Process for producing instant breakfast samp

A production process and production process technology are applied in the production process field of instant breakfast corn flakes, and can solve the problems of insufficient crispness, poor instant taste, different product taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

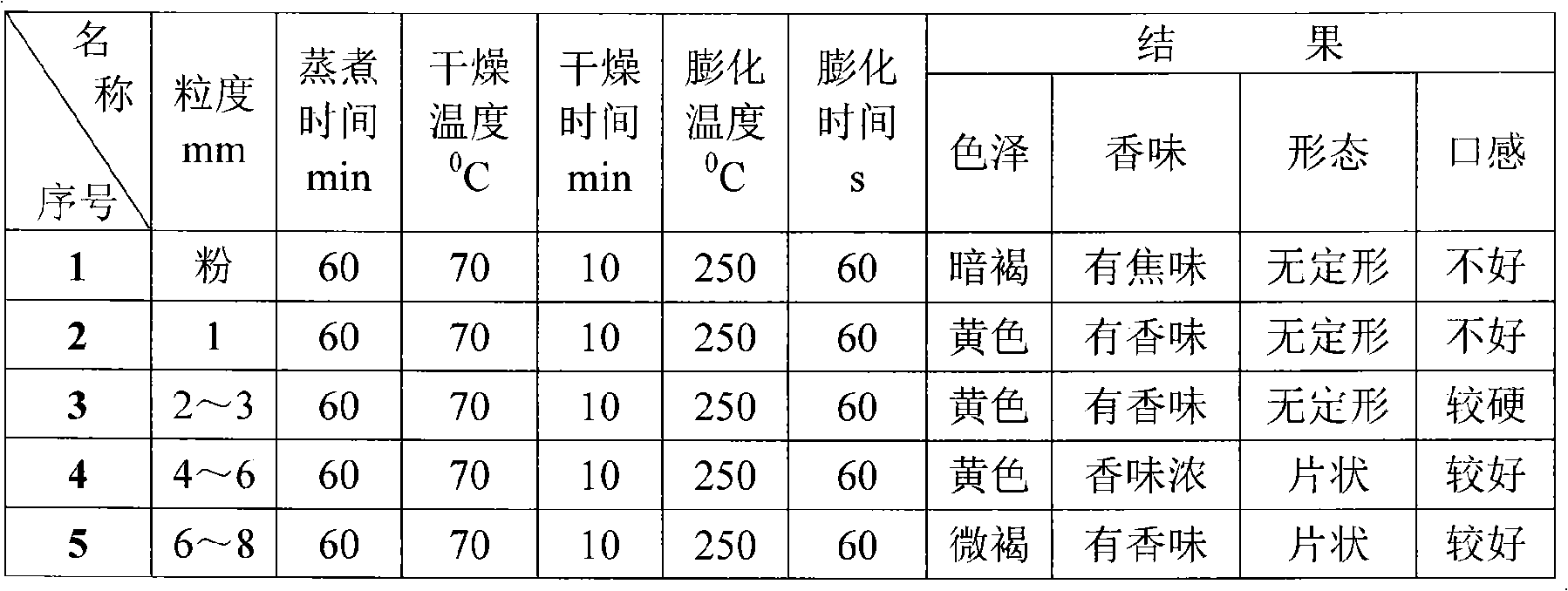

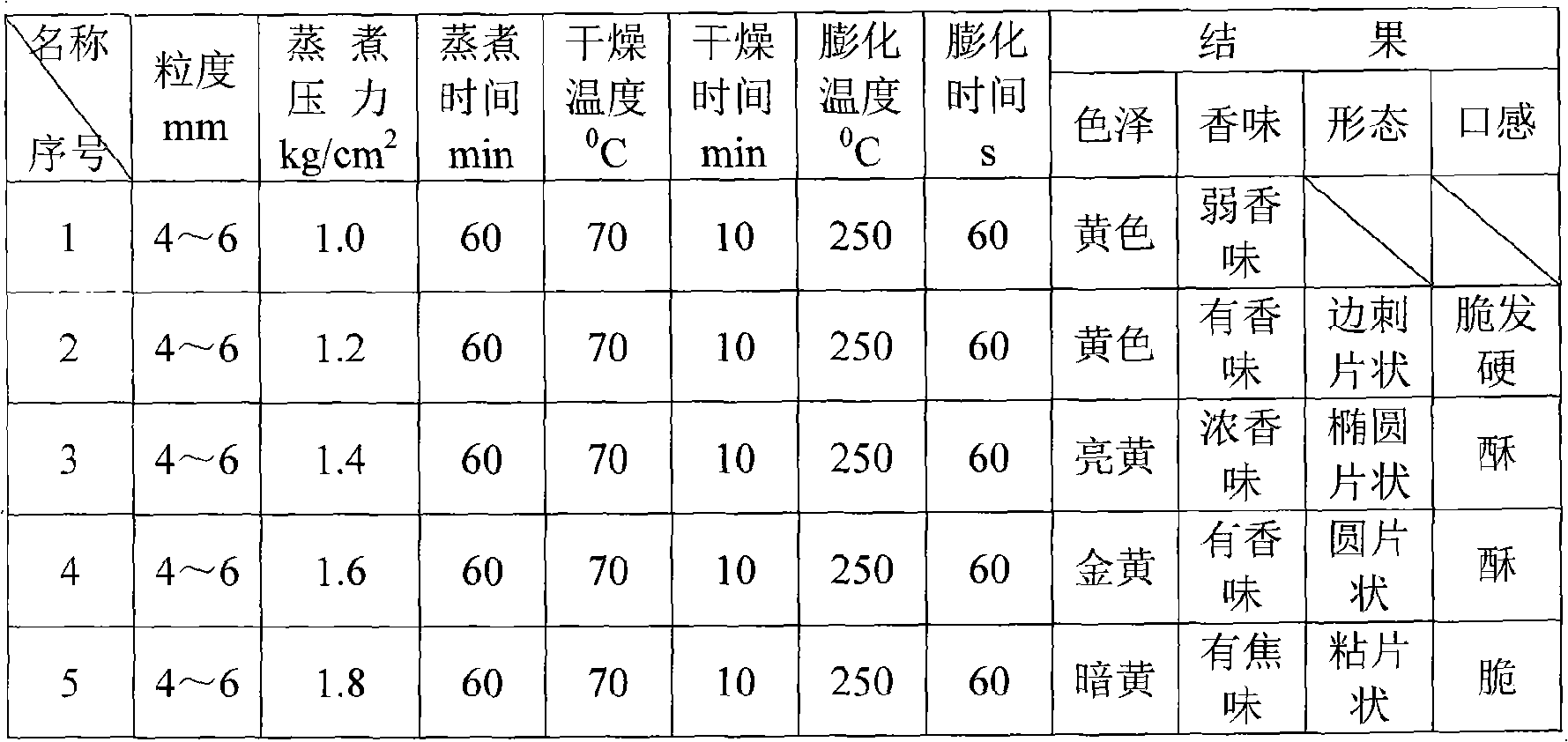

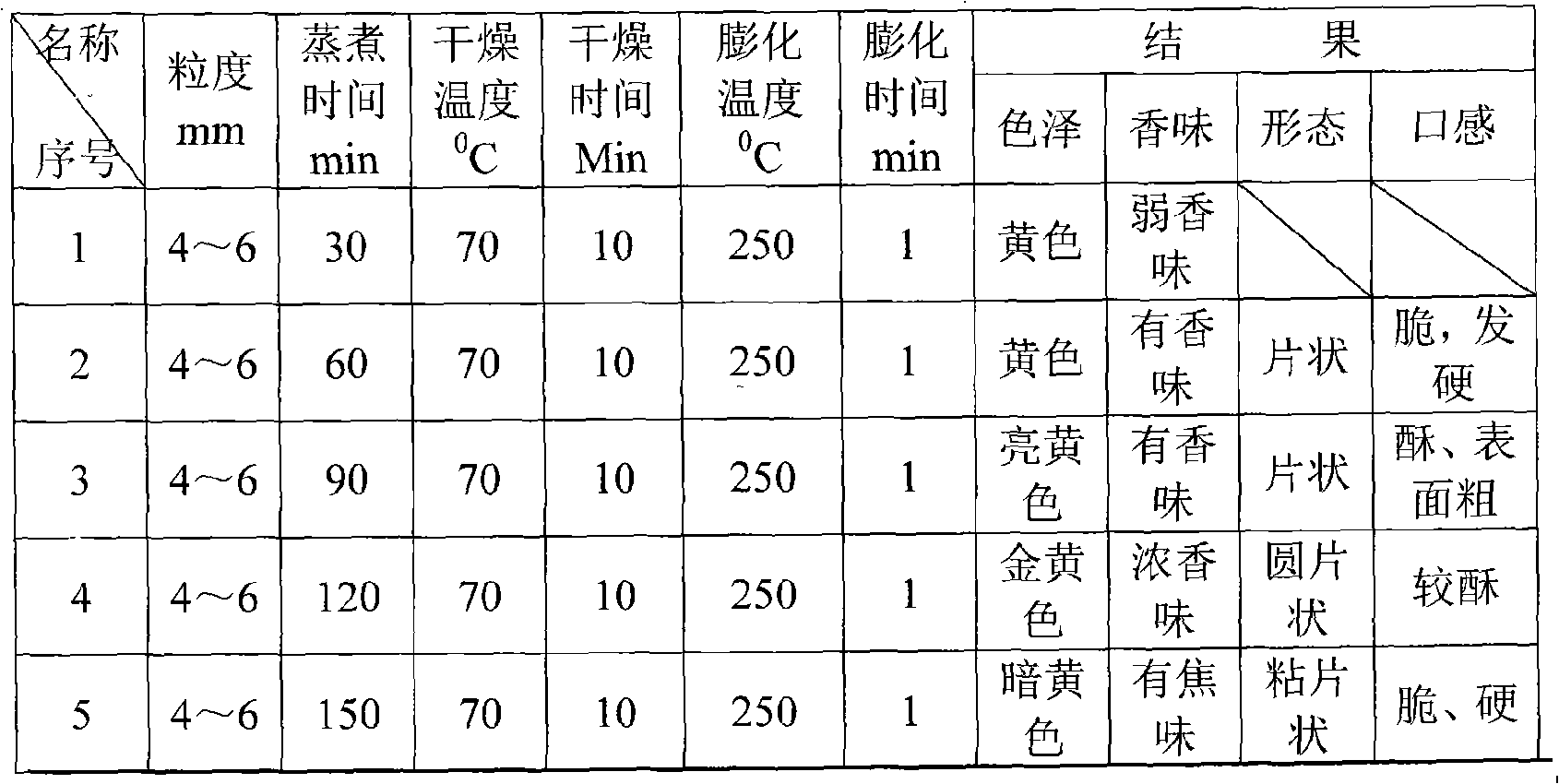

Method used

Image

Examples

Embodiment ( 1

[0084] 1. Selection of raw materials: choose yellow corn or white corn with no mildew, no insect erosion, normal color and odor, and a germination rate of not less than 85%. The maximum fat content is 4.8-5.0% (dry basis), and the maximum fatty acid is 25%. . The maximum impurity content of pre-treated corn should not exceed 3%, the damaged corn should not exceed 5%, the maximum moisture content should not exceed 14%, and the lowest point of vitreous rate should reach 50%.

[0085] 2. Cleaning: iron impurities are removed by magnetic separator, large and small impurities are removed by rotary screen, stones and mud blocks are removed by suction stone remover, and light impurities are removed by suction separator.

