and stir for crystallization for 48 hours , filtered, the crystallization mother liquor was decompressed and the solvent was recovered to obtain 1.54Kg of concentrate, which was set aside;

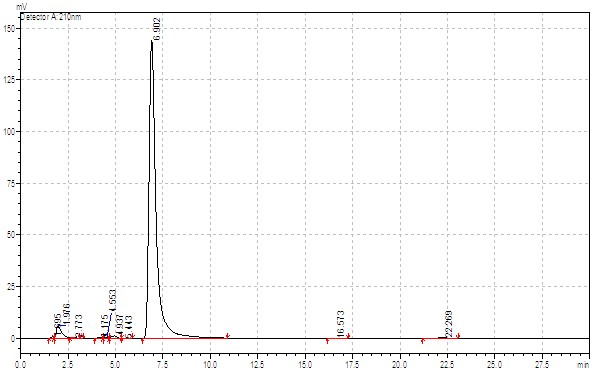

[0032] Take 30Kg of silica gel (200-300 mesh), add chloroform-95% ethanol (3:1) mixed solvent, fully remove air bubbles, put it into a chromatography column with a diameter of 273mm and a height of 1.5m; take another 1.0Kg of concentrate , add an appropriate amount of ethanol to dissolve, mix in 2.5Kg 200-300 mesh silica gel, and dry in an oven at 45°C for 24 hours; put the mixed silica gel into the chromatography column, and mix it with chloroform-95% ethanol (3:1) Solvent for elution, 10L / part of eluent collected, using TLC monitoring, TLC conditions: developer is n-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com