French fry scoop

a scoop and scoop technology, applied in the field of scoops for picking up french fries, can solve the problems of contaminating the host of contamination and safety issues, increasing the weight and size of the scoop, and reducing the likelihood of excess fries, reducing the likelihood of fries, and minimizing or eliminating both sanitary and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

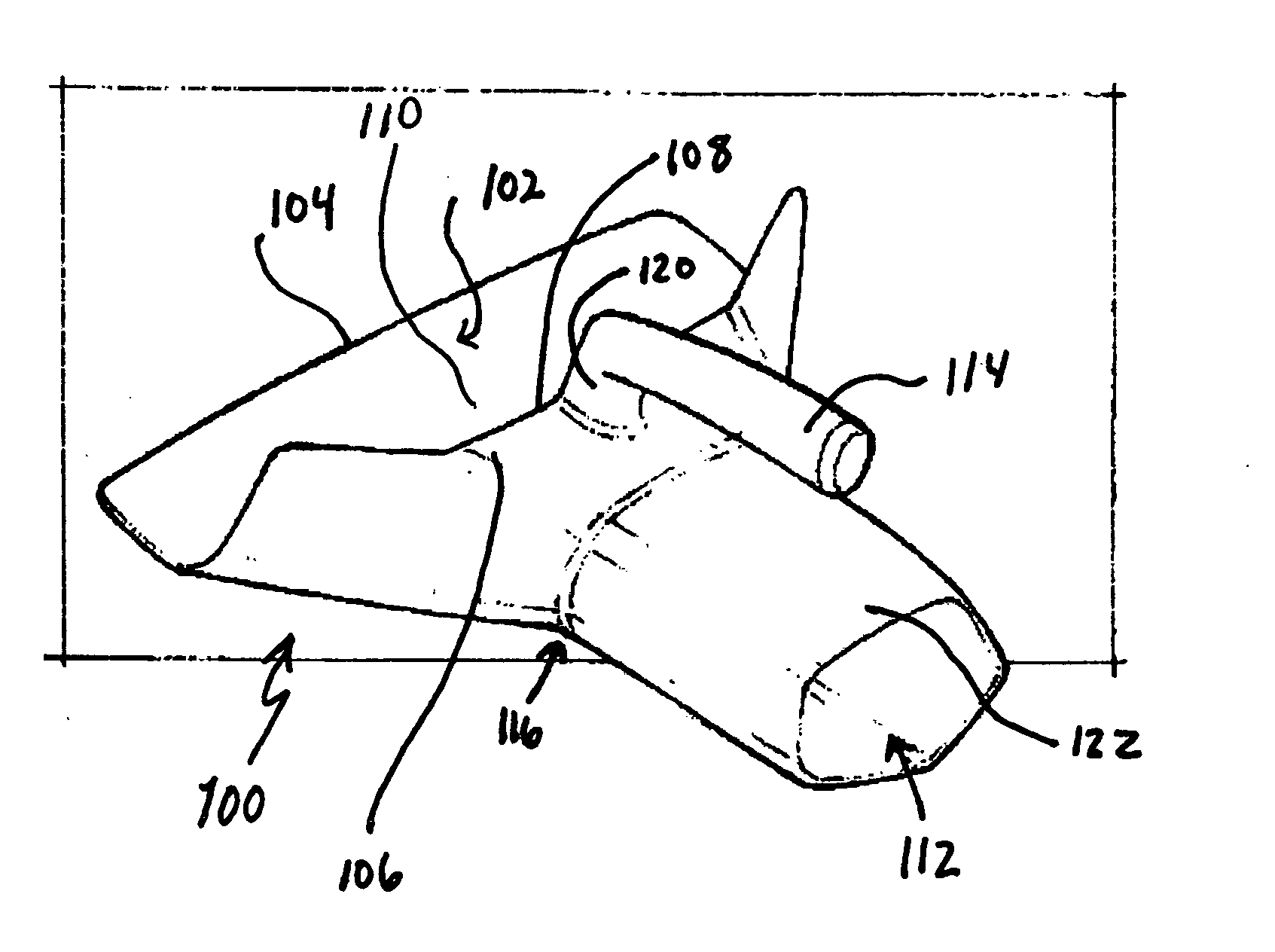

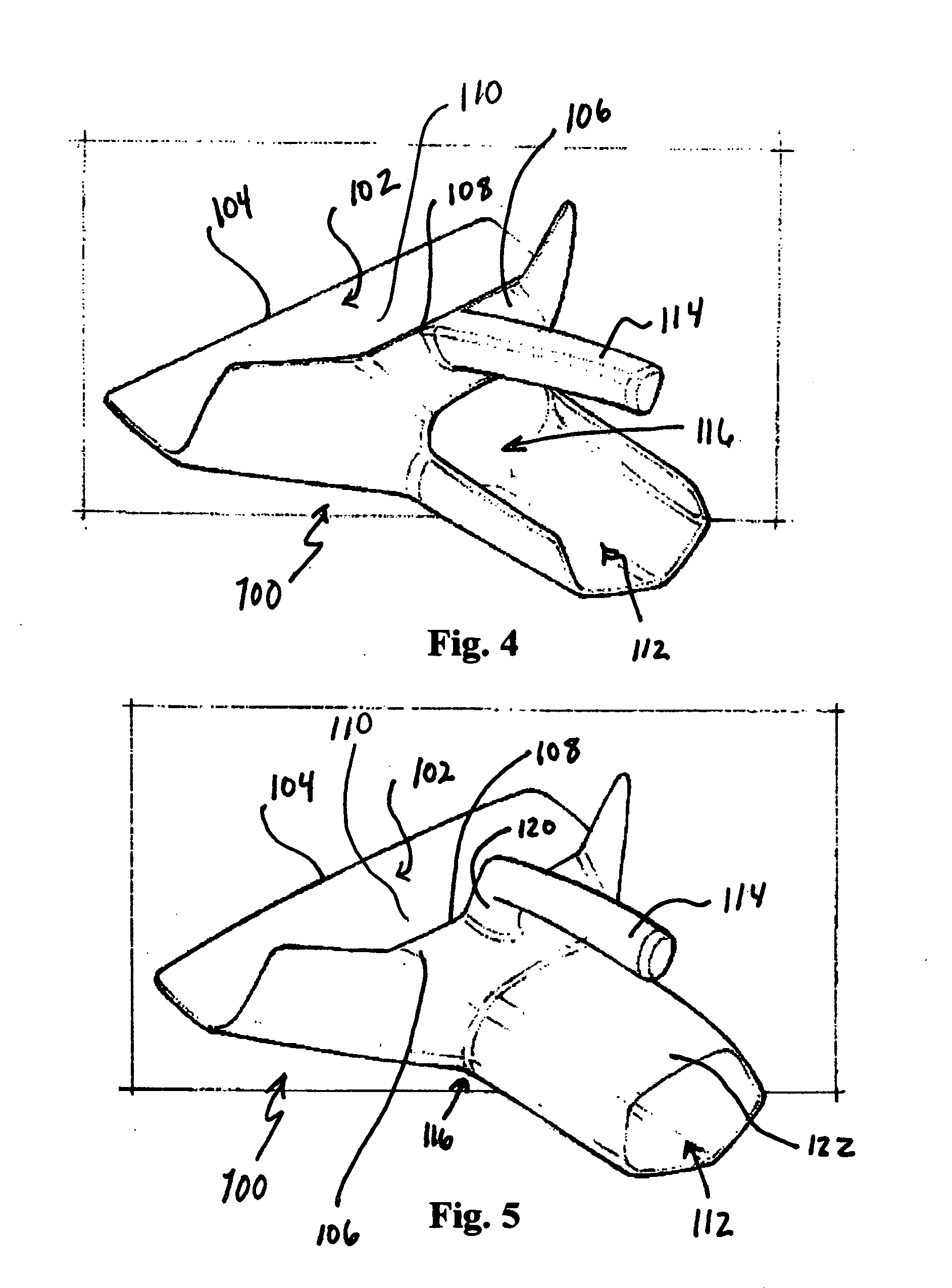

[0029] As shown in FIGS. 4-12 and 15, the present invention comprises a scoop 100 having a front mouth portion 102 with a wide top leading edge 104. A hood or cover portion 106, which has its top edge 108 set back relative to the leading edge 104, may serve to partially enclose the mouth portion 102. The bottom 110 of the mouth portion 102 tapers through a throat 116 into a dispensing funnel 112. A handle 114 preferably extends from the cover portion 106.

[0030] As shown in FIGS. 5, 10-11 and 15, the cover portion may also include a shield member 118 that extends from and above the cover portion 106. As can be seen, the shield member 118 may take a number of forms. More specifically, as shown in dotted lines in FIGS. 10 and 11, the shield may run substantially the length of the top edge 108 of the cover portion or may run only a portion of the cover portion.

[0031] In other preferred embodiments of the present invention, as shown in FIGS. 7 and 8, the handle 114 is angled horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com