Novel polymorphs of rebaudioside C and methods for making and using the same

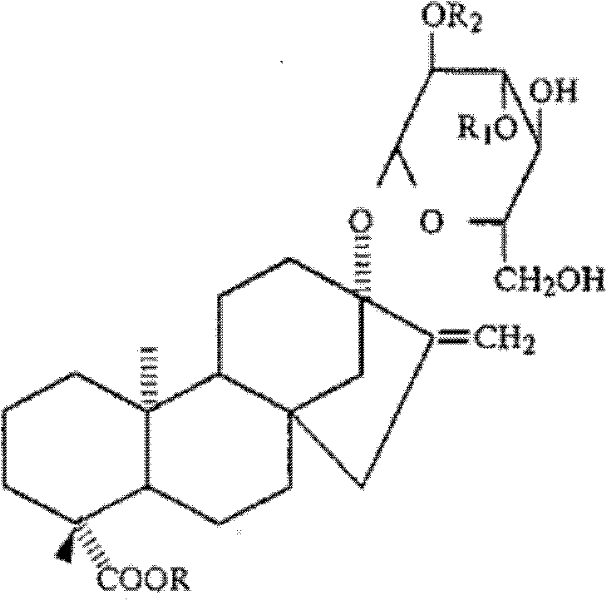

A technology of rebaudioside and baudioside, which is applied in the field of new polymorphs of rebaudioside C and its preparation and use, and can solve the problems of a large number of reaction steps, purification steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

