Technology for purifying rebaudioside C

A rebaudioside and process technology, applied in the field of extraction and purification of active ingredients in plants, can solve the problem of low RC content of products, and achieve the effects of increasing RC content and yield, increasing yield, increasing content and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

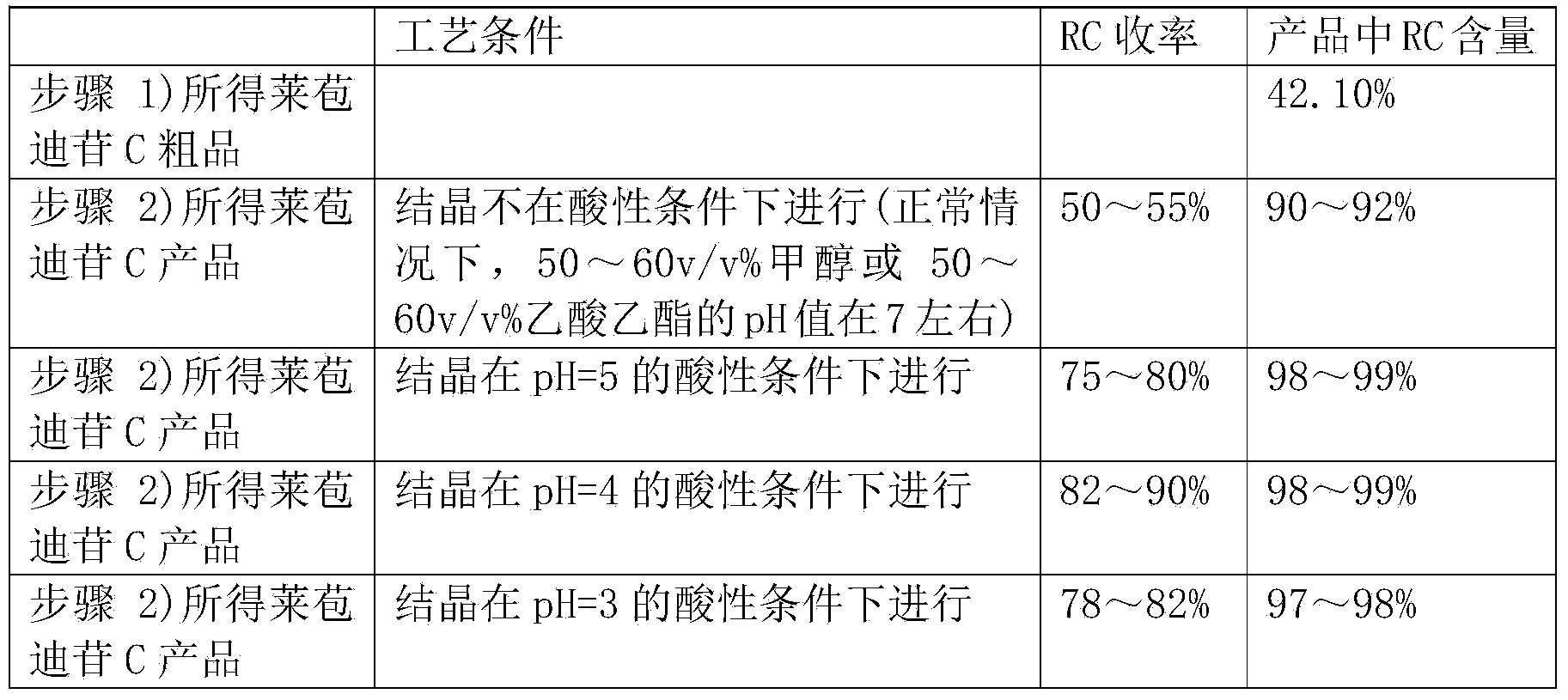

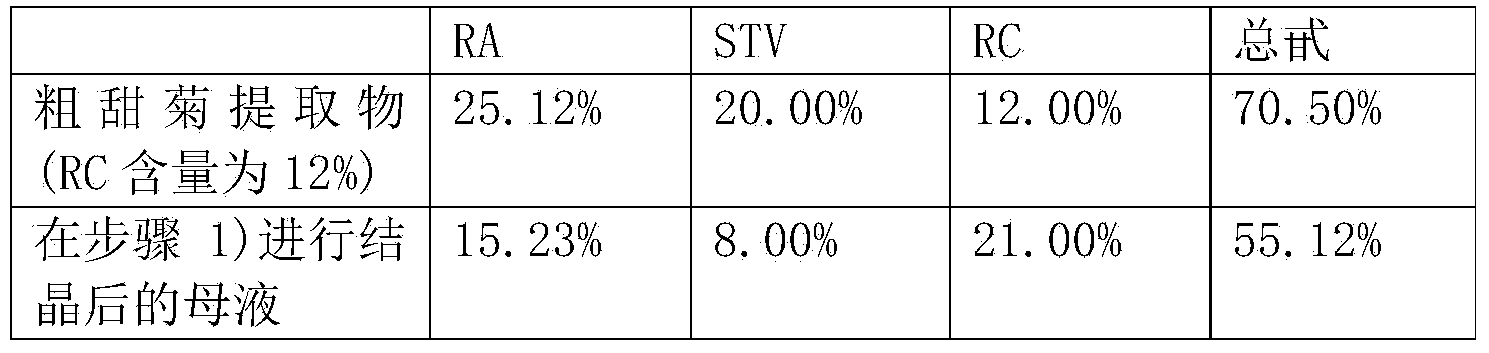

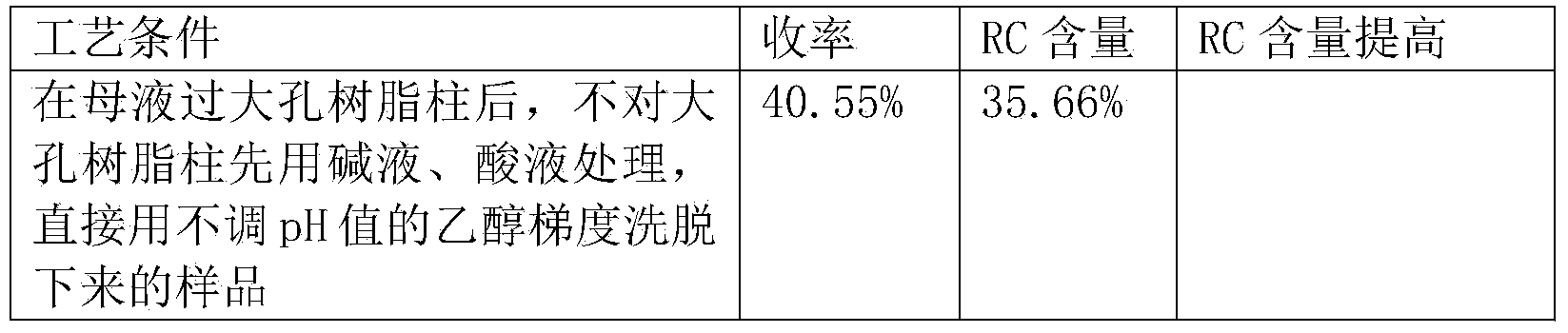

[0035] 1) Take 300g of crude stevia extract dry powder with RC content of 10%, crystallize with 60v / v% methanol of 4 times the amount of the raw material, and then put the mother liquor into the D101 macroporous resin column, first use 1w / w of 2 times the volume of the column bed % sodium hydroxide aqueous solution to wash the column, then wash the column with 2 times the column bed volume of 1w / w% hydrochloric acid aqueous solution, then wash the resin column with water until the effluent is neutral, and then use 2.5 times the column bed volume to pH 3 20v / v% ethanol (adjust the pH value with formic acid) for elution, and finally elute with 60v / v% ethanol (adjust the pH value with formic acid) at pH 7.5, track and detect with thin layer chromatography, and collect 60v / v% ethanol The eluate was concentrated and dried to obtain 70 g of the crude product of rebaudioside C; the total stevioside content in the obtained crude product was 91%, wherein the RC content was 40.5%, and th...

Embodiment 2

[0041] 1) Take 400g of thick stevia extract dry powder with RC content of 11%, crystallize with 70v / v% ethanol of 4 times the amount of the raw material, and then enter the mother liquor into the LX-8 macroporous resin column, first use 0.5 Wash the column with w / w% sodium