Method for purifying rebaudioside c

一种乙酸乙酯、丁醇的技术,应用在化学仪器和方法、有机化学、糖衍生物等方向,能够解决产率物质纯度未公开等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1; Initial Purification of Rebaudioside C from Crude Extract

[0035] Using a number of different solvent systems, a mixture of acetone and water was observed to be a suitable solvent for the recrystallization of rebaudioside C from the crude starting material (i.e., the "waste" produced in the rebaudioside A production process) . Therefore, the yield of recrystallized rebaudioside C from the starting material was determined. For these experiments, the crude starting material was mixed with acetone / water (85 / 15, w / w). Typically, for 1 g of solid, 4-6 g of solvent is used. The mixture was heated to 48°C and all solids were allowed to dissolve. The mixture was cooled to room temperature and stirred for 3-4 days. The solution was filtered to collect a white precipitate, which was then washed with acetone and dried under vacuum at 50°C for 8 hours.

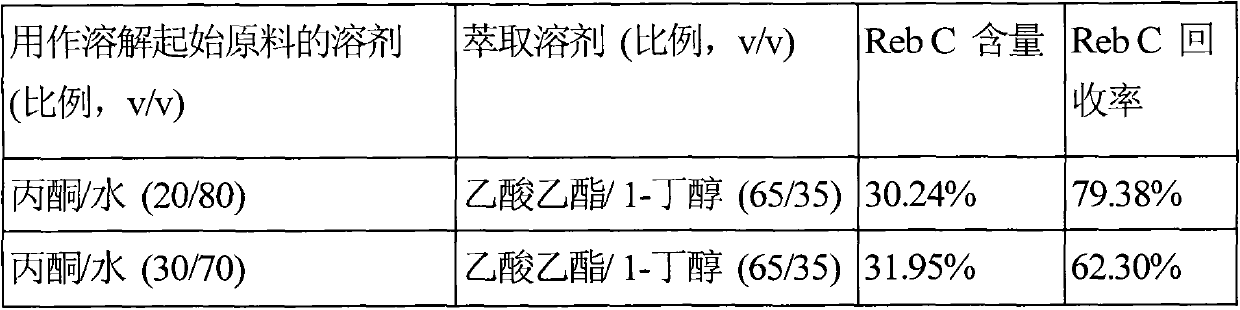

[0036] Table 2

[0037] Amount of crude starting material

RebC content in crude product

The am...

Embodiment 2

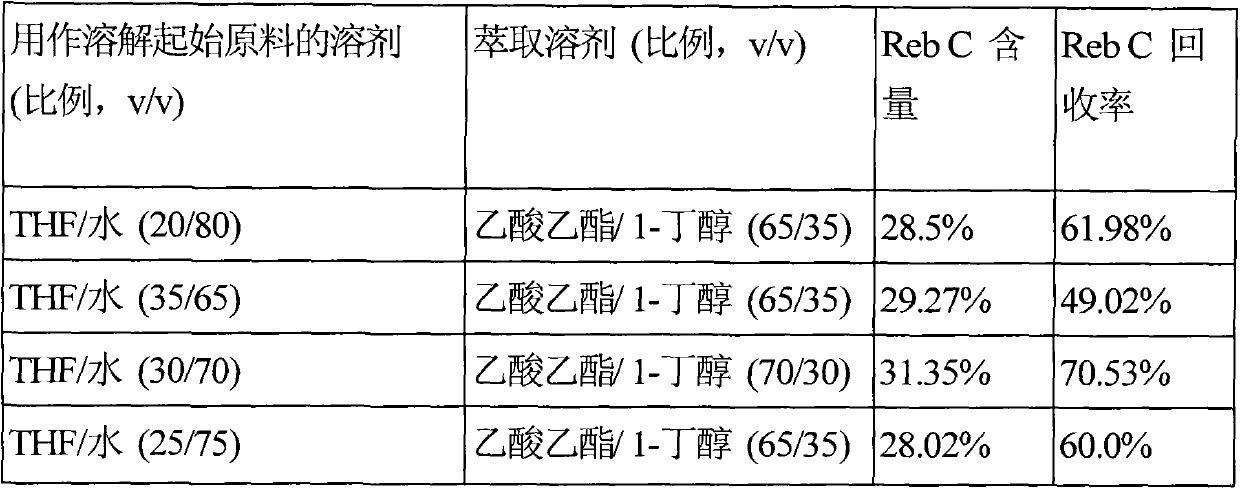

[0047] Example 2: Purification of Rebaudioside C

[0048] 20 g of starting material are dissolved in 500 ml of a THF / water mixture containing 70-80% (preferably 75% (v / v)) water. The resulting solution was extracted twice with 500 ml of ethyl acetate / 1-butanol mixture (85 / 15, v / v). The 1-butanol / ethyl acetate layer was removed.

[0049] The THF-water phase is then further extracted twice with 500 ml of an ethyl acetate / butanol mixture containing 30-40% 1-butanol, preferably 35% (v / v). The ethyl acetate / butanol layers from the two extractions were combined and concentrated under vacuum to give 8.70 g of material. It was determined by HPLC analysis that the content of rebaudioside C in this substance reached 24.5% (Table 5).

[0050] table 5

[0051] Retention time (minutes)

components

total percentage

12.702

unknown

1.10

15.722

unknown

4.62

18.547

unknown

4.20

22.811

unknown

1.06

24.473

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com