Method for reaction separation purification of rebaudioside A

A technology of reaction and solid-liquid separation, applied in the field of mechanochemistry, can solve problems such as poor specificity, and achieve the effects of reducing pollution, wide application, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

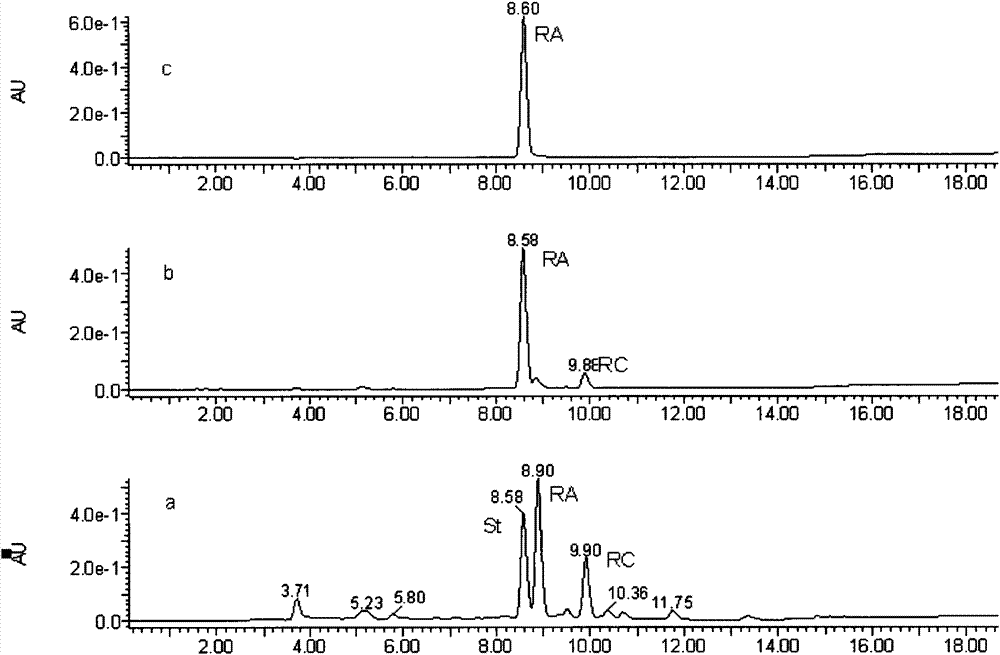

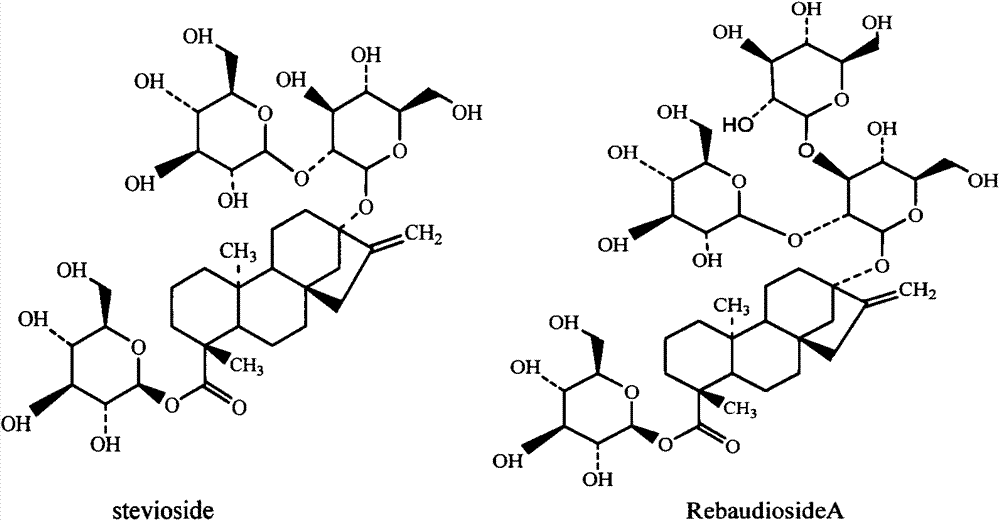

Embodiment 1

[0016] Mix the stevioside crude extract (80% stevioside, 10% rebaudioside A, and the remaining 5% are RC and other impurities) and water at a mass ratio of 1:10, heat and dissolve under stirring until all steviosides are dissolved Afterwards, preheat at 75°C for 30 minutes and add β-galactosidase 600 U / g steveside from Sulfolobus solfataricus to react for 16 hours. The reaction precipitate and the reaction solution are separated into solid and liquid by using a high-speed centrifuge, and the obtained The solid was recrystallized twice with water, and rebaudioside A was precipitated from the water, and dried to obtain rebaudioside A with a purity of 95.1% and a yield of 90.3%. .

Embodiment 2

[0018] Mix the stevioside crude extract (50% stevioside, 46% rebaudioside A, and the remaining 4% are RC and other impurities) and water at a mass ratio of 1:15, heat to dissolve under stirring, and wait until the stevioside is completely dissolved Afterwards, preheat at 75°C for 30 minutes and add β-galactosidase 600 U / g steveside from Sulfolobus solfataricus to react for 16 hours. The reaction precipitate and the reaction solution are separated into solid and liquid by using a high-speed centrifuge, and the obtained The solid was recrystallized twice with water, rebaudioside A was precipitated from the water, and dried to obtain rebaudioside A with a purity of 95.6% and a yield of 90.8%.

Embodiment 3

[0020] Mix the stevioside crude extract (55% stevioside, 35% rebaudioside A, and the remaining 5% is RC and other water-soluble impurities) and water at a mass ratio of 1:10, heat and dissolve under stirring, and wait until the stevioside After all dissolved, add β-galactosidase 600U / g steveside from Sulfolobus solfataricus and react for 16 hours at 75°C preheating for 30 minutes, and separate the reaction precipitate from the reaction liquid by using a high-speed centrifuge for solid-liquid separation. The obtained solid was recrystallized twice with water, and rebaudioside A was precipitated from the water, and dried to obtain rebaudioside A with a purity of 95.5% and a yield of 90.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com