hydroxide aqueous solution, then wash the column with 1w / w% sulfuric acid aqueous solution of 2 times the column bed volume, then wash the resin column with water until the effluent is neutral, and then use 2.9 times the column bed volume Elute with 25v / v% ethanol at pH 3.5 (adjust the pH value with glacial acetic acid), and finally elute with 70v / v% ethanol at pH 8.0 (adjust the pH value with glacial acetic acid), track and detect with thin layer chromatography, and collect The 70v / v% ethanol eluate was concentrated and dried to obtain 90g of a crude product of rebaudioside C; the content of total steviosides in the obtained crude product was 93%, wherein the content of RC was 41.5%, and the content of RA wa...

Embodiment 3

[0044] 1) Take 350g of thick stevia extract dry powder with RC content of 13%, crystallize with 75v / v% acetone of 4 times the amount of the raw material, and then enter the mother liquor into the HP-20 macroporous resin column, first use 1.5 Wash the column with w / w% potassium hydroxide aqueous solution, then wash the column with 3 times the column bed volume of 1w / w% hydrochloric acid aqueous solution, then wash the resin column with water until the effluent is neutral, and then use 3 times the column bed volume Elute with 28v / v% ethanol at pH 4 (adjust the pH with glacial acetic acid), and finally elute with 65v / v% ethanol at pH 7.5 (adjust the pH with glacial acetic acid). The 65v / v% ethanol eluate was concentrated and dried to obtain 103g of a crude product of rebaudioside C; the content of total steviol glycosides in the crude product was 94%, of which RC content was 43% and RA content was 33%;

[0045] 2) Add the rebaudioside C crude product obtained above into a crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com