Technique for fermentation production of fruit vinegar beverage by utilizing orange peel residue

A technology of citrus peel and fruit vinegar drink, which is applied in the preparation, application, and food preparation of vinegar, and can solve the problems of poor utilization of citrus peel and achieve easy microbial utilization, excellent sensory properties, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of technology of citrus peel dregs fermenting and producing fruit vinegar stoste, carries out according to the following steps:

[0031] 1) Raw material selection: choose fresh, no mildew, no rot, and citrus peels after squeezing the juice as raw materials;

[0032] 2) Crushing: add water at a ratio of twice the weight of citrus peels, and crush to make the crushed peels as fine as possible, which is beneficial to the enzymatic hydrolysis process;

[0033] 3) Enzymolysis: add 0.06%-0.08% (by mass percentage) compound enzyme to the crushed citrus peel, and incubate at 27°C-32°C for 2.5-3 hours for enzymolysis. The mass ratio of the compound enzyme is 5:1 composition of French Raman pectinase and Shibi cellulase;

[0034] 4) Sugar content adjustment: add sugar to the above-mentioned citrus peel residue system after enzymatic hydrolysis to adjust the sugar content, so that the alcohol content reaches 4.0%-6.0% (in terms of volume percentage concentration); add anal...

Embodiment 2-5

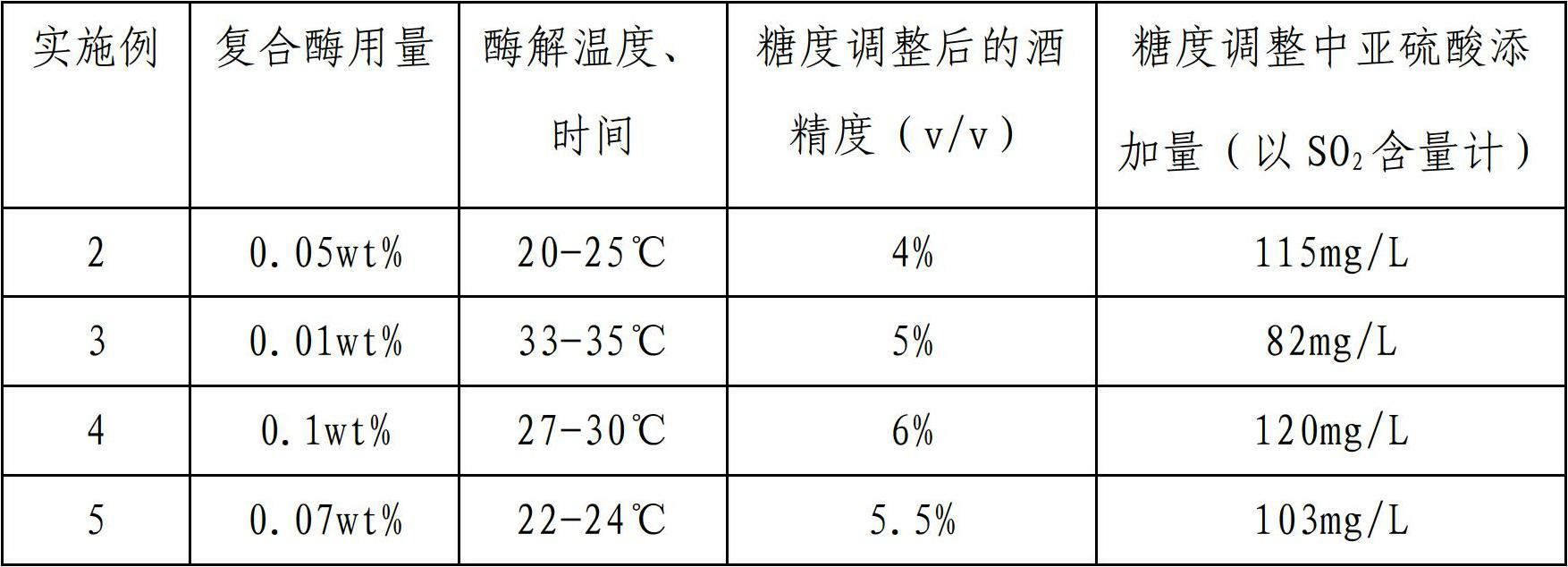

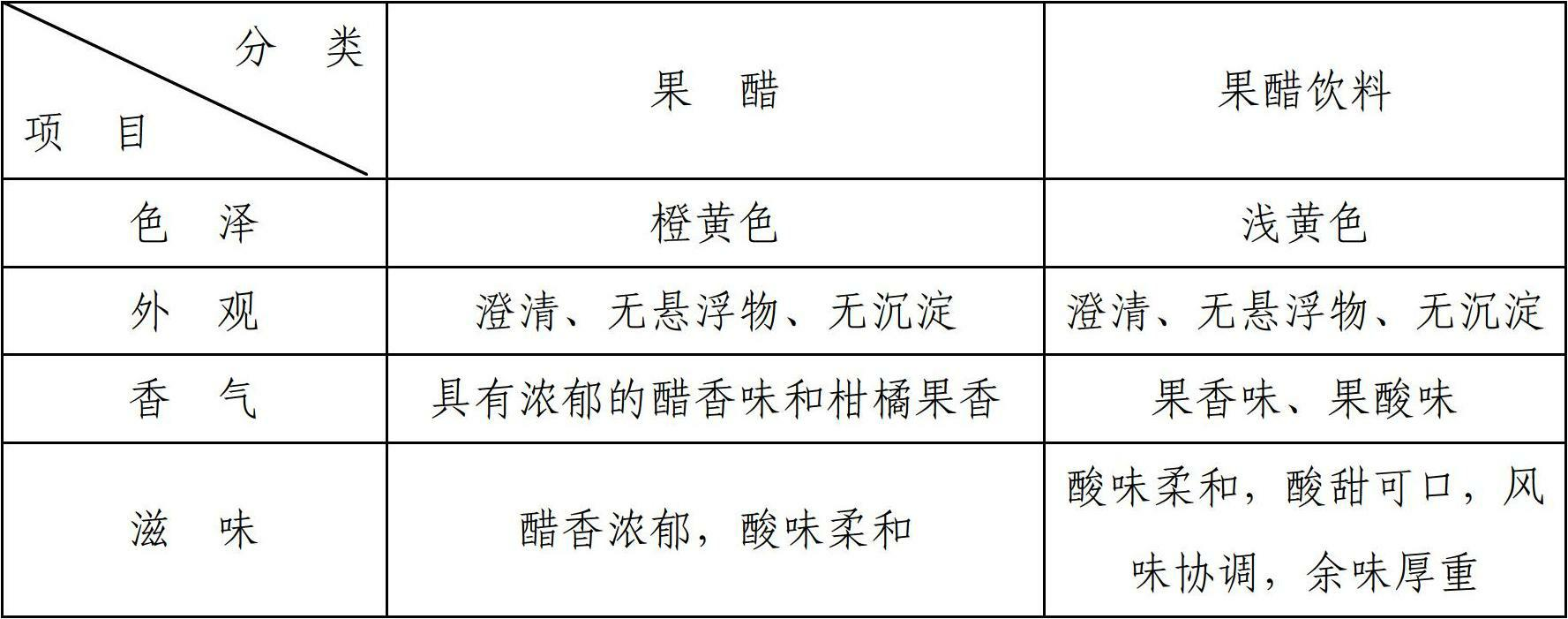

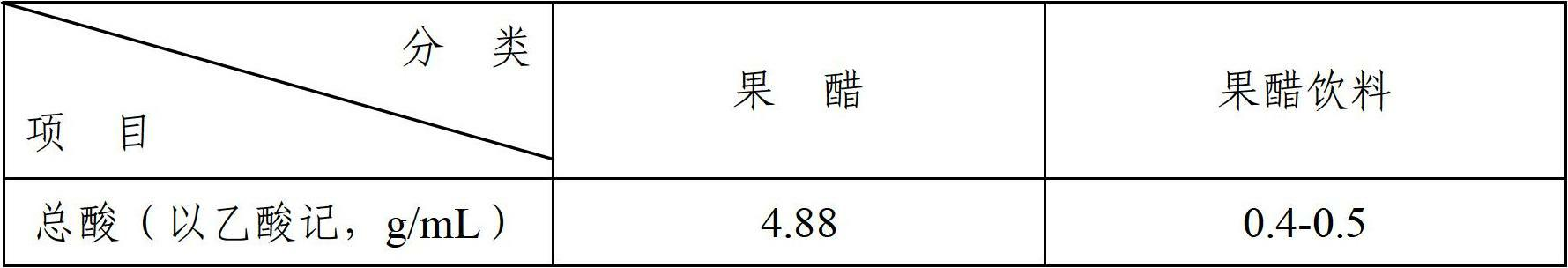

