Method for transforming stevioside into rebaudioside E

A technology of stevioside and aspergillus niger is applied in the field of food chemical industry to achieve the effect of low cost and easy amplification

Inactive Publication Date: 2012-11-07

成都南诺格生物科技有限责任公司

View PDF4 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] So far, there is no report on the production of Rebaudioside E (Rebaudioside E) by biotransformation with sucrose as the sugar donor by microbial fermentation using stevioside (Stevioside), a single component of steviol glycosides, as a raw material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

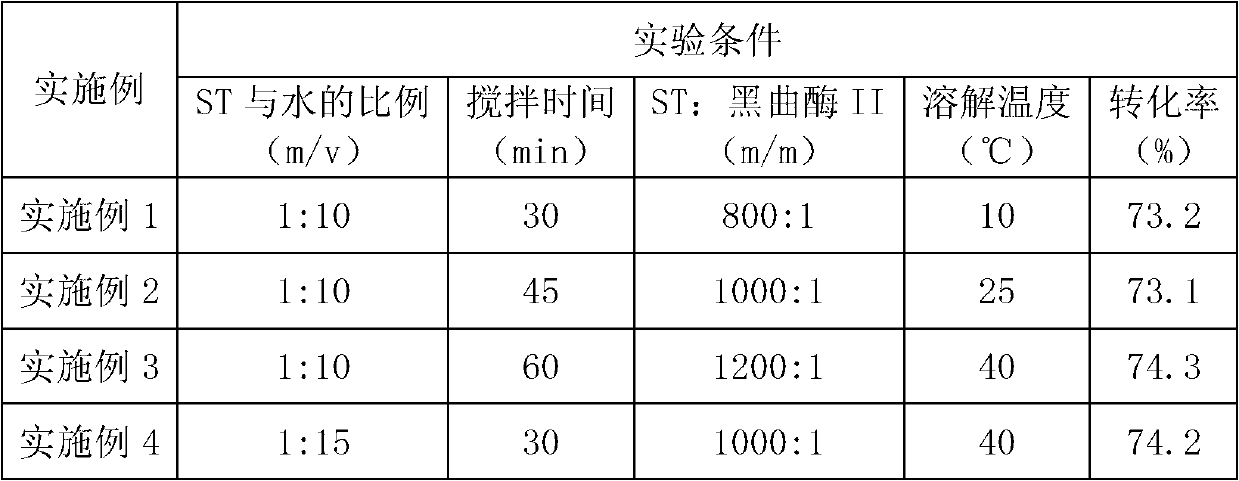

[0033] In a specific embodiment, stevioside (Stevioside) is abbreviated as ST, rebaudioside E (Rebaudioside E) is abbreviated as RE, and sucrose (Sucrose) is abbreviated as SU.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for transforming stevioside into rebaudioside E. The stevioside is transformed into the rebaudioside E by using aspergillns niger II which is added with a sugar source. According to the method, the stevioside is used as a raw material to obtain a transformation rate of the rebaudioside E, the transformation rate of the rebaudioside E is larger than and identical to 70%, the rebaudioside E content in solid matters can at least reach to 60%, after a further separation and purification, the rebaudioside E content can reach to 80% and is even larger than 90%, the rebaudioside E is free from extraneous odour, similar to cane sugar and capable of being used as a sweetener independently, the rebaudioside E production cost is low, and the method is easy to magnify and suitable for industrial production.

Description

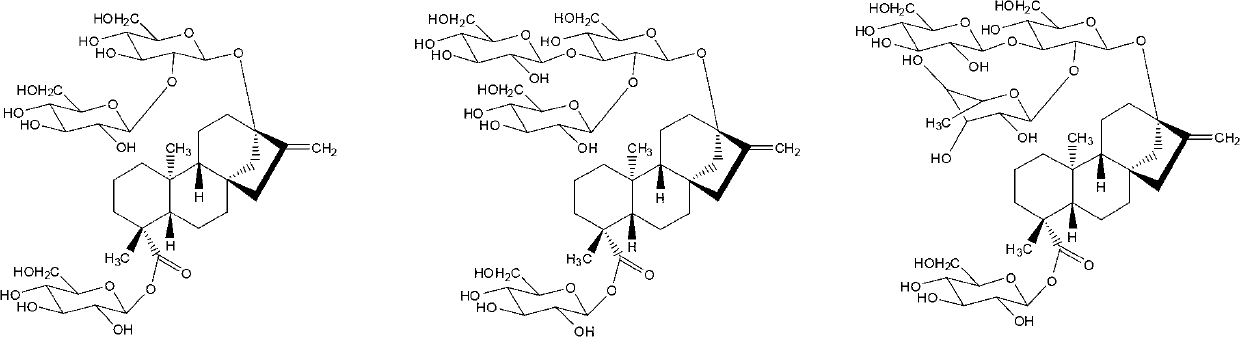

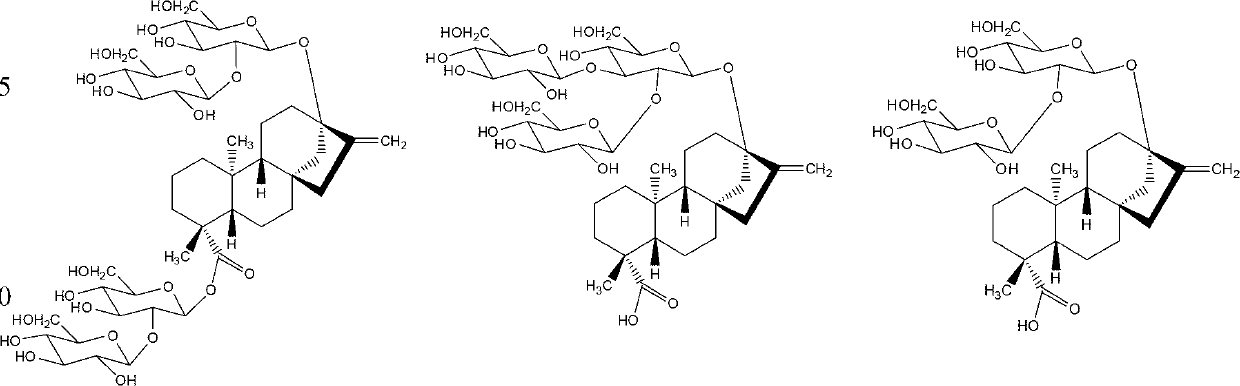

technical field [0001] The invention belongs to the field of food chemical industry, and in particular relates to a method for converting stevioside into rebaudioside E. Background technique [0002] Steviol glycosides (Steviol glycosides) is a general term for stevia extracts. Its sweet ingredients include stevioside (Stevioside), rebaudioside A, B, C, D, E (Rebaudioside A / B / C / D / E), steviolbioside (Steviolbioside), dulcoside A (Dulcoside A), etc. In traditional steviol glycosides, stevioside accounts for about 66% of the total glycosides, rebaudioside A accounts for about 22% of the total glycosides, rebaudioside C accounts for about 9% of the total glycosides, and dulcoside A accounts for about 2% of the total glycosides, and the content of other components is very small. The structural formula of the main components of steviol glycosides is as follows: [0003] [0004] Stevioside Rebaudioside A Rebaudioside C [0005] [0006] Rebaudioside E Rebaudioside ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C12P19/56C12R1/685

Inventor 李沁桐欧阳劲

Owner 成都南诺格生物科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com