Egg paste mixing and stirring device for flour processing

A technology for mixing and stirring egg noodles, which is applied to dough mixers, mixing/kneading with vertical installation tools, structural components of mixing/kneading machines, etc. Problems such as the inability to automatically cut the egg shell, etc., to achieve the effect of uniform distribution and avoid displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

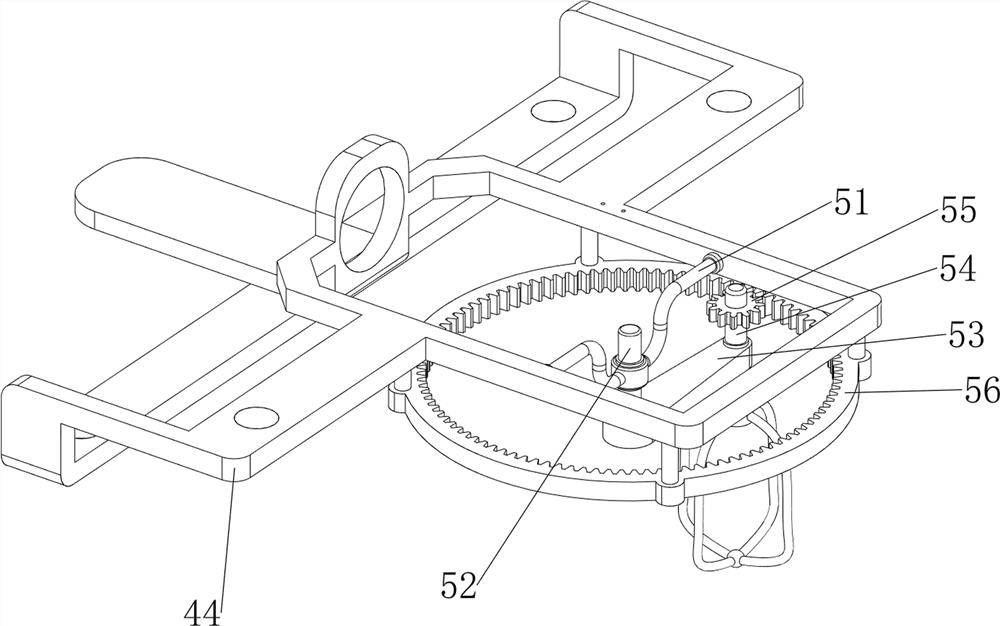

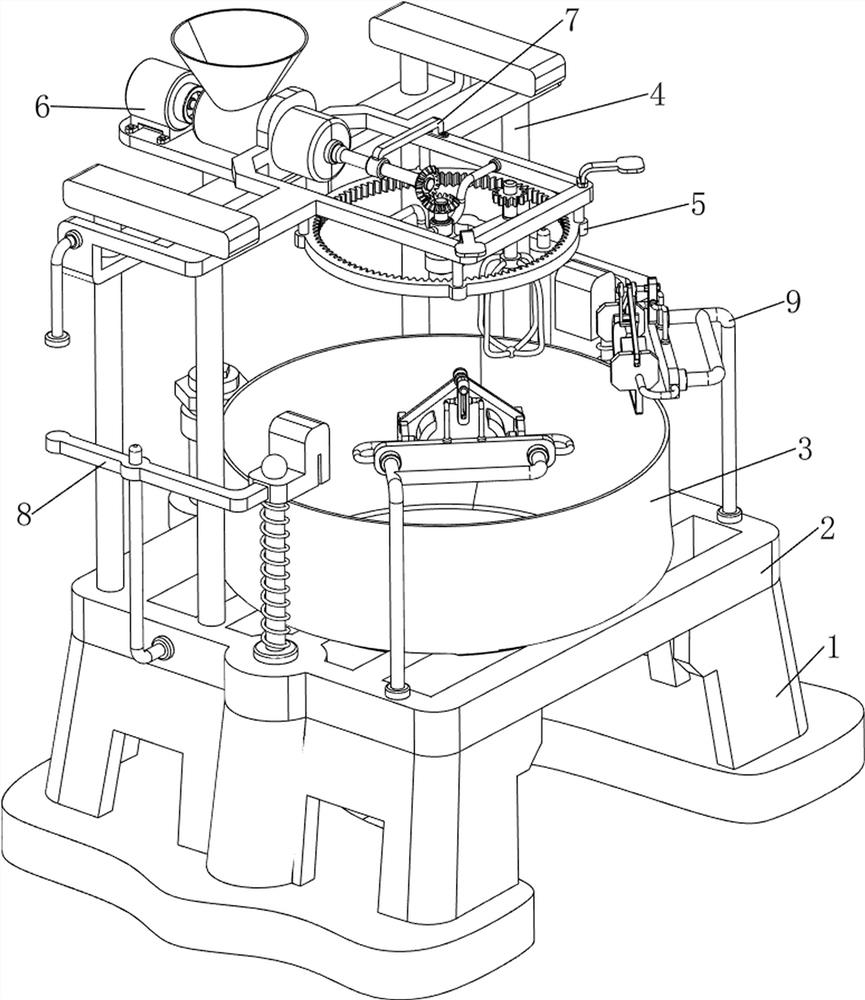

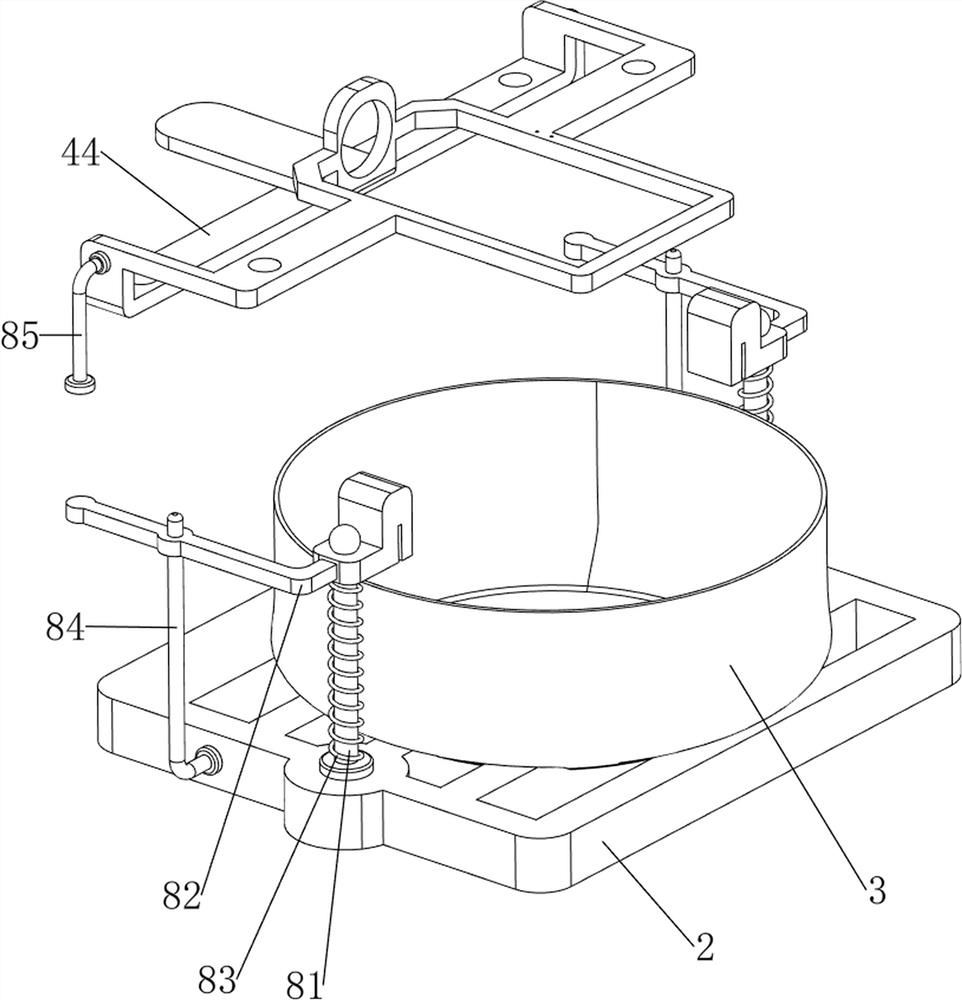

[0064] An egg batter mixing and stirring device for flour processing, such as Figure 1-Figure 3 As shown, it includes a base 1, a workbench 2, a mixing box 3, a lifting mechanism 4 and a stirring mechanism 5. The base 1 is provided with a workbench 2, the top of the workbench 2 is placed with a mixing box 3, and the top of the workbench 2 is provided on the rear side. Lifting mechanism 4 is arranged, and stirring mechanism 5 is arranged on lifting mechanism 4.

[0065]When people want to stir eggs and flour, they can use this egg batter mixing and stirring device for flour processing. First, the user pours the flour into the mixing box 3. After the flour is poured, the egg white is poured into the mixing box 3. In the mixing box 3, flour and egg white are mixed together, and the user activates the lifting mechanism 4. When the lifting mechanism 4 falls to a certain height, the user turns the stirring mechanism 5, and the stirring mechanism 5 pairs the flour and egg white in t...

Embodiment 2

[0071] On the basis of Example 1, such as Figure 4-Figure 7 As shown, a first blanking mechanism 6 is also included, and the first mounting frame 44 is provided with a first blanking mechanism 6, and the first blanking mechanism 6 includes a blanking box 61, a feed port 62, and a discharge port 63 , the third rotating shaft 64, screw blade 65 and motor 66, the motor 66 is installed on the rear side of the top of the first mounting frame 44, the rear side of the first mounting frame 44 top is provided with a blanking box 61, and the blanking box 61 is positioned at the motor 66 front, The middle part of the feeding box 61 is rotatably provided with a third rotating shaft 64, the third rotating shaft 64 is connected with the output shaft of the motor 66, the third rotating shaft 64 is provided with a spiral blade 65, and the rear side of the feeding box 61 top is provided with a feeding port 62, A discharge opening 63 is provided on the front side of the bottom of the lower mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com