Cut-tobacco drier based on independent tobacco cutting characteristics of papermaking method reconstituted tobacco and cut-tobacco drying control method thereof

A technology of reconstituted tobacco leaves and shred drying machine, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of not taking into account the influence of physical characteristics and chemical characteristics, sensory characteristics, decline in use quality, and unproposed problems, so as to improve quality and effectively Effects of utilization rate, improvement of sensory properties, and maintenance of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

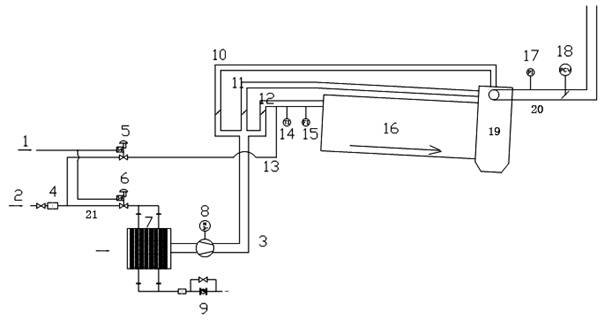

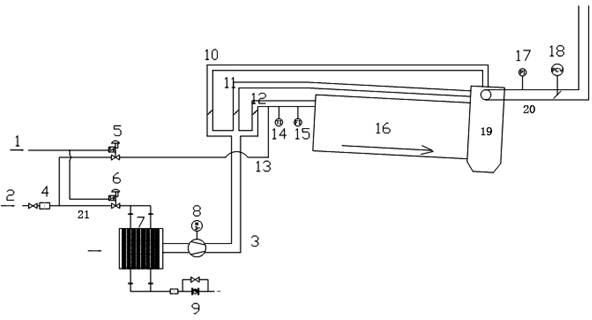

[0028] like figure 2Shown is a shred drying machine based on the paper-making method to reconstitute the characteristics of individual shredded tobacco leaves. The shred dryer includes a cylinder body 16, a moisture removal transfer screen 19, a hot air system for drying shreds, a humidifying air system and a control system. The front end of the cylinder 16 is provided with an air inlet, and the moisture-discharging transfer net 19 is arranged at the rear end of the cylinder 16, and the moisture-discharging transfer net 19 is provided with a moisture-discharging air duct 20, and the silk drying heating air system includes a heat exchanger 7. The hot air blower 8 and the air pipe 3, the air pipe 3 collects the hot air passing through the surface of the heat exchanger 7, the described hot air blower 8 is arranged on the air pipe 3, the described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com