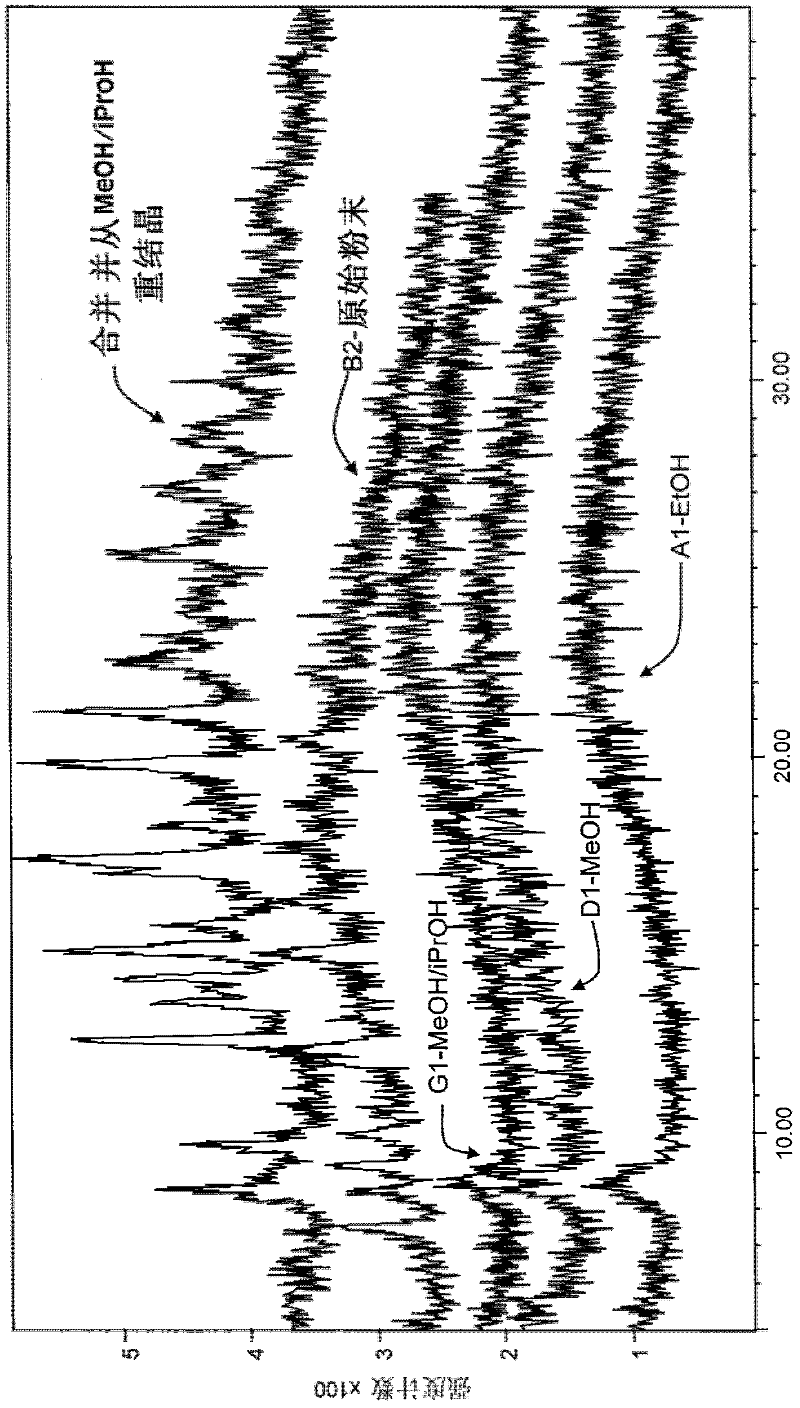

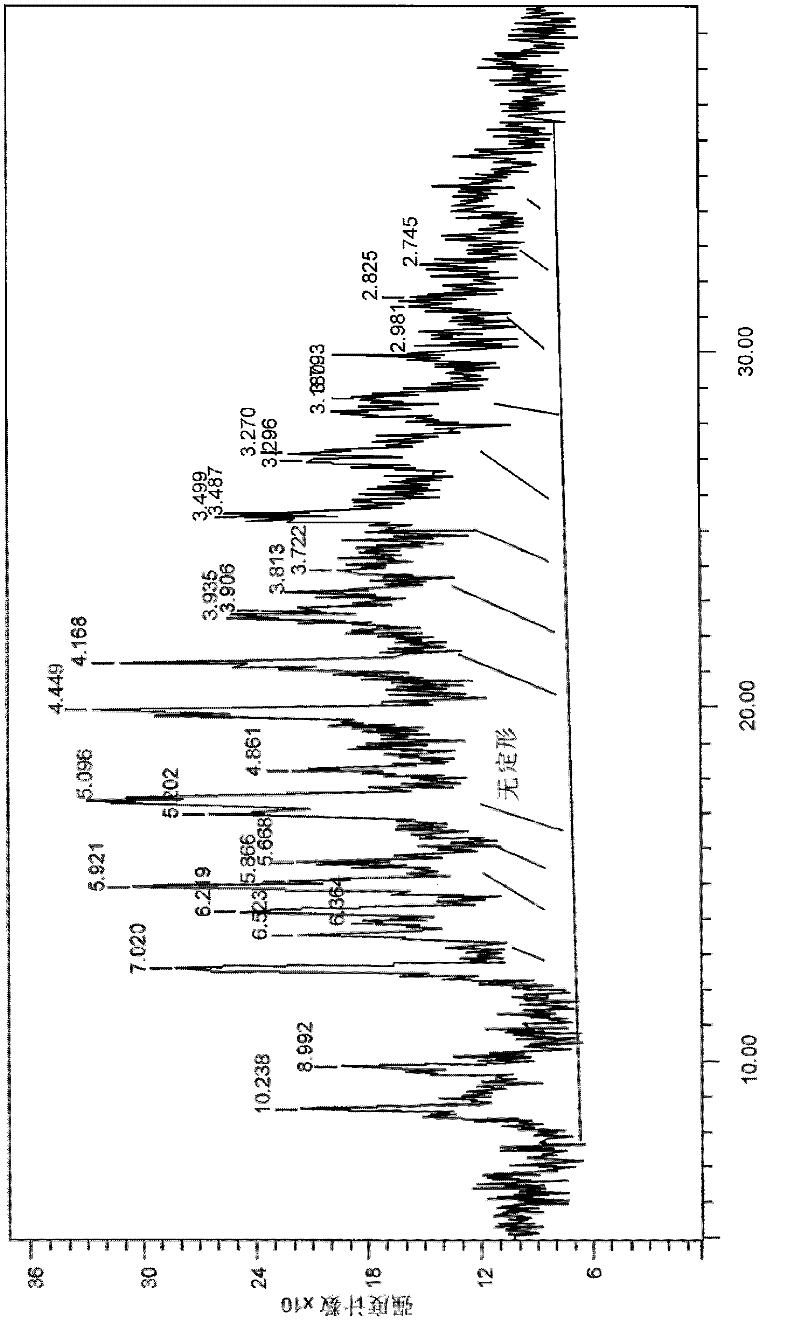

[0140] Reb C (93.3% HPLC purity; ) were placed in each well of a polypropylene 96-well V-bottom plate: well A1, 5.8 mg; well D1, 5.5 mg; well G1, 5.4 mg. Add absolute ethanol (~300 μL 75% of pore volume) to A1, anhydrous methanol (75% of pore volume) to D1, and isopropanol (50% of pore volume) to G1 followed by anhydrous Water methanol (25% of pore volume). The plate was gently agitated until the material in the three wells was completely dissolved. The plates were left uncovered and the solvent was evaporated overnight at room temperature. This produced a glassy, non-crystalline material in all three pores. The material in each well was dissolved again using the same method as above. The 96-well V-bottom plate containing the dissolved Reb C samples was covered with a second blank plate to slow down the evaporation rate and left overnight at room temperature. A colorless / white crystalline solid was obtained in each well. This material was transferred to vials labeled ...

Embodiment 2

[0143] Crude Stevia extract solids or crude Reb C solids (5 g), ethanol (95%, 12.5 mL), methanol (6 mL) and water (2 mL) were combined and heated to reflux for 10 minutes. The clear solution was cooled to 22 °C. The solution was seeded with 10 mg of 93-98% pure Form I Reb C crystals and the mixture was left at 22°C for 16 hours. The resulting white crystalline product was filtered, washed twice with ethanol-methanol (5 mL, 4:1, v / v) mixture and dried in a vacuum oven at 50 °C under reduced pressure (20 mm) for 16-24 hours to obtain The purified Reb C product was obtained. The purity of the Reb C product produced was evaluated by HPLC.

Embodiment 3

[0145] Crude Stevia extract solids or crude Reb C solids (5 g), propanol (95%, 12.5 mL) and methanol (7.5 mL) were combined and heated to reflux for 10 minutes. The clear solution was cooled to 22 °C. The solution was seeded with 10 mg of 93-98% pure Form I Reb C and the mixture was left at 22°C for 16 hours. The resulting white crystalline product was filtered, washed twice with ethanol-methanol (5 mL, 4:1, v / v) mixture and dried in a vacuum oven at 50 °C under reduced pressure (20 mm) for 16-24 hours to obtain The purified Reb C product was obtained. The purity of the Reb C product produced was evaluated by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com