Process for producing vermicelli from sweet potato

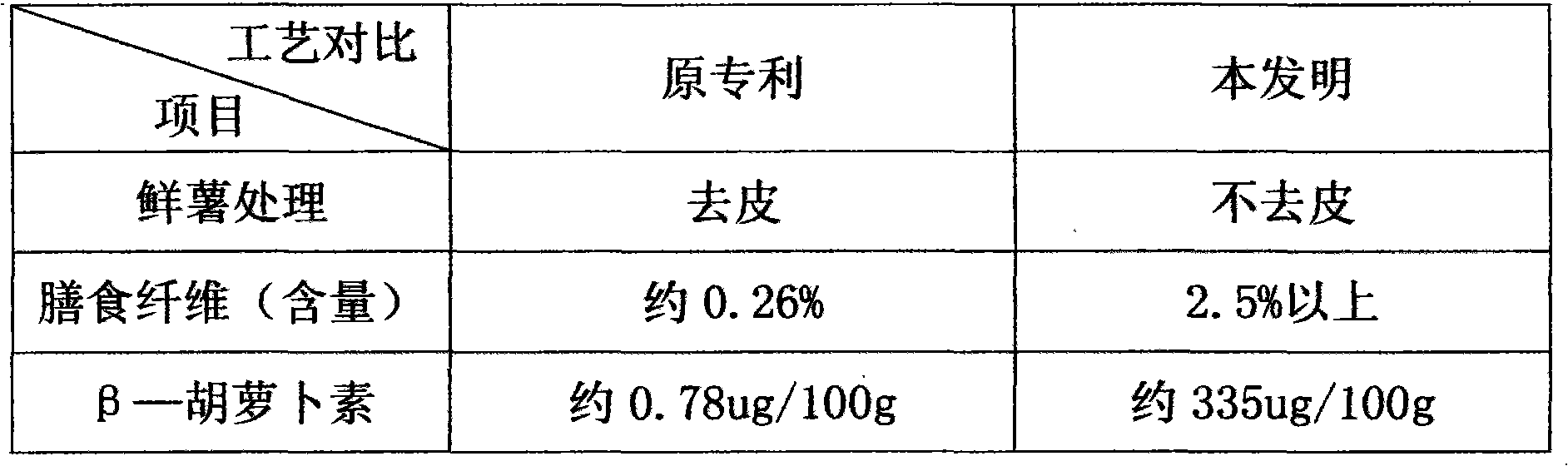

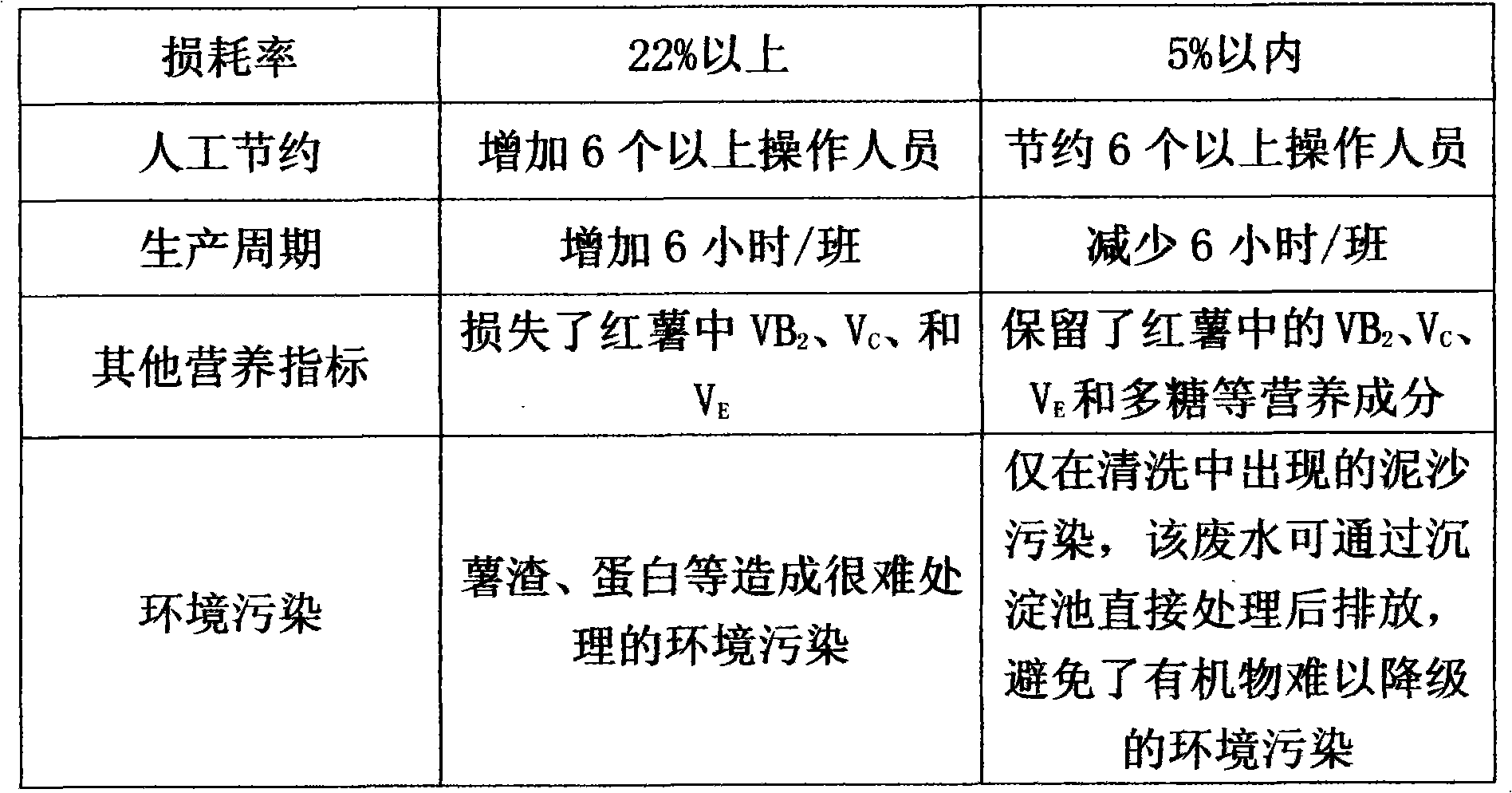

A processing method and technology of vermicelli, applied in the processing field of whole potato vermicelli, can solve problems such as lowering product quality, many production processes, affecting product quality, and production efficiency, so as to reduce residual sulfur dioxide, reduce manual production operations, and benefit health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A processing method of whole potato vermicelli mainly consists of the following steps:

[0038] a. Fresh potatoes (sweet potatoes, potatoes, cassava or other fresh potatoes) are cleaned with clean water;

[0039] b. Potato pulp preparation: Fresh potatoes are transported through the trough conveyor belt, sorted manually or mechanically, and remove frostbite, rotten fresh potatoes or fresh potato bud eyes and other impurities. Fresh potatoes are not peeled and then crushed, ground or a combination of the two Make potato pulp, the diameter of particles in the potato pulp is 1-500 microns;

[0040] c. Ingredients and ingredients: take 100 parts of potato pulp, 20200 parts of potato dry starch, 0.1-10 parts of modified starch, and 0-20 parts of water respectively according to the weight ratio, and put them into the powder mixing machine for mixing Stir well;

[0041] d. Maturation and forming: put the uniformly mixed materials into the self-cooking vermicelli machine or e...

Embodiment 2-9

[0047] A processing method of whole potato vermicelli, wherein the ingredient composition (unit: parts by weight) is shown in the following table:

[0048]

[0049] Other techniques, steps, parameters are identical to embodiment 1, omitted.

Embodiment 10

[0051] A method for processing whole potato vermicelli, the step (a) adopts dried potatoes, and in the step (b) of preparing potato pulp, the dried potatoes are used and crushed to make dried potato powder and mixed with water at a weight ratio of 1:2-5. Become potato pulp; Others are with embodiment 1, 2, 3, 4, 5, 6, 7, 8 or 9, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com