Wet preparation method of instant corn nutrition snowflake tablets

A technology for snowflakes and corn is applied in the field of wet preparation of instant corn nutritional snowflakes, which can solve the problems of affecting starch gelatinization characteristics, reducing the content of resistant starch, affecting the reconstitution of products, and the like, so as to retain nutrients and flavors. Substances, improved reconstitution, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the present embodiment, the process steps of preparing instant corn nutritional snow flakes are as follows:

[0037] (1) Raw material pretreatment

[0038] Select the dry corn grits prepared as raw materials to obtain dry corn grits with normal color, no mildew, no insects, and no peculiar smell;

[0039] (2) Soak

[0040] Measure 50 kilograms of dry corn grits for soaking from the dry corn grits after the pretreatment in step (1), put it into a stirring tank and add 100 kilograms of tap water at 30 ° C, soak for 4 hours under stirring, and the stirring speed is 2r / min, then remove the soaking water;

[0041] (3) Refining

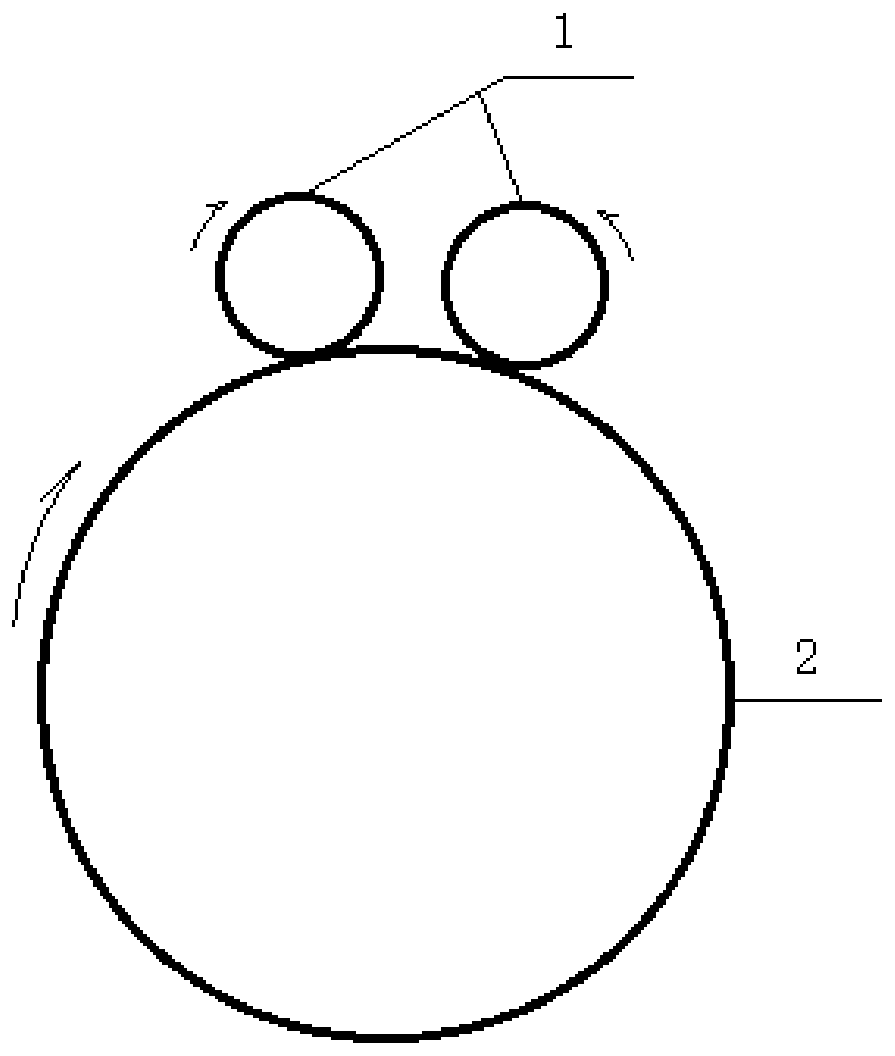

[0042] Transport the soaked corn grits to the colloid mill hopper by a screw conveyor and add tap water to refine through the colloid mill. The distance between the rotor and the rotor, the fineness of the pulp is controlled to be 150 mesh;

[0043] (4) Pre-gelatinization and pre-drying

[0044] Pregelatinize and predry the corn slurry obtai...

Embodiment 2

[0054] In the present embodiment, the process steps of preparing instant corn nutritional snow flakes are as follows:

[0055] (1) Raw material pretreatment

[0056] Select the dry corn grits prepared as raw materials to obtain dry corn grits with normal color, no mildew, no insects, and no peculiar smell;

[0057] (2) Soak

[0058] Measure 50 kilograms of dry corn grits for soaking from the dry corn grits after the pretreatment in step (1), put it into a soaking tank, add 100 kilograms of distilled water at 40° C. to soak for 3 hours, and then remove the soaking water;

[0059] (3) Refining

[0060] Transport the soaked corn grits to the colloid mill hopper through a screw conveyor and add distilled water to refine through the colloid mill. The distance between the rotor and the rotor, the fineness of the pulp is controlled to be 100 mesh;

[0061] (4) Pre-gelatinization and pre-drying

[0062] Pregelatinize and predry the corn slurry obtained by refining with two pairs ...

Embodiment 3

[0072] In the present embodiment, the process steps of preparing instant corn nutritional snow flakes are as follows:

[0073] (1) Raw material pretreatment

[0074] Select the dry corn grits prepared as raw materials to obtain dry corn grits with normal color, no mildew, no insects, and no peculiar smell;

[0075] (2) Soak

[0076] Measure 30 kilograms of dry corn grits for soaking from the dry corn grits after the pretreatment in step (1), put it into a jacketed pot, add 60 kilograms of tap water at 50° C. to soak for 2.5 hours, and then remove the soaking water;

[0077] (3) Refining

[0078] The soaked corn grits are transported to the colloid mill hopper by a screw conveyor, and tap water is added to carry out defibrination through the colloid mill. The distance between the rotor and the rotor, the fineness of the pulp is controlled to be 120 mesh;

[0079] (4) Pre-gelatinization and pre-drying

[0080] Pregelatinize and predry the corn syrup obtained by refining wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com