Preparation method of reshaped compound fruit and vegetable crisp chips

A technology for fruit and vegetable chips, fruit and vegetable chips, applied in the directions of food drying, food science, etc., can solve the problems of reduced puffing degree, unbalanced nutrition and high energy of pressure-difference puffed fruit and vegetable chips, so as to improve the glass transition temperature and avoid harmful effects. Substance generation, porous structure stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

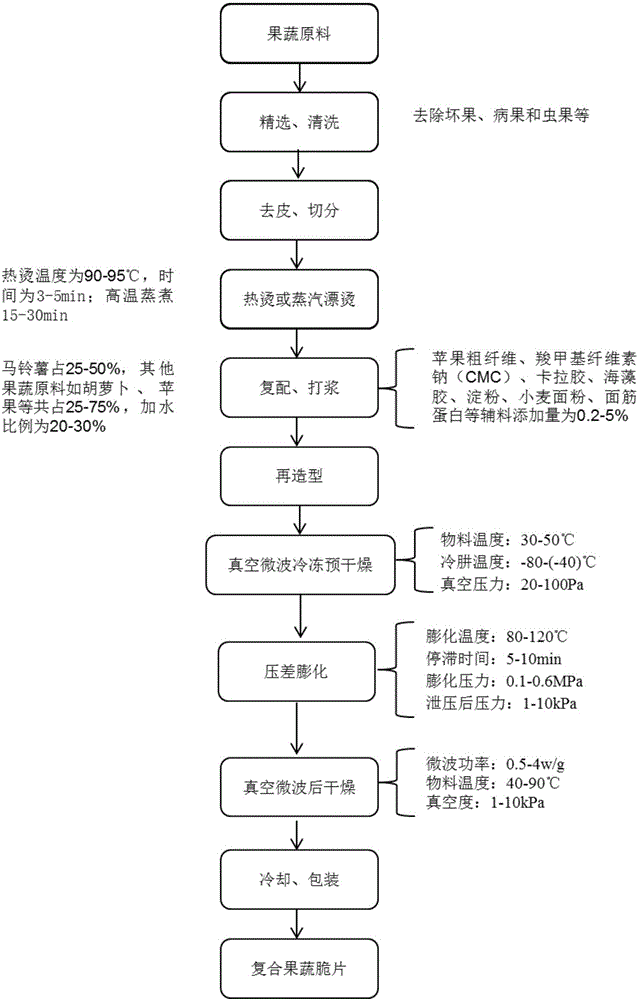

[0039] Such as figure 1 As shown, the present invention provides a kind of preparation method of remodeling compound fruit and vegetable chips, it is characterized in that, comprises the following steps:

[0040] Step 1, pretreating various fruit and vegetable raw materials, mixing auxiliary materials and beating to obtain composite fruit and vegetable pulp;

[0041] Step 2, reshaping the composite fruit and vegetable pulp into composite fruit and vegetable slices;

[0042] Step 3. The composite fruit and vegetable slices are pre-dried by vacuum microwave freeze until the water content is 20-50%. The method of vacuum microwave freeze pre-drying is: put the reshaped composite fruit and vegetable slices in the processing chamber and carry out vacuum drying at the same time. Freeze drying and microwave heating of materials, and at the same time, use the condensation of cold hydrazine to absorb moisture in the air, so that the moisture content of the material can be reduced to 20...

Embodiment 1

[0065] One, the preparation method of composite fruit and vegetable chips comprises the following steps:

[0066] (1) Fruit selection and cleaning: select potatoes, carrots, bananas, strawberries and tomatoes without mildew, rot and insect eyes, and rinse with water for 6 minutes;

[0067] (2) Peel and cut into pieces, cut the raw material into 1cm material and cut it into selected mold-free small pieces;

[0068] (3) Heat treatment: The above-mentioned fruit and vegetable raw materials were blanched with steam for 30 minutes, so that the starch in the raw materials was fully gelatinized, and at the same time achieved the effect of inactivating enzymes; strawberries and tomatoes did not need to be blanched with steam, and were used directly;

[0069] (4) Compounding and beating: compound potatoes, carrots, bananas, strawberries, and tomatoes according to the weight ratio of 4:3:1:1:1, add apple crude fiber and carrageenan to the compound fruit and vegetable puree, and the addi...

Embodiment 2

[0108] The preparation method of composite fruit and vegetable chips in this embodiment is basically the same as the steps in Example 1, except that:

[0109] (1) Fruit selection and cleaning: select potatoes, carrots, apples and pears without mildew, rot, or insect eyes, and rinse with water for 4 minutes;

[0110] (2) Peel and cut into pieces, cut the raw material into 1cm material and cut it into selected mold-free small pieces;

[0111] (3) Heat treatment: scald potatoes, carrots and pears with steam for 15 minutes respectively, so that the starch in the raw materials is fully gelatinized, and at the same time achieve the effect of inactivating enzymes; among them, the raw materials of apples and peaches do not need heat treatment;

[0112] (4) Compounding and beating: compound potatoes, carrots, apples, peaches and pears in a weight ratio of 4:2:2:2:2, and add high-gluten wheat flour and sodium carboxymethylcellulose (CMC) to the compound fruits and vegetables In the mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com