[0041] Embodiment 2-5: Carry out according to the following steps and process parameters, and the rest are the same as embodiment 1.

[0042]

[0043] The production process of the above-mentioned fruit vinegar stock solution has low cost, high production efficiency, and high conversion rate of citrus peels. 1 ton of crushed citrus peel raw materials can produce 5.8-6.3 tons of citrus fruit vinegar stock solution, and the acetic acid content is as high as 4.0-4.67%. (in terms of mass percent concentration).

Embodiment 6

[0045] A kind of technology that utilizes citrus peel dregs to ferment to produce fruit vinegar beverage, carries out according to the following steps:

[0046] 1) Raw material selection: select 1 ton of citrus peel residues that are fresh, free from mildew, non-rotten, and squeezed as raw materials;

[0047] 2) Crush: add water in proportion to twice the weight of citrus peel, and crush;

[0048] 3) Enzymolysis: add 0.06%-0.08% compound enzyme to the pulverized citrus peel residue, in terms of mass percentage, and incubate at 27°C-32°C for 2.5-3 hours for enzymolysis. The compound enzyme has a mass ratio of 5 : 1 composition of French Raman pectinase and Shibi cellulase;

[0049] 4) Sugar content adjustment: add sugar to the enzymatically hydrolyzed citrus peel system to adjust the sugar content, so that the alcohol content reaches 4.0%-6.0%, in terms of volume percentage concentration; add analytically pure sulfurous acid, and use sulfur dioxide content in the The addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com