[0086] 3. Peeling, degermination and grading: The cleaned corn is adjusted for moisture by a humidifier. After the corn is adjusted by moisture, the skin embryo can be increased in moisture, which is easy to separate the embryo and the endosperm. The speed of the d...

Embodiment ( 2

[0097] 1. Raw material selection: choose yellow corn or white corn with no mildew, no insect erosion, normal color and smell, and a germination rate of not less than 85%. The maximum fat content is 4.8-5.0% (dry basis), and the fatty acid is at most 25%. . The maximum impurity content of pre-treated corn shall not exceed 3%, the maximum content of damaged corn shall not exceed 5%, the maximum moisture content shall not exceed 14%, and the minimum vitreous rate shall reach 50%.

[0098] 2. Cleaning: Remove iron impurities by magnetic separator, remove large and small impurities by rotary sieve, remove stones and mud by suction stone remover, and remove light impurities by suction separator.

[0099] 3. Peeling, degerming and grading: After cleaning, the corn is regulated by the humidity control machine. After the corn is regulated by moisture, the skin germ can increase the moisture, which is easy to separate the germ and endosperm. The speed of the degerminator is 610 rpm whe...

Embodiment ( 3

[0110] 1. Raw material selection: choose yellow corn or white corn with no mildew, no insect erosion, normal color and smell, and a germination rate of not less than 85%. The maximum fat content is 4.8-5.0% (dry basis), and the fatty acid is at most 25%. . The maximum impurity content of pre-treated corn shall not exceed 3%, the maximum content of damaged corn shall not exceed 5%, the maximum moisture content shall not exceed 14%, and the minimum vitreous rate shall reach 50%.

[0111] 2. Cleaning: Remove iron impurities by magnetic separator, remove large and small impurities by rotary sieve, remove stones and mud by suction stone remover, and remove light impurities by suction separator.

[0112] 3. Peeling, degerming and grading: After cleaning, the corn is regulated by the humidity control machine. After the corn is regulated by moisture, the skin germ can increase the moisture, which is easy to separate the germ and endosperm. The speed of the degerminator is 610 rpm whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Amount of water | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com