Continuous synchronous microwave enzyme inactivation and drying device and method for grain germ

A technology for inactivating enzymes and grains by microwave is applied in the direction of storing seeds by drying and heating, etc. It can solve the problems of small processing capacity of wheat germ, and achieve the effect of large processing capacity and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

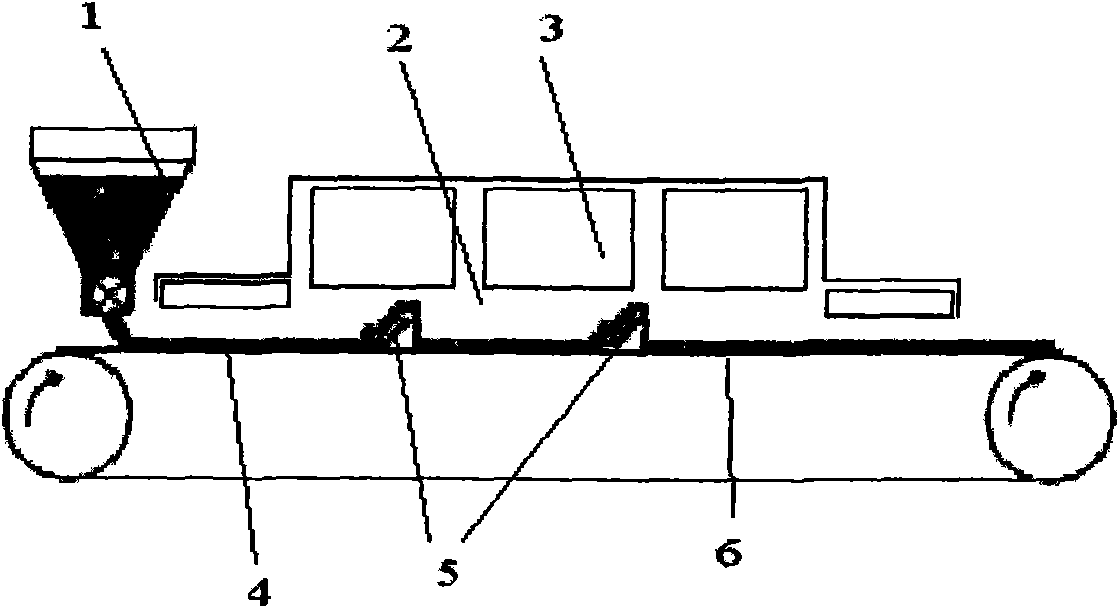

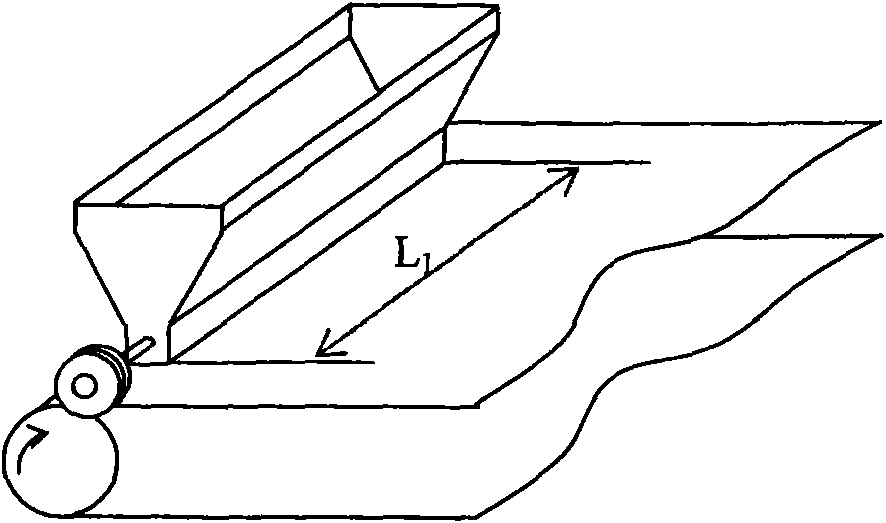

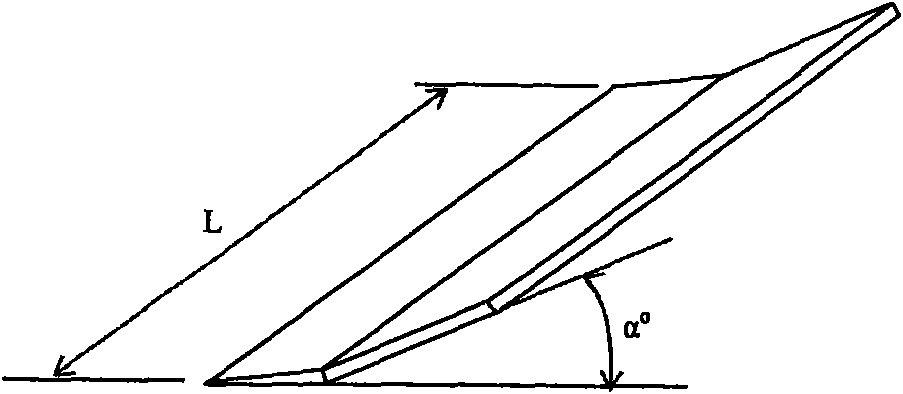

[0019] Application of the present invention in microwave enzyme inactivation and drying rice bran: fresh rice bran enters the conveyor belt 6 through the feeder 1, and the rice bran enters the conveyor belt 6 evenly by adjusting the number of revolutions of the feeder 1 and the transmission speed of the conveyor belt And keep the material layer evenly paved into a thick and thin layer with a thickness of 0.8cm, to ensure uniform heating, turn on the microwave generator 3 to carry out microwave heating to kill enzymes and microwave drying at the same time, the rated power of the microwave tunnel is 6kW, and the processing capacity is about 40kg rice bran per hour; Driven by the conveyor belt 6, it passes through the microwave tunnel 2 at a uniform speed, and the enzyme inactivation and drying treatment are obtained. The embryo turner 5 is installed on the conveyor belt 6, and the material layer on the conveyor belt 6 is turned by the embryo turner 5, which is convenient for micro...

Embodiment 2

