Method for obtaining high-purity stevioside and enriching rebaudioside C from primary crystallization mother liquor of stevioside through secondary crystallization

A technology for crystallizing mother liquor and stevia, which is applied in the field of separation of natural high-intensity sweeteners, and achieves the effects of simple and efficient process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

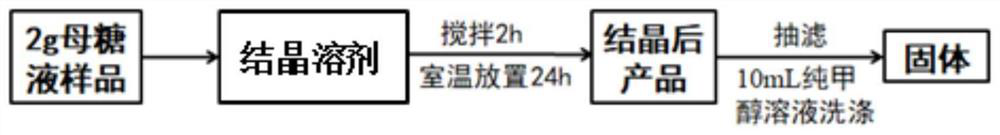

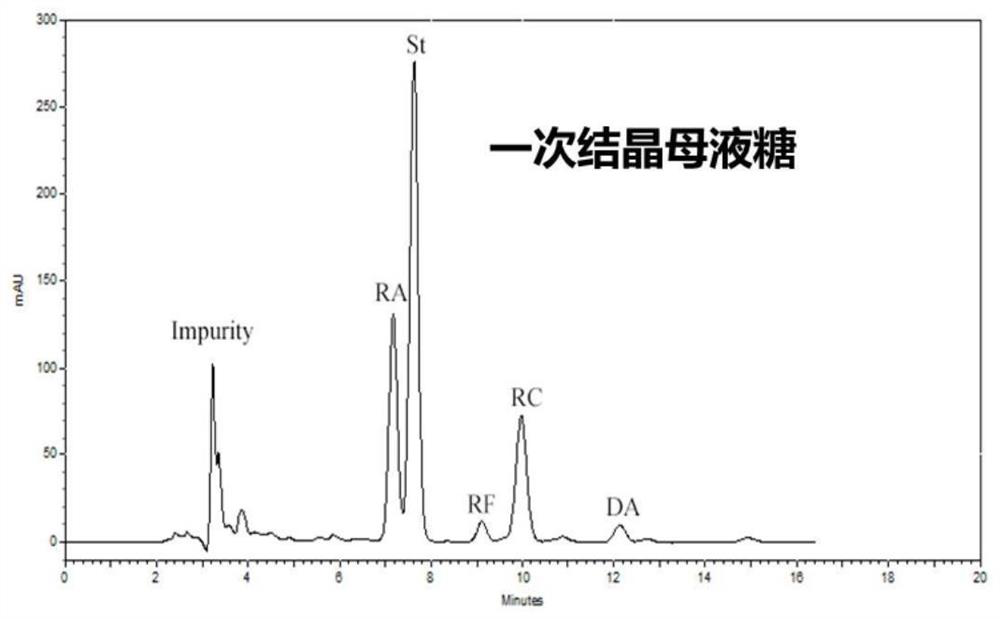

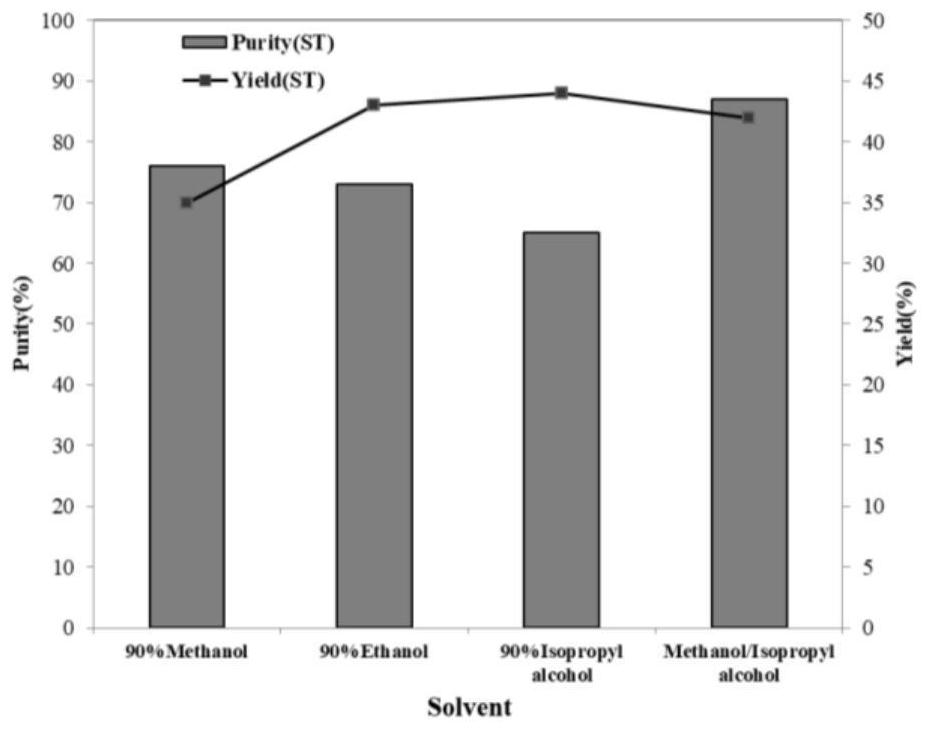

[0030] Precisely measure 100 mL of primary crystallization mother liquor with a pipette, and dry at 100°C to constant weight to obtain a solid. Take 2g of solid for later use, configure 90% methanol and ethanol aqueous solution as the crystallization solvent, put it into a beaker with a solid-to-liquid ratio of 1:8 (g / mL) and stir for 30 minutes, let it stand at 25°C for natural crystallization for 8 hours, and filter the solid for Pure methanol was washed, dried and weighed, and samples were taken for HPLC analysis according to the national standard method.

Embodiment 2~21

[0032] Examples 2-21 of crystallization under different conditions applied to the recovery of high-purity ST are shown in the table below. The parameter condition not mentioned in the form is identical with embodiment 1.

[0033]

[0034]

[0035] In summary, the present invention provides a method for recovering stevioside ST from the primary crystallization mother liquor of industrial stevioside. Utilizing the influence of the crystallization solvent added with isopropanol on the solubility of various substances in stevioside, and selectively recovering ST, this method is simple and efficient, convenient and quick, and removes a part of flavonoid bitter impurities, which provides a basis for the subsequent preparation of high-purity rebaudioside C raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com