Method for separating and purifying rebaudioside C

A technology for separation and purification of glycosides, applied in the field of food additive production, which can solve problems such as short service life, high cost, and loss, and achieve the effects of simple process, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

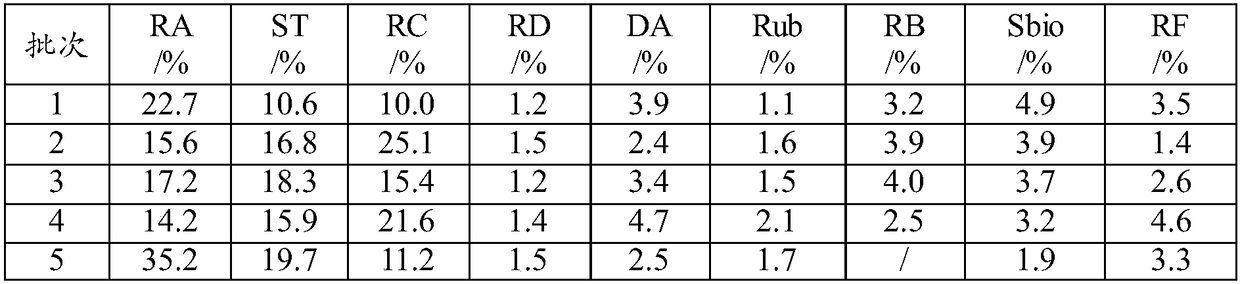

Embodiment 1

[0056] (1) Take 1200g of mother liquor sugar in batch 1, its RC content is 10.0%, add appropriate amount of water to make it 200mg / mL, load the sample with a pump, and flow through a 30cm×50cm chromatographic column (built-in filler Stevia-AX-2) , was eluted with 60% methanol, and the RC component was collected by HPLC detection, concentrated by nanofiltration membrane, and dried to obtain 344 g of dried RC component; wherein the purity of RC was 32%.

[0057] (2) Take the dried RC component obtained in step (1), add 2752 mL of ethanol-acetone-water (10%:70%:20%), dissolve at 70°C, stir and crystallize for 12 hours, filter and dry to obtain primary crystals 136g; the purity of RC is 60%.

[0058] (3) Add 2800 mL of ethanol-methanol-water (10%: 40%: 50%) to the primary crystal obtained in step (2) for secondary recrystallization test, the dissolution temperature is 30°C, let stand for 36h, filter and dry , 78 g of secondary crystals were obtained; the RC purity was 95.7%.

Embodiment 2

[0060] (1) Take 700g of mother liquor sugar in batch 2, whose RC content is 25.1%, add appropriate amount of water to make it 10mg / mL, load the sample with a pump, and flow through a 30cm×50cm chromatographic column (built-in filler Stevia-AX-2) , eluted with 50% methanol, detected and collected RC components by HPLC, concentrated by nanofiltration membrane, and dried to obtain 326 g of dry matter of RC components; wherein the purity of RC was 50%.

[0061] (2) Take the dried RC component obtained in step (1), add 3260 mL of ethanol-acetone-water (30%: 40%: 30%), dissolve at 30°C, stir and crystallize for 36 hours, filter, and dry to obtain primary crystals 144g; the purity of RC is 80%.

[0062] (3) Take the primary crystal obtained in step (2) and add 1160 mL of ethanol-methanol-water (25%: 30%: 45%) for secondary recrystallization test, the dissolution temperature is 70°C, let stand for 12h, filter and dry , 108 g of secondary crystals were obtained; the RC purity was 97.5...

Embodiment 3

[0064] (1) Take 1300g of mother liquor sugar of batch 3, its RC content is 15.4%, add appropriate amount of water to make it 100mg / mL, load the sample with a pump, and flow through a 30cm×50cm chromatographic column (built-in filler Stevia-AX-2) , was eluted with 55% methanol, detected by HPLC to collect RC components, concentrated by nanofiltration membrane, and dried to obtain 442 g of dry matter of RC components; wherein the purity of RC was 41%.

[0065] (2) Take the dried RC component obtained in step (1), add 3575mL ethanol-acetone-water (20%: 60%: 20%), dissolve at 50°C, stir and crystallize for 24h, filter and dry to obtain primary crystals 185g; RC purity 72%.

[0066] (3) Add 1852 mL of ethanol-methanol-water (25%: 40%: 35%) to the primary crystal obtained in step (2) for secondary recrystallization test, the dissolution temperature is 60°C, let stand for 24h, filter and dry , 133.2 g of secondary crystals were obtained; the RC purity was 96.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com