[0023] Application of the present invention in microwave enzyme inactivation and drying rice bran: fresh rice bran enters the conveyor belt 6 through the feeder 1, and the rice bran enters the conveyor belt 6 evenly by adjusting the number of revolutions of the feeder 1 and the transmission speed of the conveyor belt And keep the material layer evenly paved into a thick and thin layer with a thickness of 1.2cm, to ensure uniform heating, turn on the microwave generator 3 to carry out microwave heating to kill enzymes and microwave drying at the same time, the rated power of the microwave tunnel is 2kW, and the processing capacity is about 60kg rice bran per hour; Driven by the conveyor belt 6, it passes through the microwave tunnel 2 at a uniform speed, and the enzyme inactivation and drying treatment are obtained. The embryo turner 5 is installed on the conveyor belt 6, and the material layer on the conveyor belt 6 is turned by the embryo turner 5, which is convenient for micro...

Embodiment 3

[0027]Application of the present invention in microwave enzyme inactivation and drying wheat germ: fresh wheat germ enters the conveyor belt 6 through the feeder 1, and the wheat germ enters evenly by adjusting the number of revolutions of the feeder 1 and the transmission speed of the conveyor belt Conveyor belt 6 and keep the material layer uniformly paved into a 1cm thick layer to ensure uniform heating. Turn on the microwave generator 3 for microwave heating to kill enzymes and microwave drying at the same time. The rated power of the microwave tunnel is 2kW, and the processing capacity is about 40kg of wheat germ per hour. The wheat germ passes through the microwave tunnel 2 at a uniform speed under the drive of the conveyor belt 6, and has obtained enzyme-killing and drying treatments. Layer, which is convenient for the timely distribution of hot and humid air generated during microwave heating and ensures uniform heating of the material layer. Finally, measure the moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com